Predictive Inventory Planning

AI-powered shipment forecasting that predicts delivery dates with 95% accuracy, reducing expedite costs by 30% and improving customer satisfaction.

Challenge

Single-family contract customers must predict appliance shipments weeks to months ahead without reliable updates from builders. Teams juggle ERP, EDI feeds, email threads, and spreadsheets. Current forecasts show ~15% error at 4 weeks and ~80% at 6 weeks, causing missed installs, excess buffer inventory, expediting fees, and low customer satisfaction.

The objective: Reduce 4-week error to ≤8% and 6-week error to ≤25%; deliver ≤18% MAPE schedules for 3–6 months ahead; auto-update ≥70% of PO lines with confidence-based routing and compliant system updates.

Solution: How AIP changed the operating model

Learning and setup

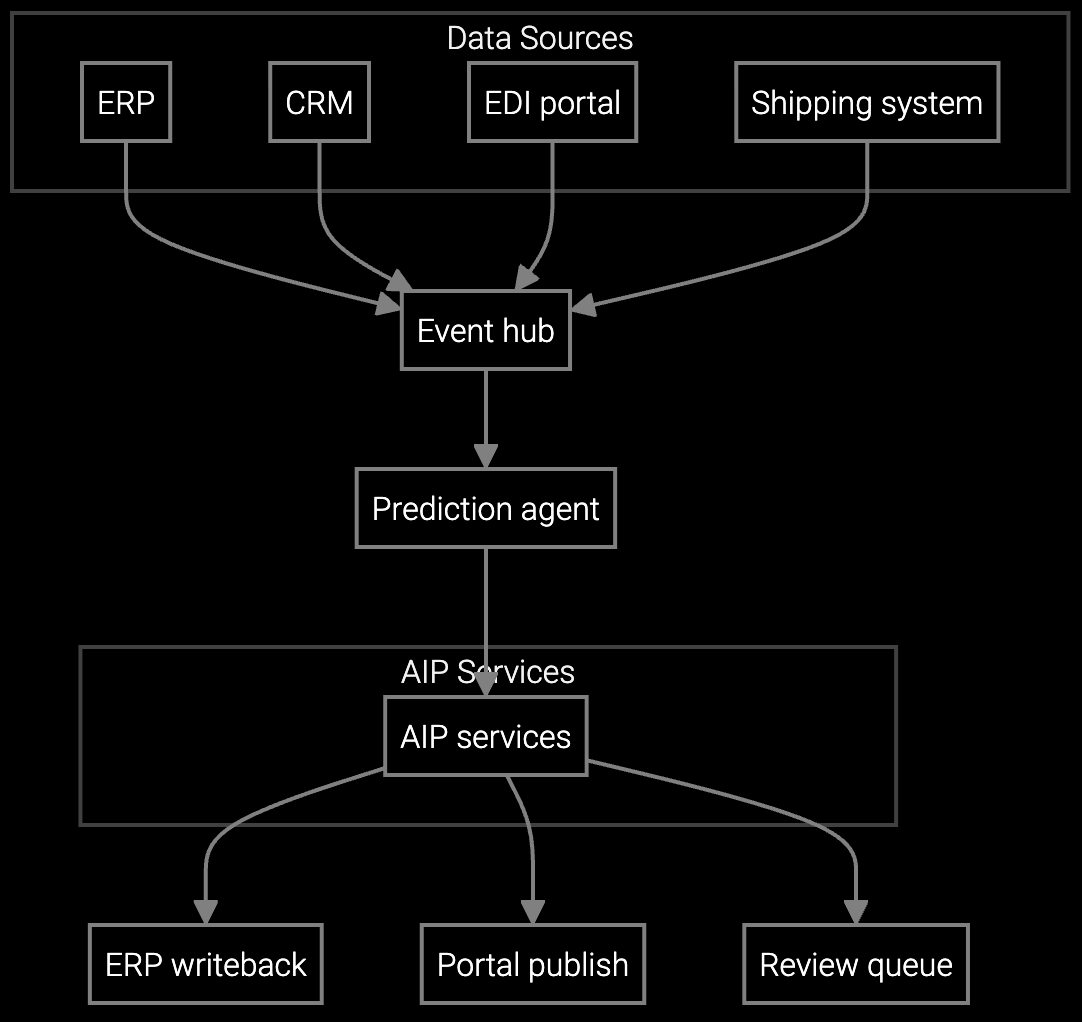

Powered by the Aftermarket Intelligence Platform (AIP), the agentic solution applied its predictive and forecasting models with ontology-driven feature engineering. Training data came from purchase order and shipment history, order change logs, EDI acknowledgements, SKU attributes and lead times, carrier SLAs, holiday and seasonality calendars, CRM project milestones, and builder profiles. This enabled the AI agent to recognize and interpret PO and project IDs, SKUs, quantities, requested and expected dates, last change date, builder IDs, site ZIP, lane and lead time, backlog status, priority codes, and holidays.

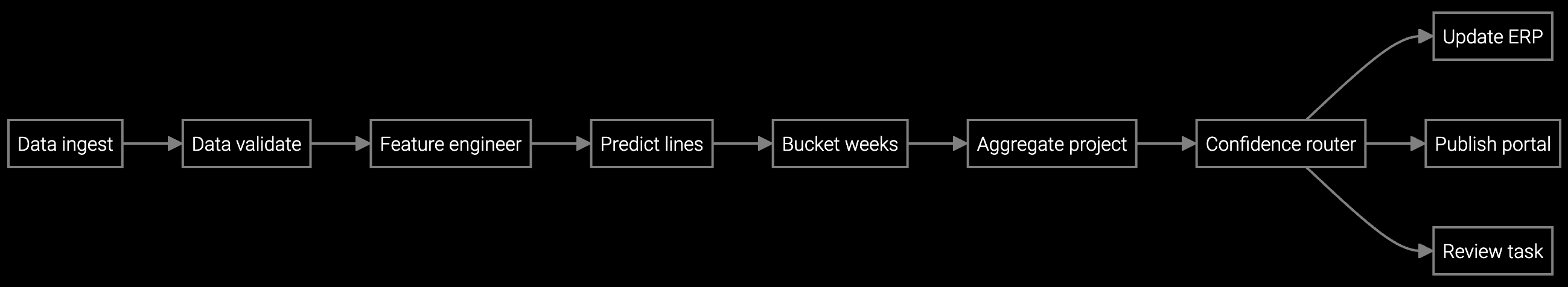

Workflow orchestration

The AI agent analyzes PO and project updates, extracts identifiers, and routes the right path: refresh features, run predictions, write back promise dates, publish project schedules, or open a review task. It navigates ERP, CRM, EDI portals, and shipping systems in the same sequence a supply chain planner would follow. Logic branches when confidence is below threshold, backlog holds exist, or lane times are missing, while enforcing policy and audit controls at each step.

Execution and resolution

The AI agent ingests and validates data, engineers features, trains and evaluates ensemble models, predicts per line with confidence scores, buckets results into weekly windows across 3–6 months, aggregates by project and SKU, updates promise dates, and notifies planners and customers. Responses complete in minutes, with updates posted across connected systems. Exceptions—such as conflicting change logs, sparse history for new SKUs, or missing carrier SLAs—are routed to planners with full context and what-if options for expedite or reallocation.