Predictive Maintenance Scheduling

Auto-recommend and book ≥60% of maintenance windows that reduce lost production minutes by ≥15% while keeping policy compliance ≥98% and fully updating MES, CMMS/EAM, ERP, and calendars.

Challenge

Semiconductor fabs run tools on tight production calendars where unplanned downtime is costly. Scheduling maintenance is manual, reactive, and fragmented across MES, CMMS/EAM, ERP, and workforce systems. Teams struggle to balance failure risk, lot priorities, technician skills, cleanroom rules, and parts availability. Predictive fault signals exist but are not integrated with production plans, causing misaligned service windows, schedule collisions, and excess lost production minutes.

The objective: auto-recommend and book ≥60% of maintenance windows that reduce lost production minutes by ≥15% while keeping policy compliance ≥98% and fully updating MES, CMMS/EAM, ERP, and calendars.

Solution: How AIP changed the operating model

Learning and setup

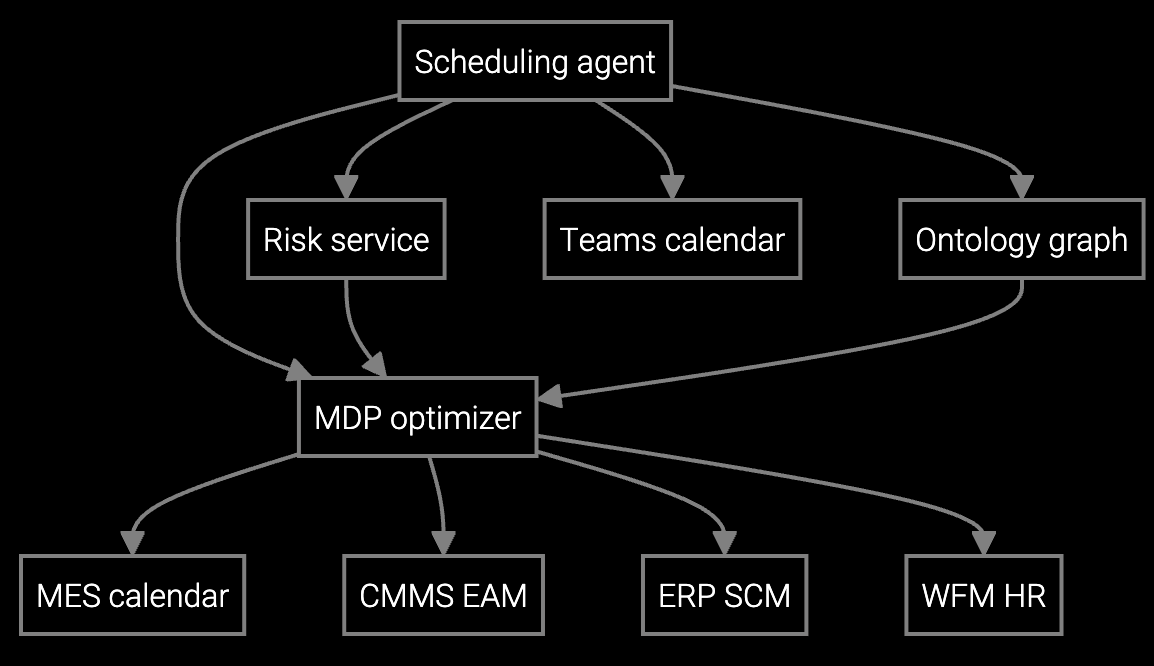

Powered by the Aftermarket Intelligence Platform AIP, the agentic solution applied its predictive risk, forecasting, policy MDP optimizer, and ontology-driven reasoning models. Training data came from IoT telemetry and health indicators, historical PM and CM logs and durations, production calendars and WIP from MES, technician rosters and certifications, shift schedules, parts inventory and lead times, SOPs and maintenance policies, prior schedule outcomes and impact metrics, plus annotated scheduling workflows and screens. This enabled the AI agent to recognize and interpret asset and tool IDs, tool family and model, risk scores and MTTF, PM and CM type, duration estimates, required parts and quantities, on hand and ATP levels, lead times, technician skills, shift and blackout windows, lot priorities, SLAs, cleanroom constraints, and cost rates.

Workflow orchestration

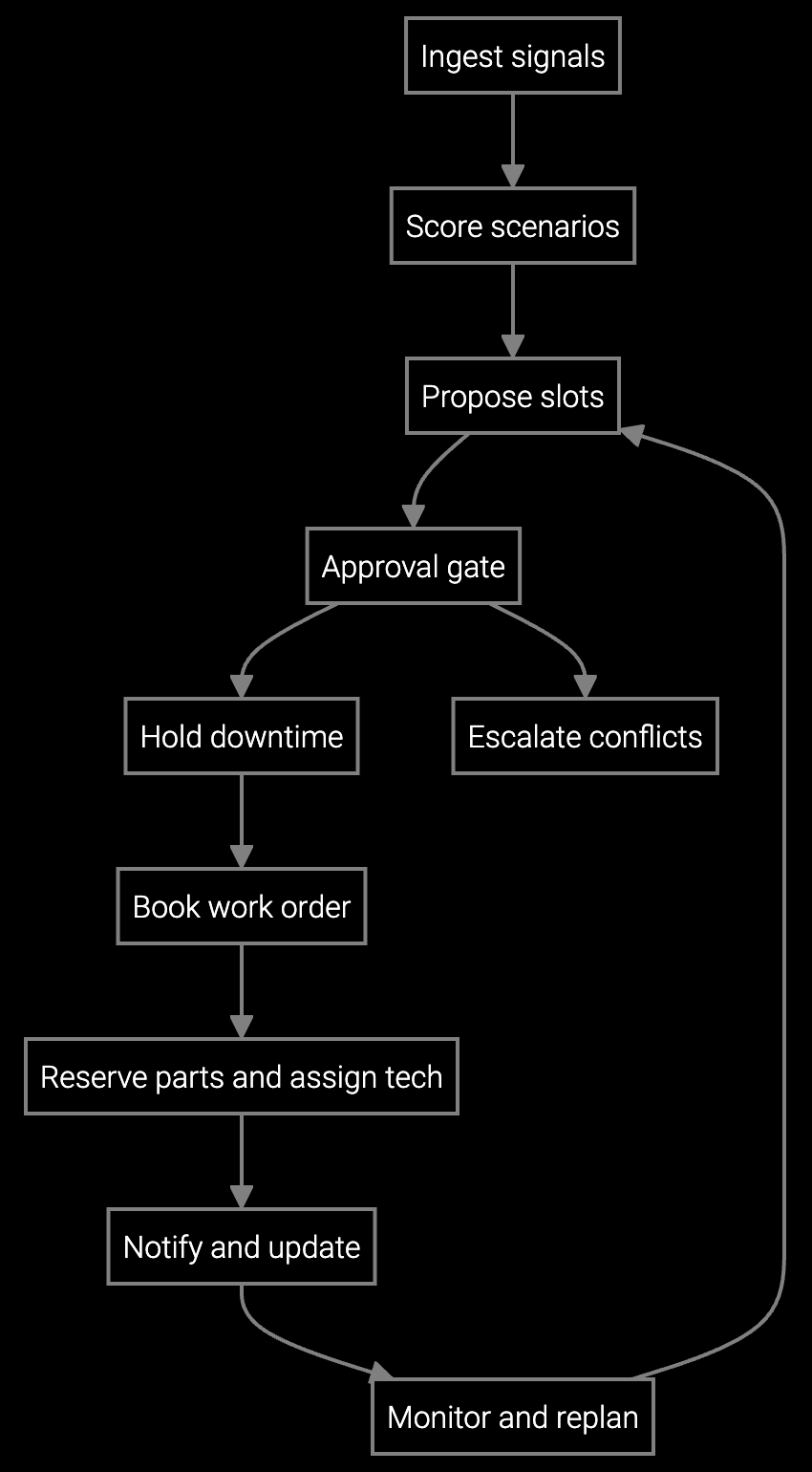

The AI agent reads incoming telemetry and MES calendars, extracts identifiers and constraints, and determines the correct path to hold downtime, verify entitlement, check parts, and plan labor. It navigates MES, CMMS and EAM, ERP and SCM, WFM and HR, and enterprise calendars to mirror how planners work. Logic branches on rules such as high priority lots, cleanroom blackout windows, missing certifications, or low parts ATP, while enforcing policy and capturing an audit trail. Approvals are requested when thresholds or SLAs are impacted; otherwise the system auto-books.

Execution and resolution

The AI agent generates what if scenarios, scores candidate windows by impact and risk, proposes slots, and auto-books approved selections. It creates work orders, reserves parts, assigns qualified technicians, sends invites, and posts updates across connected systems in minutes. The agent monitors lot moves, parts delays, and shift changes; when conditions change it re-plans and explains tradeoffs. Exceptions—such as parts back order, technician unavailability, or urgent lot priority changes—are routed to planners with full context and a recommended next best action.