Parts Identification from Blueprints

AI-powered blueprint analysis that auto-extracts technical specifications and mechanical parts from engineering drawings with 80% accuracy, standardizing cataloging across systems.

Challenge

Engineering teams manually review hundreds of drawings daily to extract dimensions, GD&T, materials, and identify components. Each drawing takes 15–20 minutes across CAD viewers, specification databases, PLM PDM, and ERP. Manual entry causes inconsistent metadata, missed tolerances, duplicate parts, and compliance risk.

The objective: Auto-extract ≥80% of technical specifications and mechanical parts from engineering drawings with accurate metadata capture and standardized cataloging across systems to further allow text+image based search.

Solution: How AIP changed the operating model

Learning and setup

Powered by the Aftermarket Intelligence Platform, the agentic solution applied OCR and computer vision models. Training data came from thousands of technical drawings, specification sheets, parts catalogs, and enterprise standards. This enabled the AI agent to recognize drawing templates, extract dimensions and tolerances, parse GD&T symbols, identify mechanical parts, and map metadata fields.

Workflow orchestration

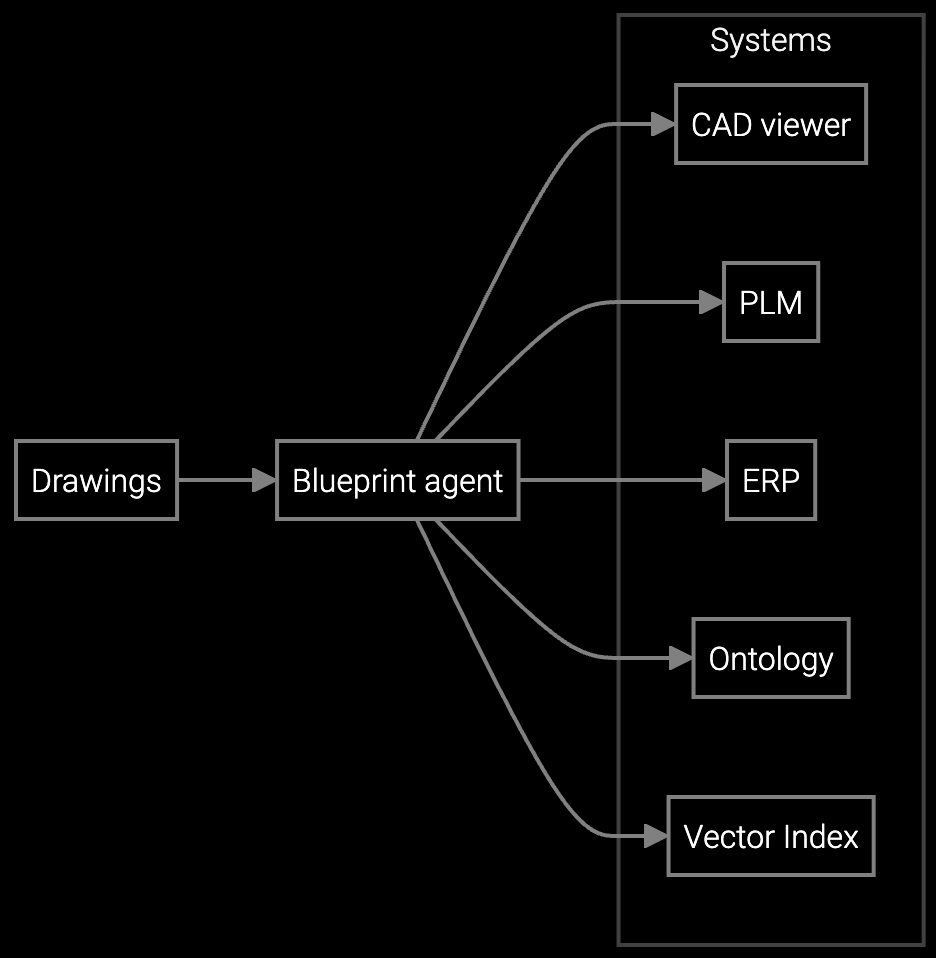

The AI agent reads new drawings, detects template types, and determines the correct path: detect tables and views, parse title blocks, extract dimensions with tolerances, parse GDT, and identify mechanical parts. It processes CAD drawings, PLM, ERP, the ontology, and a vector index for similarity search. Orchestration branches when rules apply, for example, when a drawing revision is superseded or when BOM and drawing data conflict, while ensuring ISO compliance and auditability.

Execution and resolution

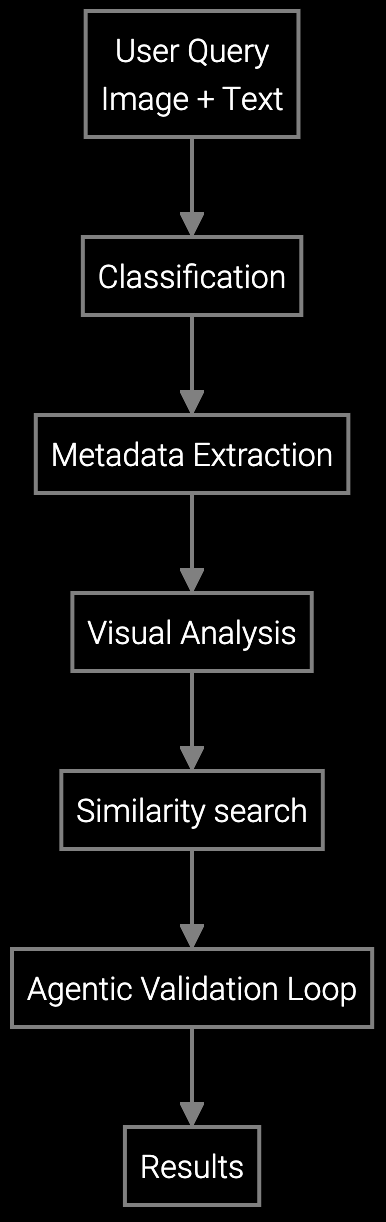

At inference time, based on input query with a part photo and description, the AI performs multi-modal similarity matching against all drawings and detected mechanical components, evaluating visual patterns, dimensions, tolerances, materials, and GD&T specifications. The system delivers re-ranked results in under 30 seconds with matched components highlighted and enables side-by-side comparison of multiple drawings to highlight dimensional differences and specification variations. Ambiguous matches are flagged with alternatives while the system continuously learns from user selections to improve search accuracy.