Digital Twin Quality Monitoring

AI-powered virtual sensor that predicts oil quality with 95% accuracy, eliminating manual TPM checks and optimizing oil change timing across all sites.

Challenge

Manual TPM checks require cooling, draining, and filtering oil, slowing kitchens and disrupting service. Physical inline sensors are costly to buy, install, calibrate, and replace, and they drift over time. Multi site operators switch between fryer UIs, maintenance apps, and spreadsheets to decide when to filter or discard oil, creating inconsistent decisions and compliance risk. Each round of checks can take 10–20 minutes per fryer per shift.

The objective: auto-predict ≥95% of oil quality readings, eliminate manual TPM checks, and forecast optimal oil change timing across all sites.

Solution: How AIP changed the operating model

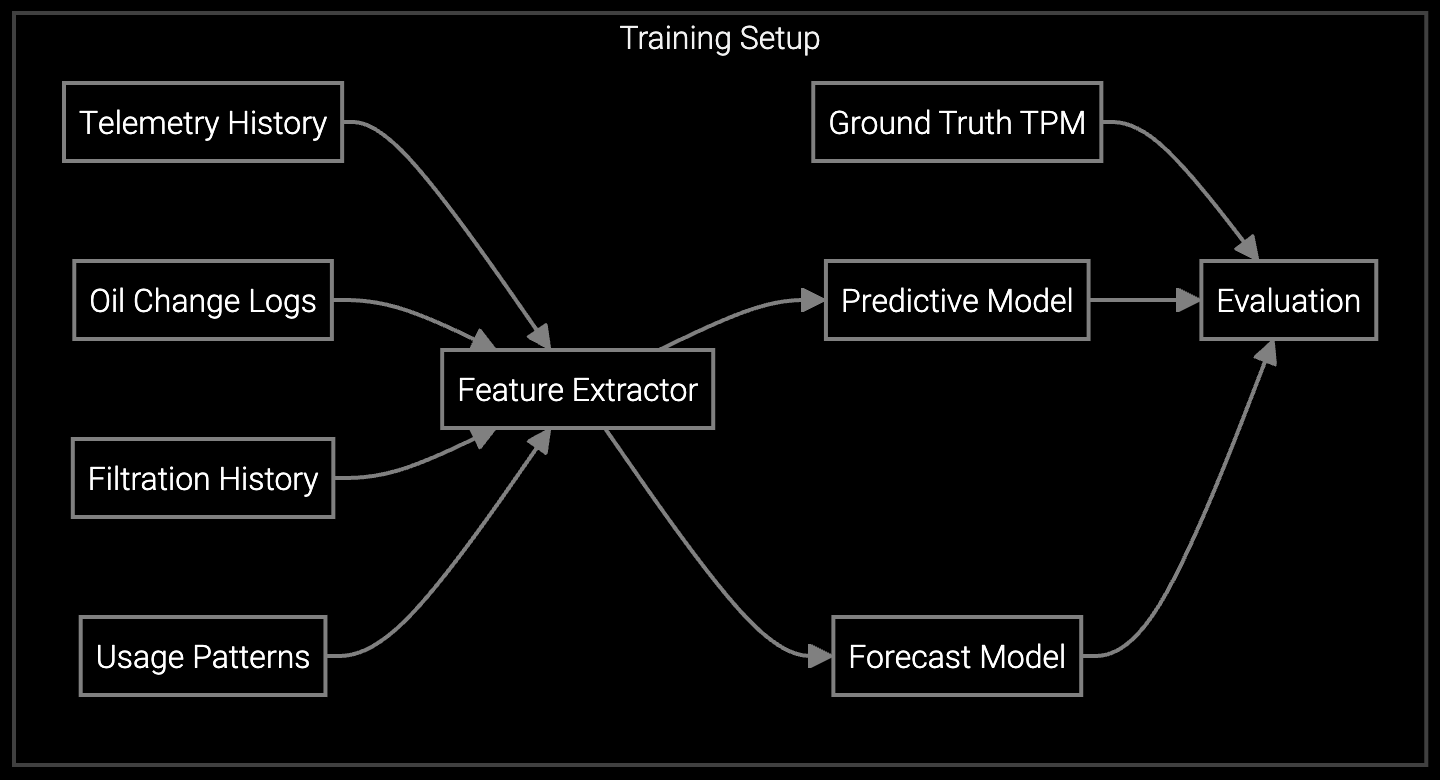

Learning and setup

Powered by the Aftermarket Intelligence Platform, the agentic solution applied predictive and forecasting models to create a virtual sensor and remaining life estimator. Training data came from 1,000+ connected fryers historical telemetry, oil change logs, filtration history, and usage patterns. The agent recognizes oil temperature, food type, fryer usage duration, filtration cycles, and oil age to estimate TPM and learn site specific behavior.

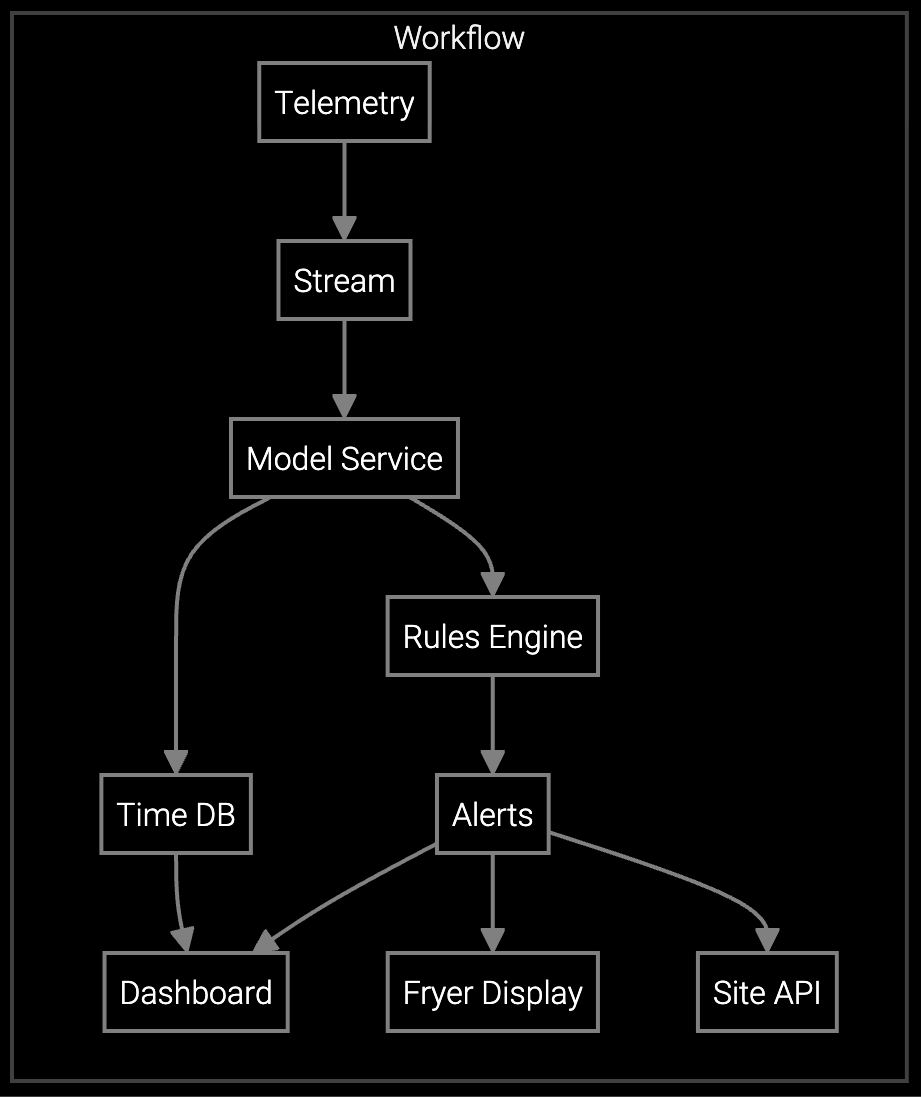

Workflow orchestration

The AI agent ingests real time telemetry, runs inference, stores predictions in a time series database, and synchronizes status across dashboards and fryer displays. It navigates device gateways, model services, rules, alerts, and APIs, mirroring how operations teams track oil health. Orchestration branches when thresholds or compliance windows apply, while drift checks and health monitors keep models accurate.

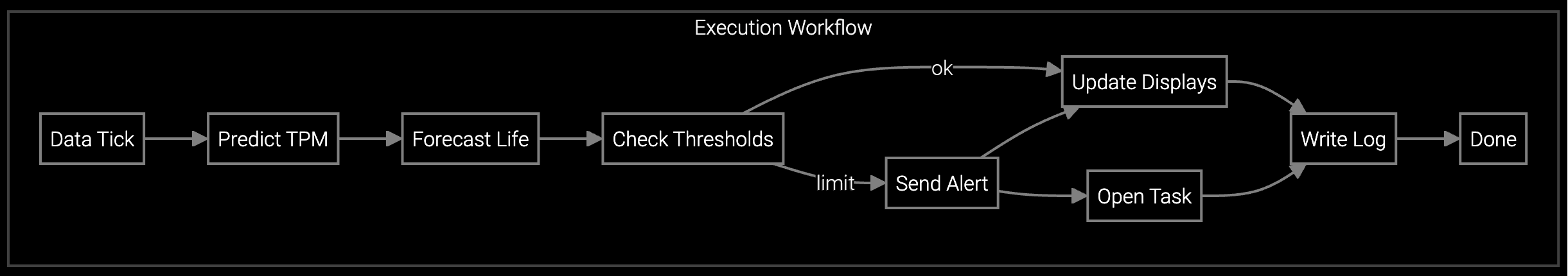

Execution and resolution

The agent continuously predicts current TPM, forecasts time to discard, triggers alerts at thresholds, recommends filter or change actions, writes compliant logs, updates fryer displays, and opens maintenance tasks when needed. Responses post in seconds across connected systems. Exceptions such as missing telemetry, signal drift, unusual temperature patterns, or offline devices are routed to staff with full context.