Real-Time Anomaly Detection

Detect and contextualize anomalies in under 2 seconds, reduce false positives by at least 50%, and cut unplanned downtime by at least 15% while maintaining 99.9% streaming availability.

Challenge

Fabs stream high frequency signals across pressure, flow, temperature, and vibration sensors on each tool. Manual monitoring is impossible, and static thresholds miss subtle multivariate drifts while creating alarm fatigue. Operators lose trust as false positives rise, and undetected anomalies drive scrap and costly downtime. Data is fragmented across historians, MES SCADA, and CMMS with limited context sharing.

The objective: detect and contextualize anomalies in under 2 seconds, reduce false positives by at least 50%, and cut unplanned downtime by at least 15% while maintaining 99.9% streaming availability.

Solution: How AIP changed the operating model

Learning and setup

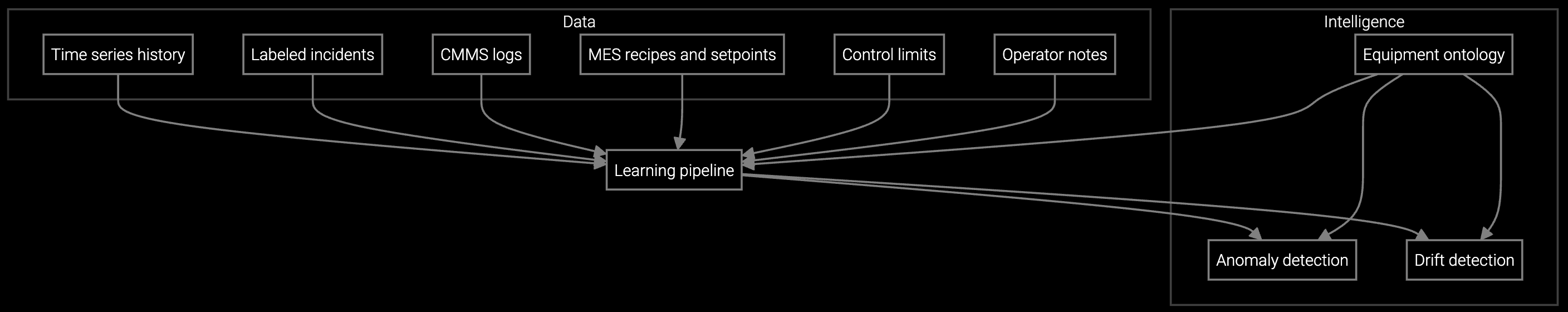

Powered by the Aftermarket Intelligence Platform AIP, the agentic solution applied its predictive anomaly detection, IoT telemetry, knowledge graph reasoning, and forecasting assisted drift models. Training data came from time series historians, labeled incidents and alarms, maintenance CMMS logs, MES recipes and setpoints, control limits and SOPs, operator annotations, and the equipment ontology. This enabled the AI agent to recognize sensor tags and units, timestamps, asset and tool ids, line and area, recipe and lot ids, setpoints and control limits, alarm codes, maintenance states, and shift context.

Workflow orchestration

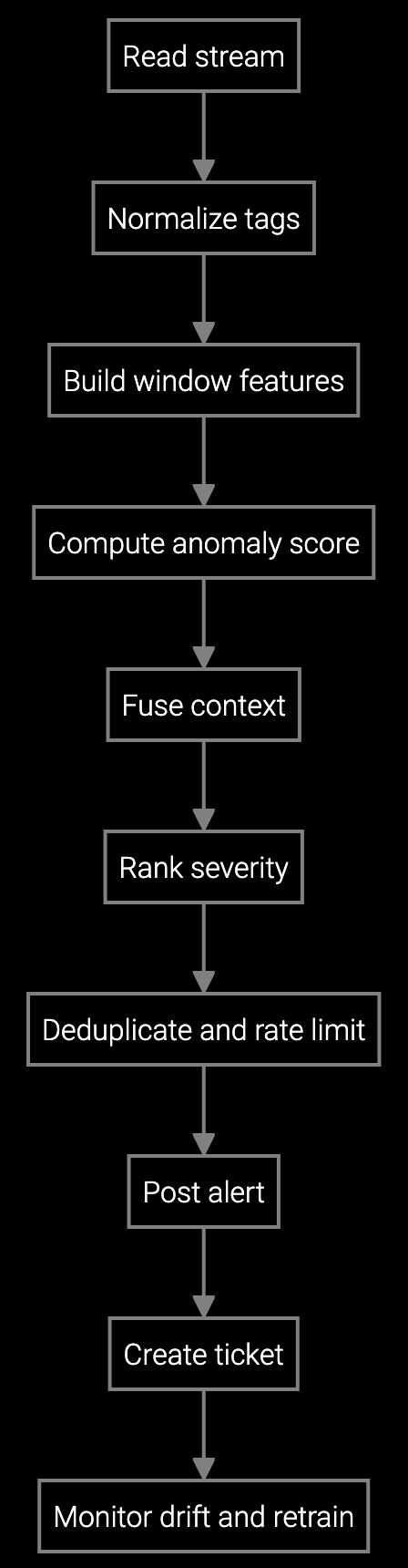

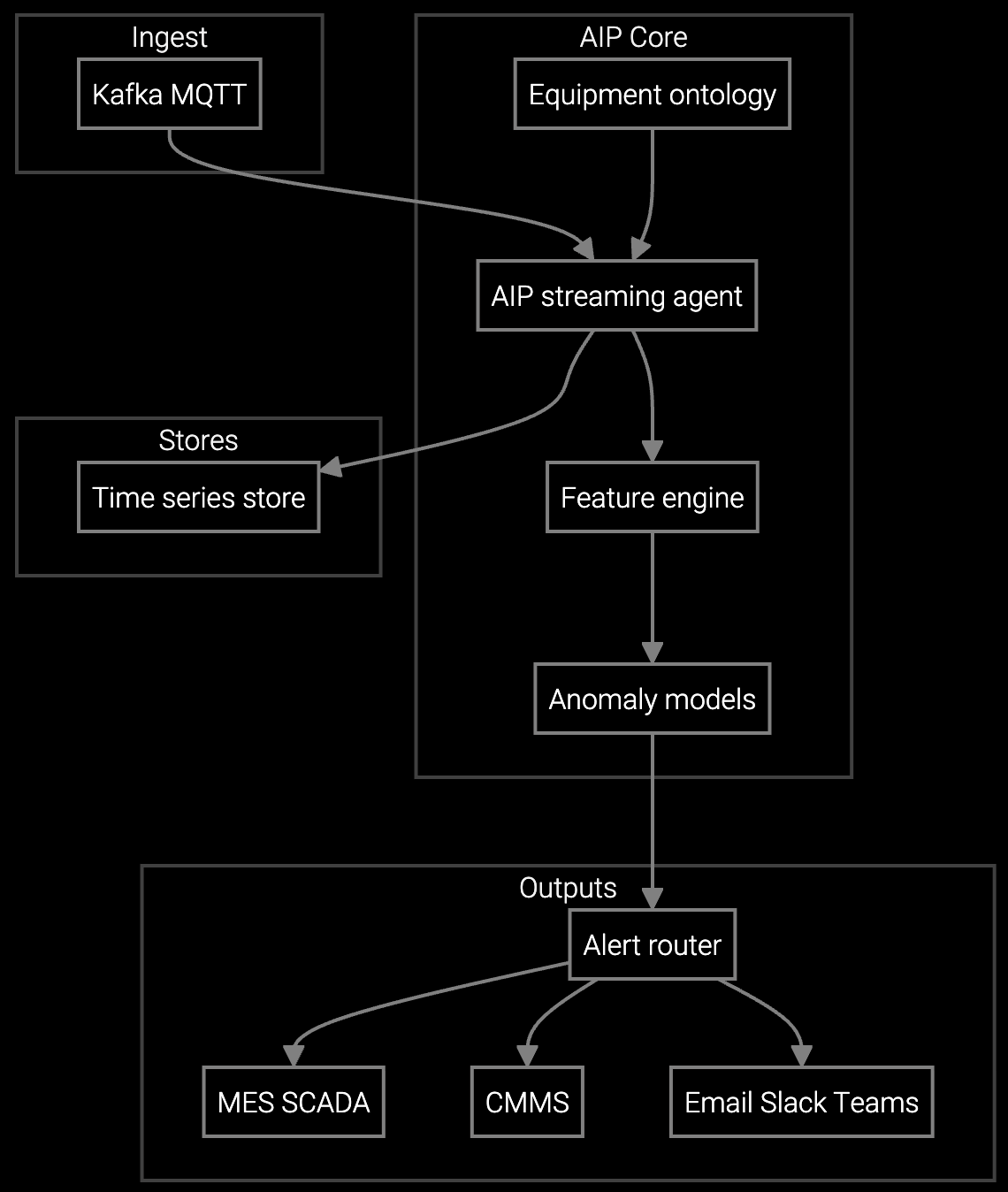

The AI agent reads streaming topics, extracts identifiers, and determines the correct path to compute features, score anomalies, and apply context. It navigates across Kafka MQTT, the ontology service, a time series store, and alert channels, mirroring the sequence a reliability engineer would follow. Orchestration logic branches when rules apply—for example, suppress during recipe change or an active maintenance state—while ensuring policy compliance for hold and notification actions.

Execution and resolution

The AI agent executes sliding window feature extraction, learns normal behavior with spectral clustering and isolation forests, and applies adaptive noise reduction with multivariate scoring. It fuses ontology context such as subsystem, recipe phase, and setpoint change to suppress benign deviations and rank severity. The agent deduplicates and rate limits alerts, posts actionable messages to MES SCADA, creates CMMS tickets with full context, and proposes likely root causes from similar cases. It monitors drift, auto retrains off shift, and versions models in the registry.