Field Service Parts Prediction

AI-powered parts recommendation system that predicts correct parts for service calls with 85% precision, reducing repeat truck rolls by 30%.

Challenge

Technicians often arrive without the right parts because symptoms and failure descriptions vary across manuals, legacy systems, and technician notes. Agents must navigate CRM FSM, ERP, and parts catalogs to interpret inconsistent terminology and compatibility rules. Each case takes 10–15 minutes and still misses supersession and entitlement nuances, driving repeat truck rolls, parts returns, expedited shipping, and low First-Time Fix Rate.

The objective: auto-recommend correct picklists for ≥70% of service calls with ≥85% precision, raise FTFR by ≥10 points, and cut repeat truck rolls by ≥30%, with compliant ERP FSM updates.

Solution: How AIP changed the operating model

Learning and setup

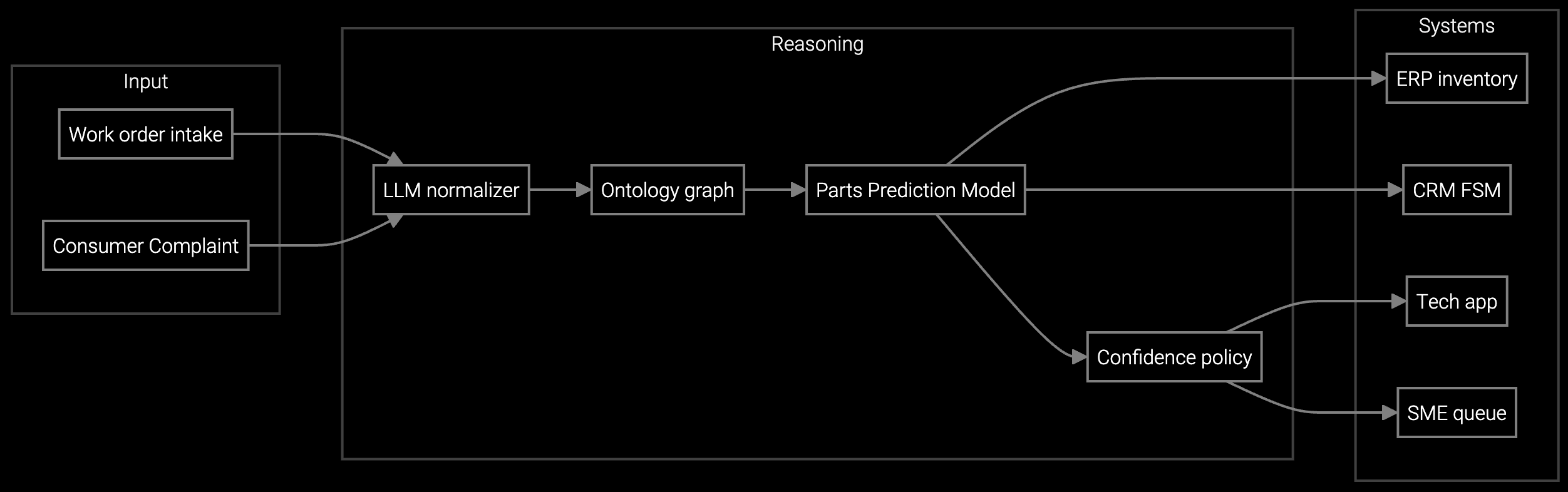

Powered by the Aftermarket Intelligence Platform (AIP), the agentic solution applied its parts prediction models, NLP LLM symptom normalizer, ontology graph reasoning, and policy confidence models. Training data came from historical work orders and parts usage, repeat-visit and returns data, OEM manuals and BOM and exploded views, technician notes and call transcripts, error-code dictionaries and IoT alerts, SKU supersession and compatibility tables, and warranty and entitlement rules. This enabled the AI agent to recognize and interpret equipment model and serial, install base attributes, free-text symptoms and failure codes, diagnostic codes, environment and usage hours, prior service history, part IDs and SKUs and supersessions, inventory across warehouses and trucks, location and time windows, and warranty status.

Workflow orchestration

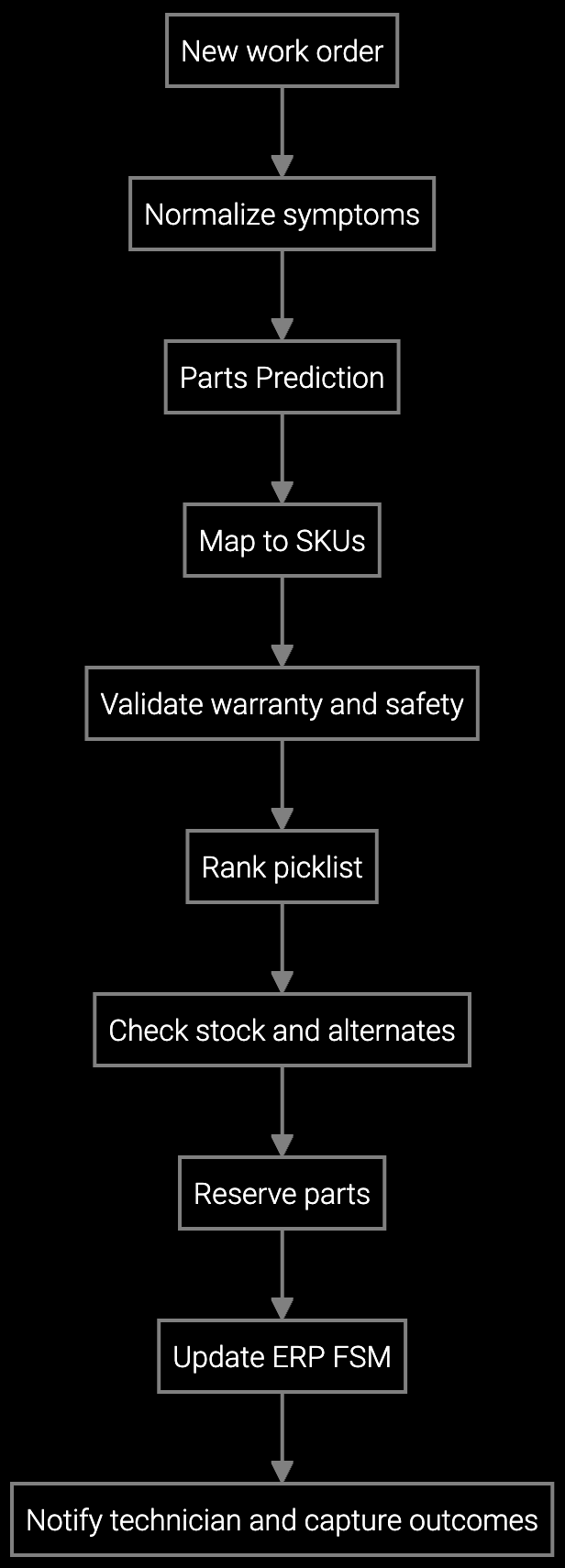

The AI agent reads work orders in CRM FSM such as Salesforce or ServiceNow or parses symptoms captured by call center agents in real time. It normalizes language with LLMs, queries the ontology to link equipment to symptoms to root causes to parts, then runs the Parts Prediction Model to rank candidate components. It checks ERP inventory for availability and lead times, applies policy gates for warranty and safety, creates reservations or POs, updates the work order, and publishes the picklist to the technician app. Branching occurs for low confidence, no stock, or discontinued SKU conditions, with compliant handling at every step.

Execution and resolution

The AI agent parses case context, normalizes terminology, infers likely failure components, maps to compatible SKUs with supersession rules, validates safety and warranty constraints, and generates a ranked picklist. Using system connectors, it checks stock across DCs and trucks, proposes alternates, reserves or ships parts, updates ERP FSM fields and notes, and notifies the technician. Responses complete in under two minutes. Exceptions such as ambiguous symptoms, no stock, mixed warranty status, or safety holds route to SMEs with full context and rationale.