Failure Pattern Recognition

Auto-detect ≥80% of recurring cross-system failure patterns and predict ≥70% of impending failures at least two hours in advance, reducing unplanned downtime by ≥30% with policy compliant updates to CMMS MES ERP.

Challenge

Operations teams sift through millions of log lines and high rate sensor streams scattered across historians, SCADA, MES, and technical notes. Patterns span pumps, chambers, and process steps, but the data sits in silos with inconsistent labels. Manual correlation takes hours and often misses hidden links such as vibration spikes that precede specific error codes. The consequence is reactive maintenance, recurring issues, and costly unplanned downtime.

The objective: auto detect ≥80% of recurring cross system failure patterns and predict ≥70% of impending failures at least two hours in advance, reducing unplanned downtime by ≥30% with policy compliant updates to CMMS MES ERP.

Solution: How AIP changed the operating model

Learning and setup

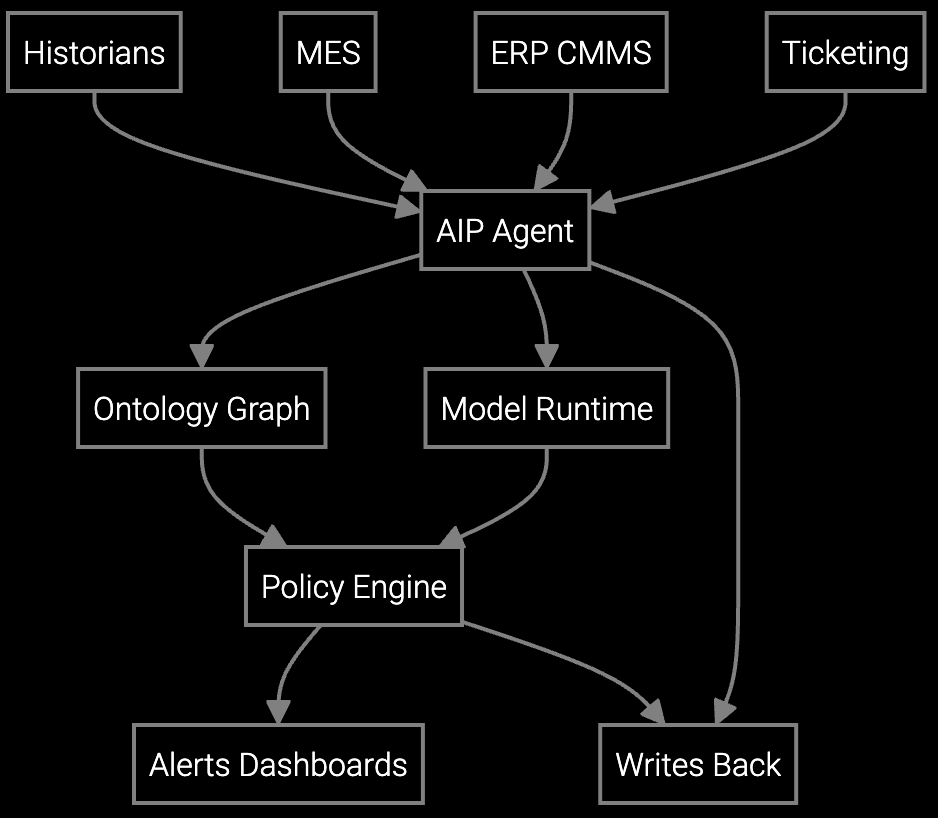

Powered by the Aftermarket Intelligence Platform (AIP), the agentic solution applied predictive analytics, anomaly detection, unsupervised clustering, sequence models, an ontology reasoner, a policy engine, and reinforcement learning for threshold tuning. Training data came from historical equipment logs, IoT telemetry for vibration temperature pressure flow and current, error code histories, maintenance and work orders, service tickets, technical notes and manuals, equipment hierarchy and BOM, labeled incidents and near misses, and operator annotations. This enabled the AI agent to recognize and interpret asset tool chamber and pump IDs, sensor tags and units, timestamps, error and failure codes, operating modes, process recipes and lots, location and line, maintenance actions and parts used, and warranty status.

Workflow orchestration

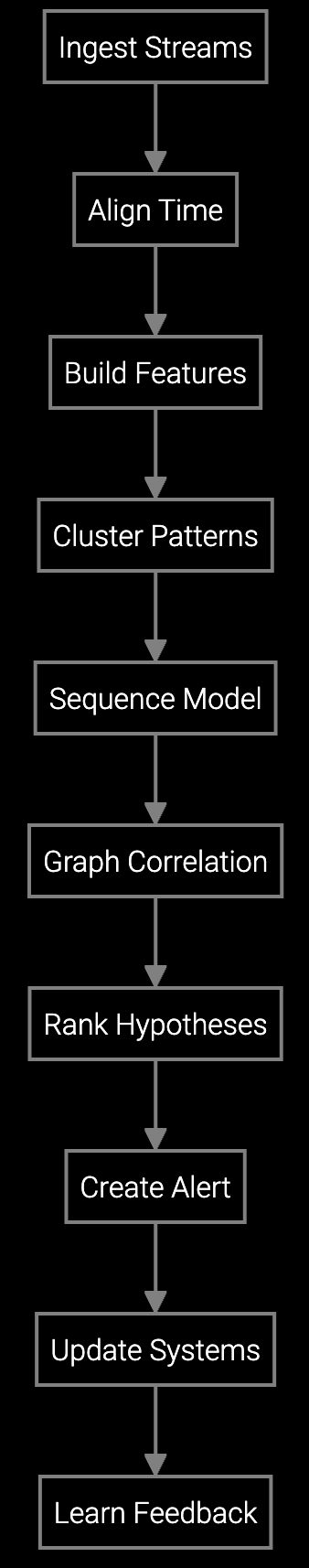

The AI agent reads incoming streams, aligns identifiers, and determines the correct path: detect anomalies, cluster signatures, predict failure precursors, correlate cross asset events, and generate recommended actions. It navigates across historians, SCADA, MES, ERP, CMMS, and ticketing, mirroring the sequence a reliability engineer would follow. Orchestration logic branches when rules apply—for example, if confidence exceeds the policy threshold the agent auto creates a work order and reserves parts; if confidence is moderate it schedules inspection; if warranty is active it routes to vendor while suppressing duplicate alerts.

Execution and resolution

The AI agent normalizes and aligns time series, builds FFT and spectrogram features, clusters signatures such as HDBSCAN, runs sequence models to detect early precursors, correlates cross asset events through the knowledge graph, ranks root cause hypotheses, and issues policy compliant actions. Responses complete in minutes, with updates posted to MES, CMMS, ERP, and dashboards. Exceptions—such as missing tags, clock drift, sensor dropouts, or unknown asset IDs—are routed to engineers with full context and evidence. The agent learns from technician feedback using reinforcement learning to refine thresholds and routing.