Remaining Useful Life Prediction

Predict component-level RUL for heaters, pumps, and bearings with ≤10% MAPE on critical assets; deliver ≥80% early warnings ≥7 days ahead; auto-create ≥70% proactive work orders with parts preallocated and policy-compliant updates across systems.

Challenge

High-value tools rely on calendar-based maintenance that ignores real operating stress. Teams face premature replacements or surprise failures. Telemetry lives in historians and PLCs, while maintenance and parts data sit in CMMS and ERP, creating silos. Analysts spend hours extracting signals without consistent, component-level forecasts. Unplanned downtime drives rush parts, overtime, and missed production targets.

The objective: predict component-level RUL for heaters, pumps, and bearings with ≤10% MAPE on critical assets; deliver ≥80% early warnings ≥7 days ahead; auto-create ≥70% proactive work orders with parts preallocated and policy-compliant updates across systems.

Solution: How AIP changed the operating model

Learning and setup

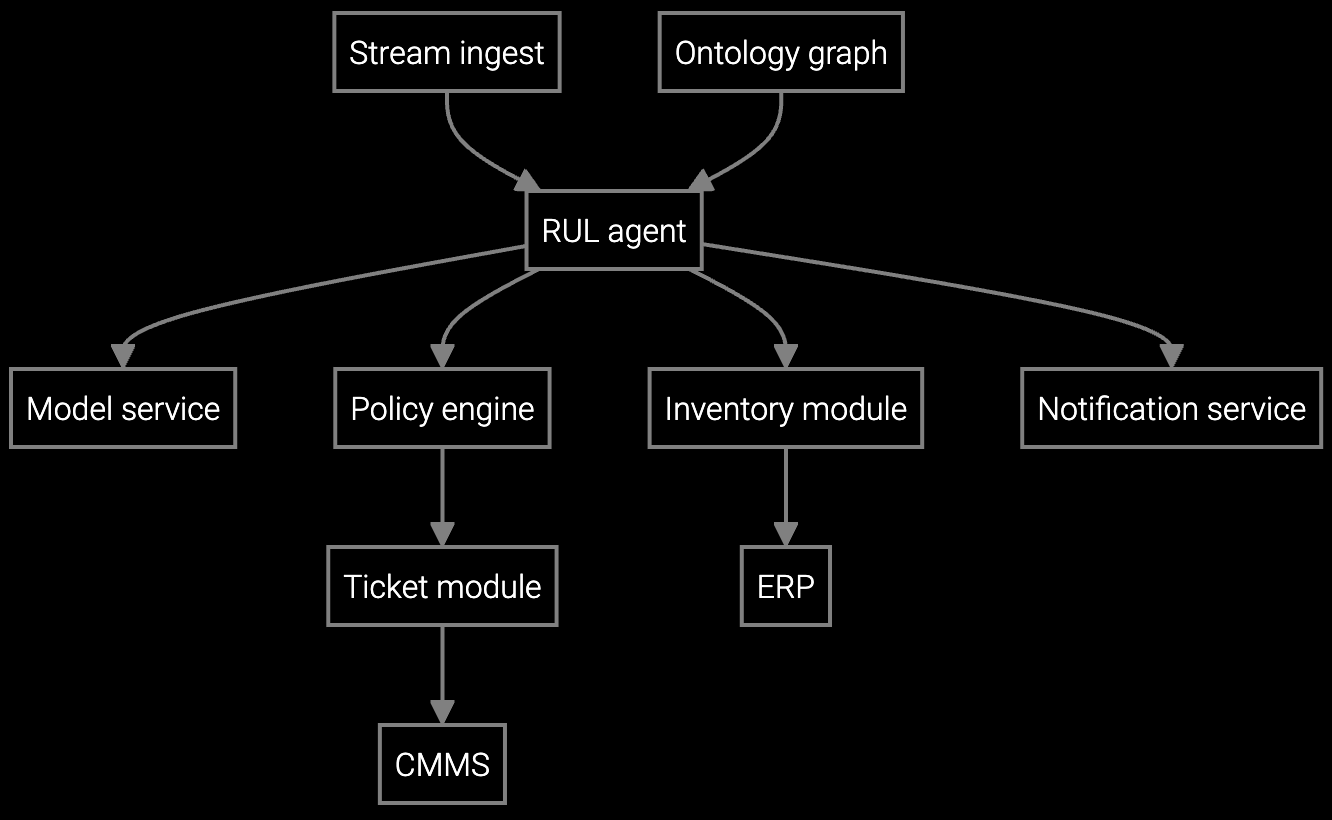

Powered by the Aftermarket Intelligence Platform AIP, the agentic solution applied its predictive, forecasting, and policy models including LSTM and temporal CNNs, survival analysis, gradient boosting, and anomaly detection governed by a policy engine. Training data came from IoT and SCADA historians, PLC telemetry, duty-cycle metrics, process setpoints, ambient sensors, CMMS and EAM work orders with failure labels, parts replacement history, supplier life curves, FMEA notes, and the equipment ontology. This enabled the AI agent to recognize and interpret asset and component IDs, serial and model, timestamps, sensor tags like temperature, vibration, current, pressure, flow, run-hours, duty cycle, alarms and fault codes, maintenance events, part numbers, warranty terms, and location context.

Workflow orchestration

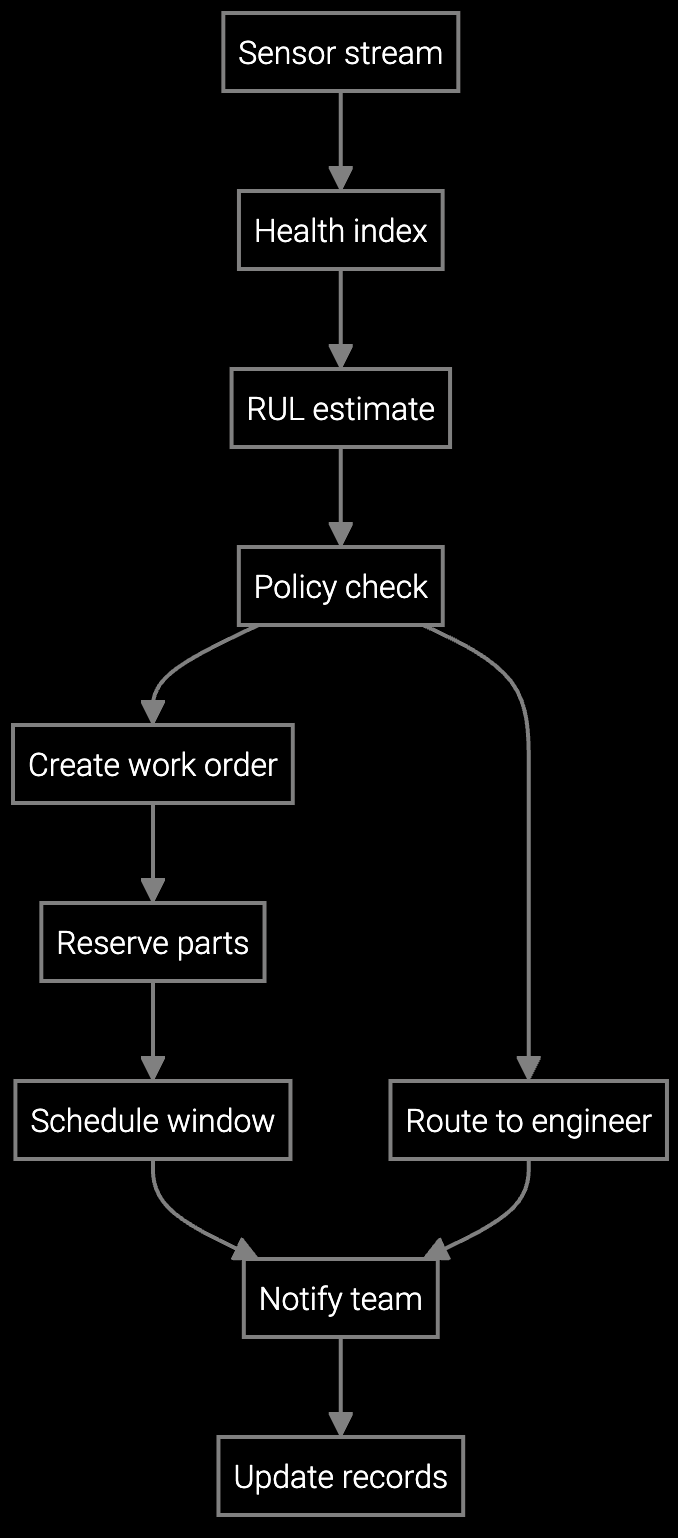

The AI agent reads streaming telemetry, fuses context from Equipment, Asset Management, Ticket Workflow, and Inventory modules, and routes actions. It computes health indices, estimates RUL, and applies policy rules to determine next steps such as open work order, reserve parts, propose a maintenance window, or notify teams. Branching covers lead time risk, warranty coverage, and SLA priority to ensure compliance at every step.

Execution and resolution

The AI agent cleans and featurizes signals, runs online inference to compute health indices and RUL, calibrates thresholds by component class and SLA, then executes: create work order, reserve parts for just in time replacement, update calendars, and send targeted alerts. Responses complete in seconds, with updates posted across connected systems. Exceptions like sensor drift, missing tag mappings, or low confidence cases route to engineering with full context attached.