Defect Source Tracing

Auto-attribute ≥75% of defect excursions to a specific tool lot step within 2 hours, cut false quarantines by ≥40%, and generate ranked corrective actions with compliant updates across MES, QMS, and EAM.

Challenge

Fabs must trace defects to specific sources across siloed systems including MES, SPC, tool logs, LIMS, CMMS, and inspection images. Engineers manually stitch evidence across chambers, shifts, and material batches, with limited cross layer traceability. Contamination prone assets like vertical furnaces are frequent hotspots. Each excursion consumes 6–12 hours of engineering time and often triggers broad quarantines, scrap, and lost yield.

The objective: auto attribute ≥75% of defect excursions to a specific tool lot step within 2 hours, cut false quarantines by ≥40 percent, and generate ranked corrective actions with compliant updates across MES, QMS, and EAM.

Solution: How AIP changed the operating model

Learning and setup

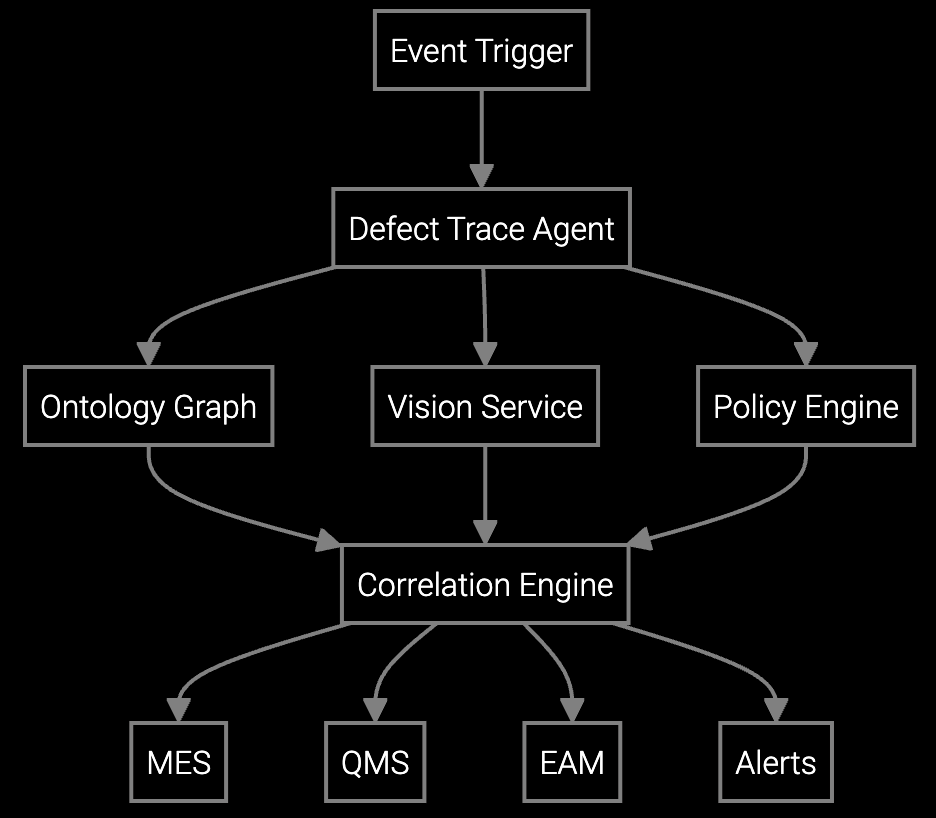

Powered by the Aftermarket Intelligence Platform (AIP), the agentic solution applied ontology and graph reasoning, graph ML with causal ranking, vision models for AOI SEM and wafer maps, predictive anomaly detection, and a policy engine for containment and CAPA rules. Training data came from MES lot and wafer history, tool and chamber logs and alarms, SPC charts, process recipes and revisions, inline inspection and FA images, electrical test and yield, contamination LIMS data, CMMS and EAM service and parts history, operator rosters, and past RCA reports. This enabled the AI agent to recognize and interpret lot_id, wafer_id, tool_id, chamber_id, op_code, recipe_id and version, timestamps, shift_code, material_batch, defect classes and wafer maps, telemetry, alarm codes, maintenance tickets, and contamination metrics.

Workflow orchestration

The AI agent analyzes events such as yield hits, SPC violations, and inspection fails, extracts identifiers, and selects the path to vision checks, anomaly correlation, and causal ranking. It federates data via the ontology and navigates MES, SPC, LIMS, CMMS, and EAM, mirroring the sequence engineers follow. Orchestration branches when ties occur across tools or chambers within a confidence margin, invoking additional evidence tests while enforcing containment and CAPA policies.

Execution and resolution

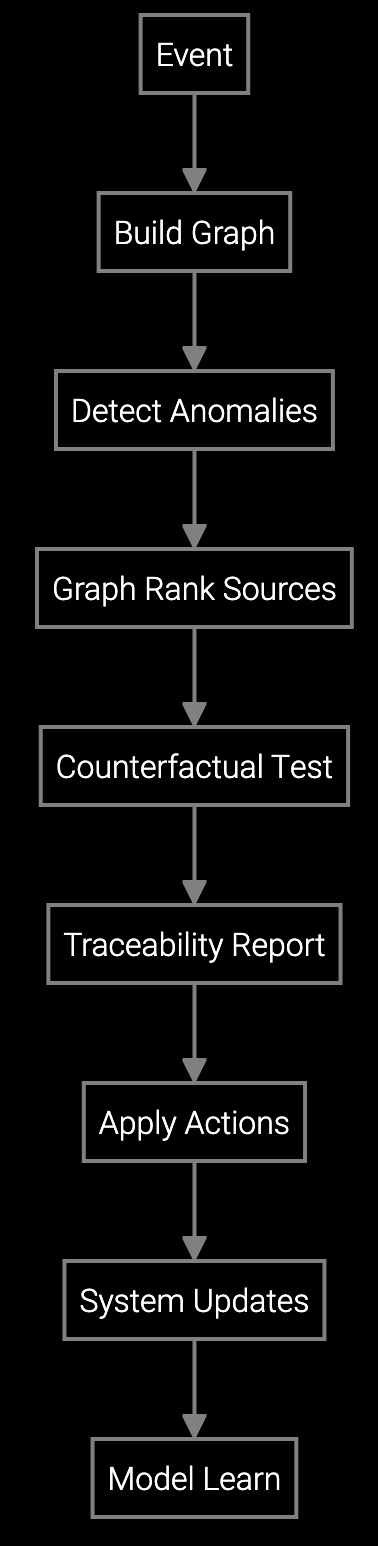

The AI agent builds and enriches the knowledge graph, detects anomaly signatures by wafer lot and tool, runs graph traversal with causal scoring to rank likely sources, validates with counterfactual tests, and composes traceability reports with evidence. Actions are recommended and applied such as recipe tweak, chamber clean, part swap, lot rework, or targeted holds. Responses complete in minutes to under two hours with updates written to MES, QMS, and EAM. Exceptions like mixed defect classes, missing telemetry, or conflicting tool matches are routed to engineers with full context.