Equipment lifecycles spanning decades demand systems built to evolve, not expire in three years.

Industrial OEMs choose hybrid approaches: buy foundational asset tracking and configuration management platforms, then customize with APIs for unique workflows. This reduces deployment time from 18+ months to 3-6 months while maintaining flexibility for proprietary processes and legacy system integration.

Custom-built systems require 18-24 months before going live. During that time, configuration drift continues and asset data quality degrades further.

Industrial equipment deployed over 10-30 year spans means connecting to PLCs, SCADA systems, and databases using protocols from multiple decades.

Homegrown systems become technical debt as internal developers move on and documentation falls behind. Maintenance consumes resources that should drive innovation.

Bruviti's platform delivers foundational asset registry and configuration management capabilities out-of-the-box while exposing APIs for custom workflows. This means your team focuses on differentiating logic—upgrade path rules, EOL transition processes, contract attachment workflows—instead of building CRUD interfaces and database schemas.

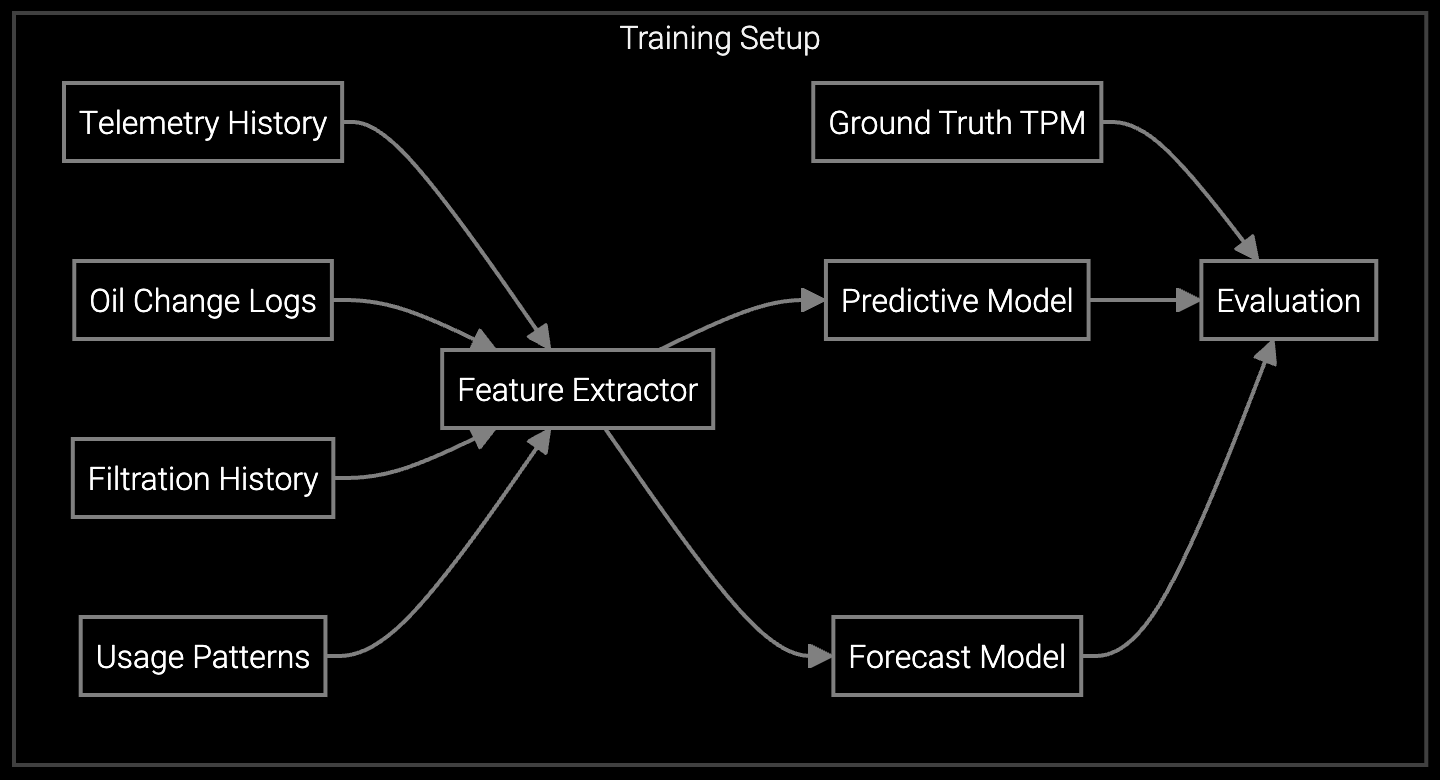

The platform handles sensor data ingestion from PLCs and SCADA systems regardless of protocol age. It manages serial number tracking, firmware version monitoring, and configuration drift detection without custom code. Your developers extend these foundations through APIs to address industry-specific needs like tooling configuration for CNC equipment or pressure sensor telemetry for compressor fleets.

Track CNC machine tool performance through virtual models that mirror deployed equipment behavior and predict maintenance windows.

Estimate compressor bearing life based on vibration patterns and run hours to schedule replacements during planned downtime.

Move from time-based to condition-based maintenance schedules using real equipment telemetry and usage patterns.

Industrial equipment OEMs face unique challenges that generic asset tracking systems ignore. Equipment deployed in 1995 still runs production lines. Those systems use Modbus over serial connections, not REST APIs. Configuration data lives in paper binders at customer sites, not centralized databases.

A hybrid platform approach addresses these realities. Core capabilities like serial number registry and configuration versioning deploy immediately. Meanwhile, your team builds custom adapters for legacy protocols and develops industry-specific rules for EOL transitions. This parallelism cuts time-to-value by 60% compared to ground-up builds.

Platform deployment averages 3-6 months from contract to production use. This includes data migration from legacy systems, integration with ERP and service management tools, and configuration of asset tracking workflows. Custom builds typically require 18-24 months before going live because teams must design schemas, build interfaces, implement integrations, and conduct extensive testing.

Yes. Industrial OEMs commonly need to connect equipment using Modbus, PROFIBUS, and older SCADA protocols. The platform includes protocol adapters for common industrial standards and exposes APIs to build custom adapters for proprietary systems. This hybrid approach handles both modern IoT sensors and decades-old PLCs within the same asset registry.

The API-first architecture means your custom workflows and integrations remain portable. All asset data, configuration history, and telemetry records export through standard APIs. Many OEMs start with core platform features then gradually move certain capabilities in-house as teams mature, using the platform as a foundation rather than a black box.

Start by importing whatever records exist from warranty systems, ERP databases, and service history. The platform flags gaps in serial numbers, configurations, and firmware versions. Then run targeted data enrichment campaigns—QR code scanning at service visits, customer self-registration portals, or manual audits of high-value assets. Asset data accuracy typically improves from 60% to 90% within 90 days using these methods.

Most industrial OEMs see measurable returns within 6-9 months. Early wins come from improved contract renewal rates as accurate asset visibility enables proactive outreach before expirations. Subsequent gains include reduced configuration-related service calls and better upsell targeting based on equipment age and usage patterns. Full ROI including predictive maintenance benefits typically arrives within 18-24 months.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how Bruviti reduces deployment time while maintaining strategic flexibility.

Schedule Strategy Session