Accurate asset data drives uptime commitments—but manual tracking can't scale across thousands of deployed devices.

Network OEMs face a strategic choice: build custom asset tracking systems requiring ongoing engineering resources, or deploy AI-powered platforms that automatically sync configuration data, detect drift, and maintain accurate installed base records without manual updates.

Missing serial numbers and configuration details prevent proactive maintenance. Network operations teams can't predict failures or plan upgrades when asset records lack firmware versions, deployment dates, or usage patterns.

Actual device configurations diverge from records as customers make changes. This gap creates risk during troubleshooting and prevents accurate assessment of security vulnerabilities across the deployed base.

Without visibility into upcoming EOL dates and contract expirations, renewal opportunities slip through. Sales teams lack the asset intelligence needed to drive timely upgrade conversations with customers.

Building custom asset tracking requires dedicated engineering teams to develop integrations with SNMP monitoring, syslog aggregation, and customer registration portals. This approach offers full control but demands continuous maintenance as device portfolios expand and protocols evolve. The typical build timeline spans 18-24 months before production deployment.

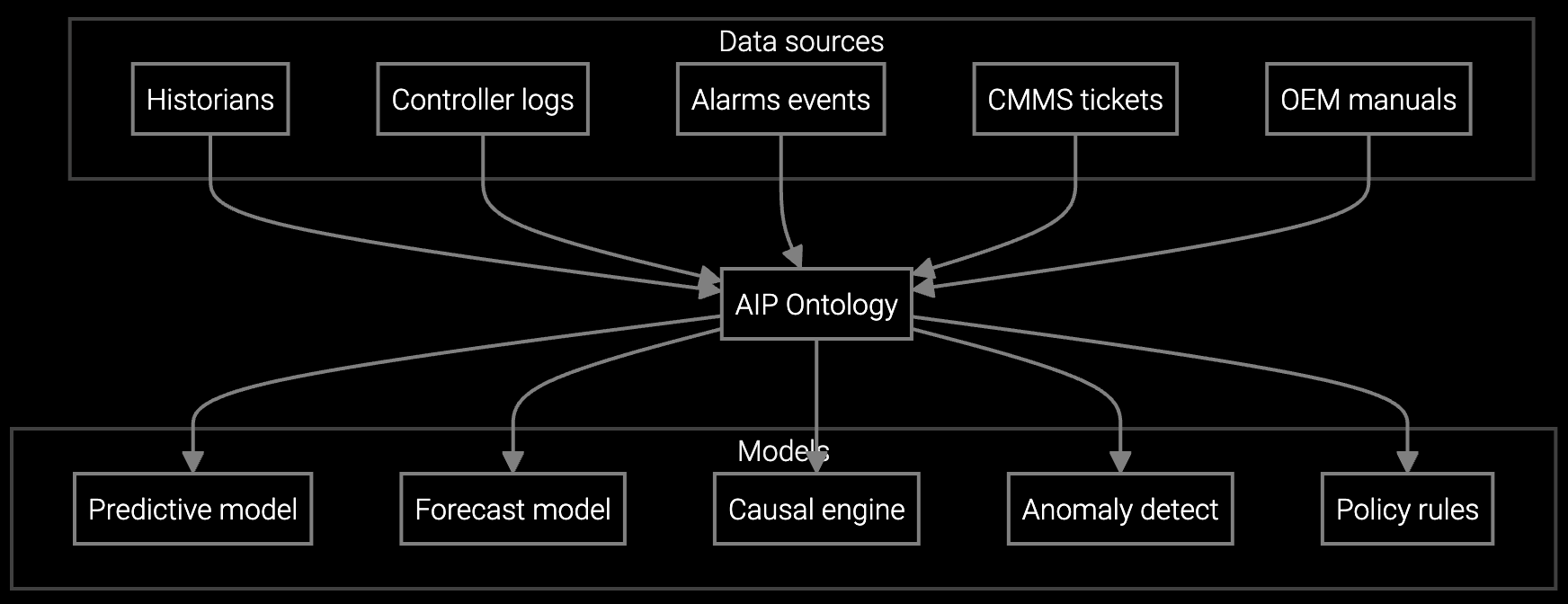

AI-powered platforms eliminate this engineering overhead by automatically ingesting telemetry from network devices, detecting configuration changes through log analysis, and maintaining synchronized asset records. The platform continuously reconciles data from multiple sources—customer portals, NOC monitoring systems, and field service records—to provide a single accurate view without manual data entry.

Analyzes SNMP traps and syslog streams from routers and switches to identify anomalies signaling imminent failures across network infrastructure.

Estimates when optical transceivers and power supplies will fail based on usage telemetry, enabling planned maintenance during scheduled windows.

Schedules firmware updates and component replacements based on actual device condition rather than fixed intervals, reducing unnecessary maintenance events.

Network OEMs manage installed bases spanning enterprise switches, carrier routers, and wireless access points deployed across distributed locations. These devices generate continuous telemetry through SNMP polling and syslog forwarding, but this data often sits in customer NOCs rather than OEM asset databases.

Five nines availability requirements make proactive asset intelligence critical. When a core router fails, customers expect OEMs to rapidly identify the configuration, firmware version, and replacement parts without extended discovery processes. Building systems to maintain this intelligence competes with core product development priorities.

Platforms automatically ingest telemetry from network devices via SNMP, parse syslog streams for configuration changes, and reconcile registration portal data with field service records. Machine learning models detect anomalies between sources and flag inconsistencies for automated resolution, eliminating swivel-chair data entry across multiple systems.

Network OEMs typically see positive ROI within 6-9 months through reduced RMA processing costs, improved contract renewal rates, and decreased engineering maintenance burden. The platform eliminates ongoing development costs for custom integrations while accelerating deployment compared to 18-24 month build cycles.

The platform continuously analyzes syslog messages and SNMP polling data to detect when actual device configurations diverge from recorded baselines. It identifies firmware changes, interface modifications, and routing updates as they occur, automatically updating asset records and alerting teams when changes introduce security vulnerabilities or support risks.

Yes, the platform connects to standard network monitoring systems through SNMP integration, syslog forwarding, and API connections. It augments existing NOC tools by adding predictive analytics and automated asset reconciliation without requiring customers to change their monitoring infrastructure.

Operational teams use the platform through a single interface requiring no specialized AI expertise. The system handles data reconciliation, anomaly detection, and predictive modeling automatically. Your team focuses on reviewing insights and taking action rather than building and maintaining machine learning pipelines.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how AI-powered platforms eliminate manual tracking while maintaining accurate installed base intelligence.

Schedule Strategy Discussion