Legacy equipment drives high case volumes—decide which AI approach delivers faster resolution without disrupting operations.

Industrial manufacturers should adopt hybrid AI platforms that integrate with existing CRM systems, train on historical case data, and deploy incrementally by product line. This balances customization needs with speed to value while maintaining operational continuity.

Long equipment lifecycles mean agents field questions spanning 30 years of models with varying documentation quality. Knowledge retrieval slows as product lines expand and legacy systems remain in operation.

Contact centers struggle with agent turnover and training time while case volumes grow. New hires need months to handle complex equipment inquiries across diverse installed bases.

Different agents provide varying answers to the same questions about repair procedures, warranty coverage, and parts availability. This erodes customer confidence and increases repeat contacts.

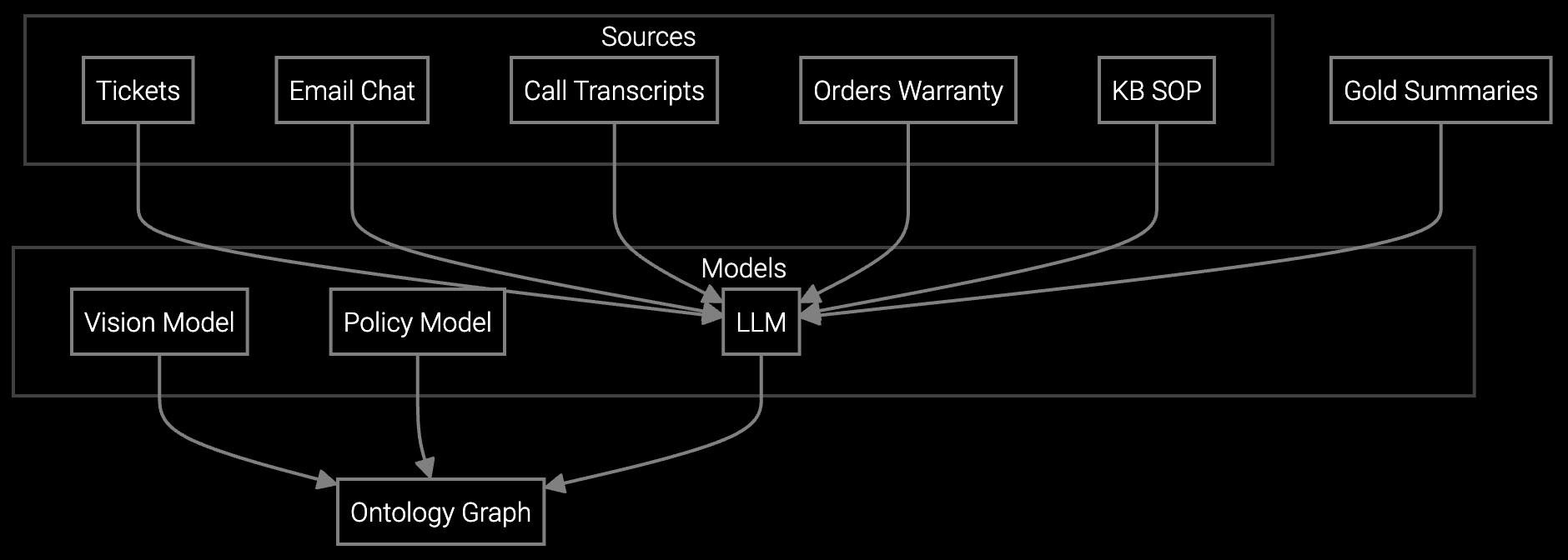

The choice between building internal AI capabilities and buying a platform creates a false dilemma. Industrial manufacturers need both control and speed. Bruviti's hybrid approach integrates with existing ticketing systems while training models on your historical case data, equipment manuals, and repair histories. This delivers pre-built automation for common workflows while preserving flexibility to customize for specialized equipment lines.

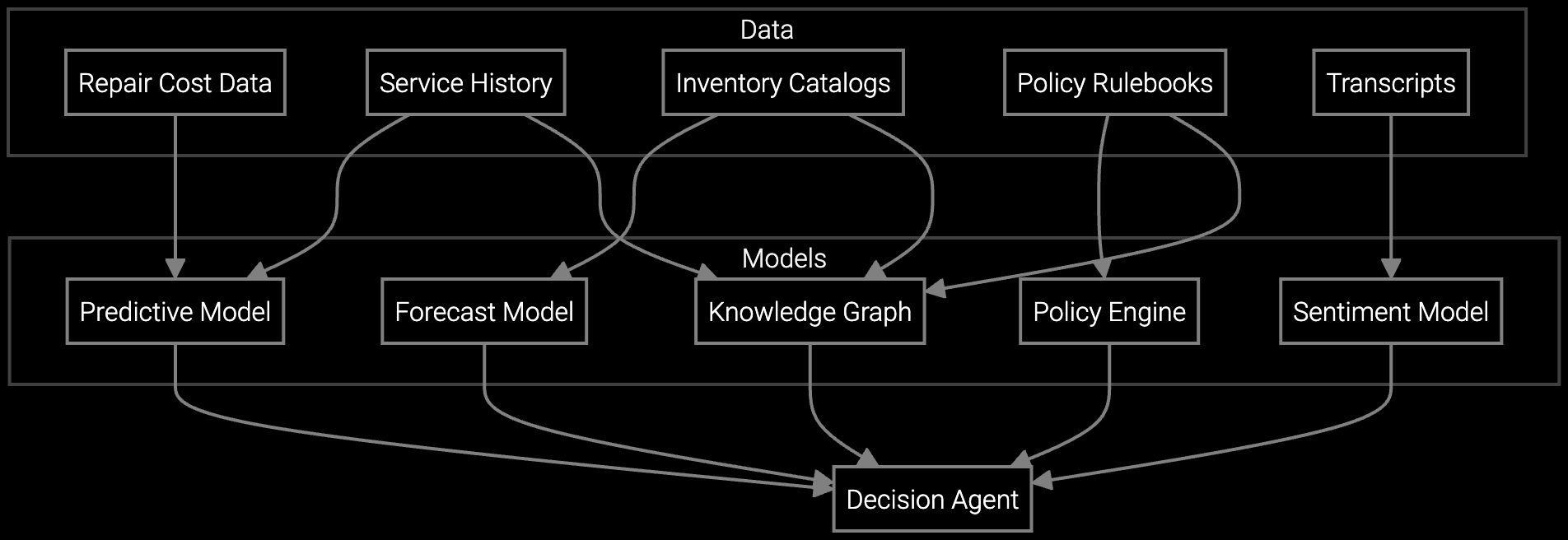

Deploy incrementally by starting with high-volume case types like parts identification or warranty validation, then expand to complex troubleshooting. This phased rollout minimizes disruption while proving ROI before broader commitment. Your team controls which workflows to automate and which require human oversight, avoiding the all-or-nothing risk of custom builds or rigid vendor solutions.

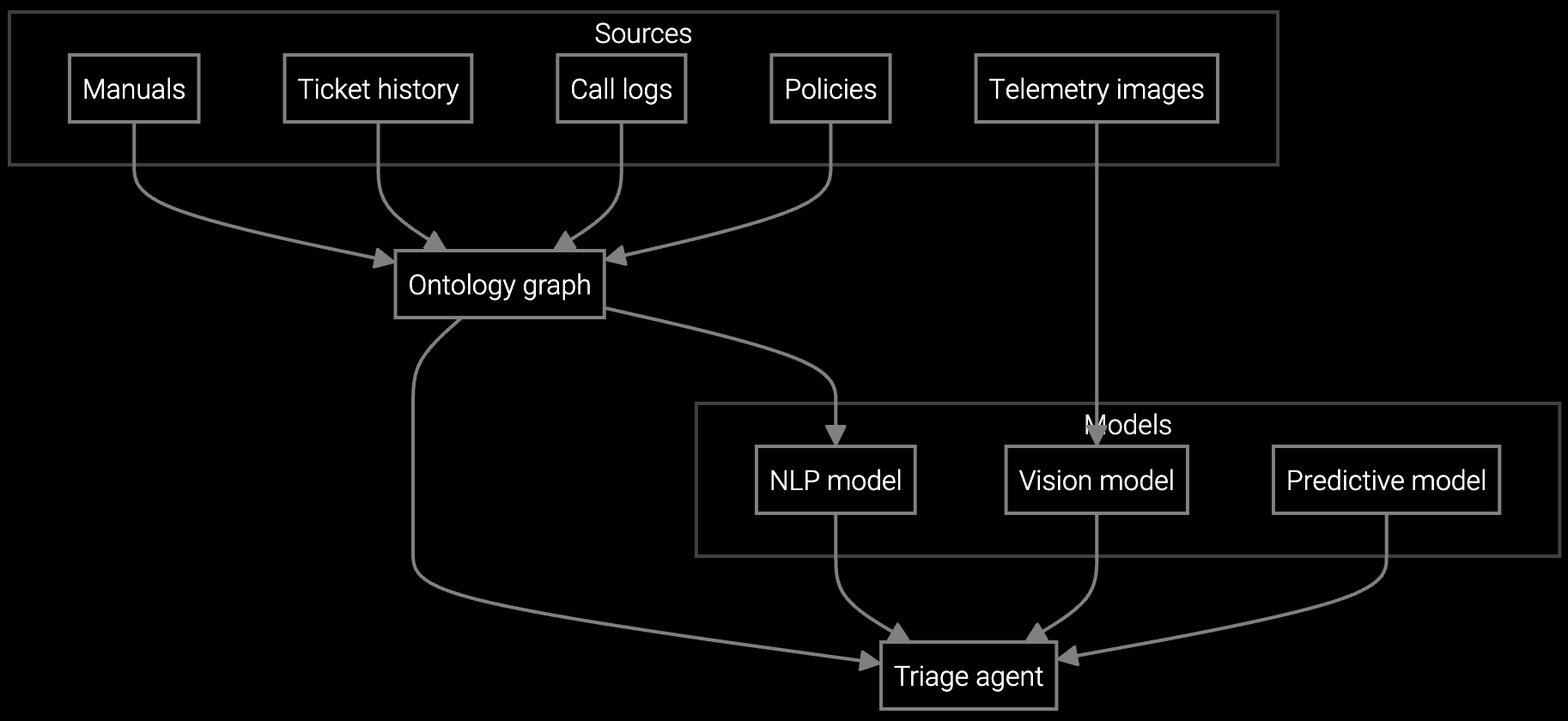

Automatically classify incoming cases by equipment model, failure mode, and warranty status to route issues to the right specialist queue with diagnostic context.

Generate instant summaries from multi-channel case histories so agents understand equipment context, prior repairs, and customer concerns without reading through years of interactions.

Analyze equipment age, repair history, and part availability to recommend whether customers should repair aging machinery or plan for replacement, improving resolution quality.

Industrial equipment manufacturers face a unique strategic challenge: machinery deployed 15-20 years ago requires support from contact centers built for modern response times. Customers expect immediate answers about CNC machines purchased in 2005 or turbines from 2010, but documentation quality degrades over time and experienced agents retire.

AI platforms trained on decades of case histories, repair logs, and equipment manuals bridge this gap. Agents access instant answers about legacy equipment configurations while maintaining consistency across your installed base. This strategic advantage matters most when competing OEMs struggle to support aging fleets, turning aftermarket service into a retention and revenue driver.

Initial deployment takes 6-8 weeks including CRM integration, model training on historical case data, and pilot rollout to one agent team. Full contact center rollout typically completes within 4-6 months depending on the number of product lines and system integrations required.

Yes. Platforms train on actual case resolution histories, not just manuals. If agents successfully resolved issues with 2005-era equipment, the AI learns from those interaction patterns even when official documentation is sparse. This makes hybrid approaches especially valuable for long-lifecycle manufacturers.

Hybrid platforms offer API access to customize workflows while maintaining core automation capabilities. You can modify case routing logic, add equipment-specific validation rules, or integrate proprietary diagnostic tools without rebuilding the entire system from scratch.

Track first-contact resolution rates, average handle time, and agent confidence scores by equipment line. Compare pilot teams using AI assistance against control groups handling similar case volumes. Most industrial manufacturers see measurable improvements within 60-90 days of initial deployment.

No. Hybrid platforms integrate with legacy CRM systems through standard APIs. Waiting delays value capture while competitors improve their service capabilities. Deploy AI now using existing systems, then migrate integrations when your CRM upgrade completes.

Transforming appliance support with AI-powered resolution.

Understanding and optimizing the issue resolution curve.

Vision AI solutions for EV charging support.

See how hybrid platforms balance control and speed for industrial equipment manufacturers.

Schedule Strategic Review