Connected refrigerators and HVAC systems send telemetry now. Your spreadsheet can't keep up, and manual data entry is burying your team.

Connected appliances generate telemetry that spreadsheets can't handle. The winning approach automatically syncs asset data from IoT streams, eliminating manual updates while giving you real-time visibility into configuration drift and maintenance windows.

You update the spreadsheet when equipment ships. Then customers change setpoints, update firmware, swap components. Your records are obsolete before the warranty call comes in.

Every warranty claim needs model, serial, install date, and firmware version. Someone has to hunt through emails and PDFs to fill in missing fields. Your service queue backs up while you find data.

You learn a compressor is failing when the customer calls. By then their food spoiled and they're posting angry reviews. The telemetry was there—you just couldn't monitor thousands of units.

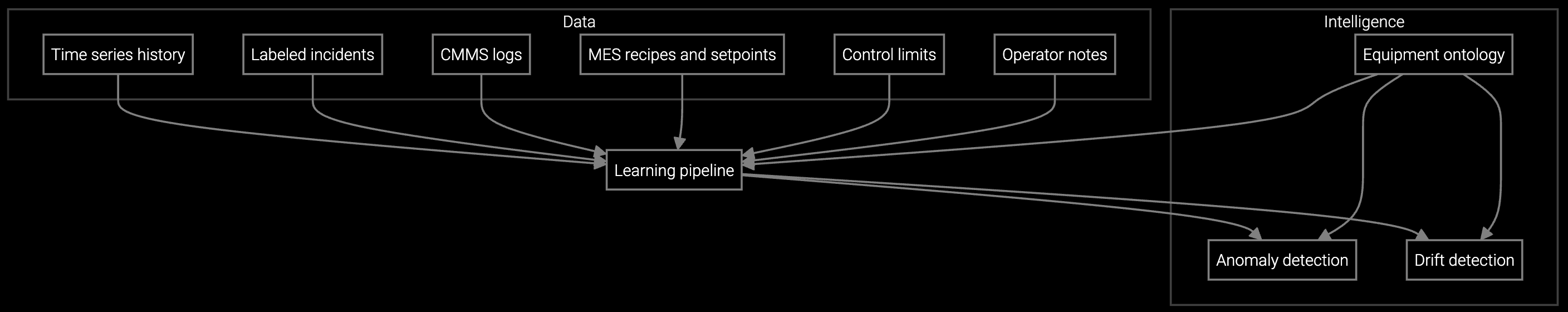

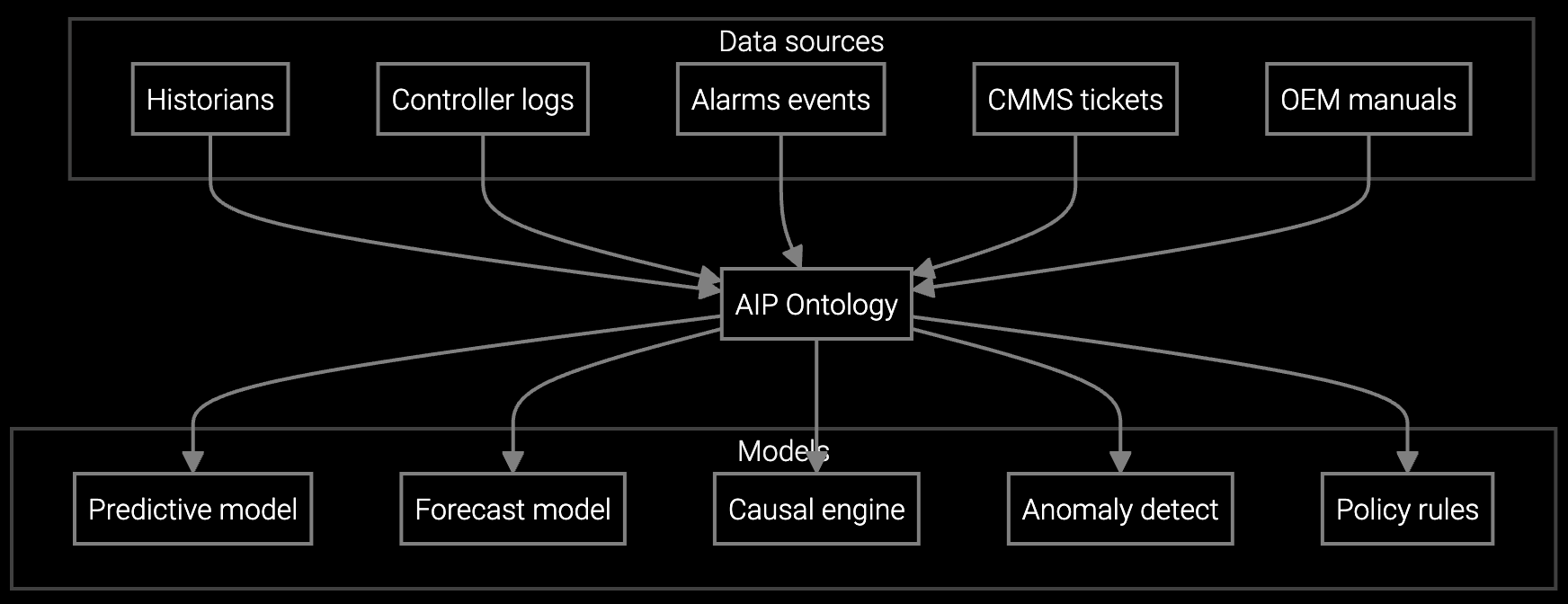

Stop updating spreadsheets. Connected refrigerators, dishwashers, and HVAC systems already send telemetry streams—temperature readings, cycle counts, error codes. The platform ingests these streams and automatically maintains your asset registry.

When a refrigerator's compressor runs hot for three consecutive days, the system flags it for proactive outreach before food spoils. When firmware versions drift across a product line, you see which units need updates. When warranty expiration approaches, renewal opportunities surface automatically.

This isn't a project for your IT team to build. Bruviti connects to standard IoT platforms—your existing telemetry infrastructure. Deploy in days, not quarters. Your job becomes reviewing flagged issues instead of hunting for data.

Monitors refrigerator temperature readings and compressor cycles to alert when behavior deviates from normal patterns before failure.

Estimates when HVAC filters or compressor components need replacement based on usage cycles and environmental conditions.

Analyzes dishwasher and washing machine telemetry to identify early fault patterns—water flow anomalies, cycle irregularities.

Your customers buy refrigerators expecting them to just work. When a compressor fails and food spoils, they don't care about root cause—they want their $400 of groceries replaced and a working fridge by tomorrow. That's the warranty claim hitting your P&L.

Connected appliances give you early warning. Temperature creeping up over 72 hours? Compressor running more cycles than normal? These signals predict failure days before food spoils. But only if you're monitoring thousands of units automatically instead of waiting for angry calls.

Start with the products that are already sending telemetry—premium refrigerators, smart HVAC systems, commercial kitchen equipment. Build the foundation now so you're ready as connectivity rolls out across product lines. Manual data entry for legacy units can coexist with automated tracking for connected ones.

When a warranty claim comes in, the system already has model, serial, install date, firmware version, and recent telemetry. You verify and approve instead of hunting through emails and PDFs to reconstruct the equipment history. That 3-5 hours per week becomes 20 minutes of review time.

Yes. The platform ingests firmware version from IoT telemetry streams and flags units running outdated versions. When you push a critical update for refrigerator compressor control logic, you see exactly which serial numbers need attention and can prioritize by warranty exposure or customer segment.

The system tracks configuration changes over time and flags drift that impacts performance or warranty coverage. If a customer changes HVAC setpoints outside recommended ranges and then files a warranty claim, you have the telemetry history to validate entitlement and understand root cause.

No. Bruviti integrates with standard IoT platforms through APIs. Your telemetry streams stay where they are—the platform subscribes to relevant data feeds and syncs asset records automatically. This is a data integration, not an infrastructure replacement.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how appliance manufacturers are automating asset tracking with IoT telemetry.

See the Platform