Manual asset tracking fails when equipment spreads across decades and continents.

Automate asset tracking, configuration management, and lifecycle workflows using APIs that connect your asset registry, telemetry feeds, and ERP. Detect configuration drift, trigger maintenance workflows, and identify upgrade candidates without manual data reconciliation.

Asset registry data lives in multiple systems. Field service updates one database, warranty claims update another, and telemetry feeds a third. Engineers spend hours reconciling records before each maintenance cycle.

Configuration drift detection happens during failure investigations, not before. You discover firmware mismatches after equipment fails, then scramble to audit the rest of the fleet.

Contract renewal windows pass unnoticed. Upgrade-eligible equipment runs outdated components. EOL notices arrive after inventory decisions lock in. No automated workflow connects asset state to business action.

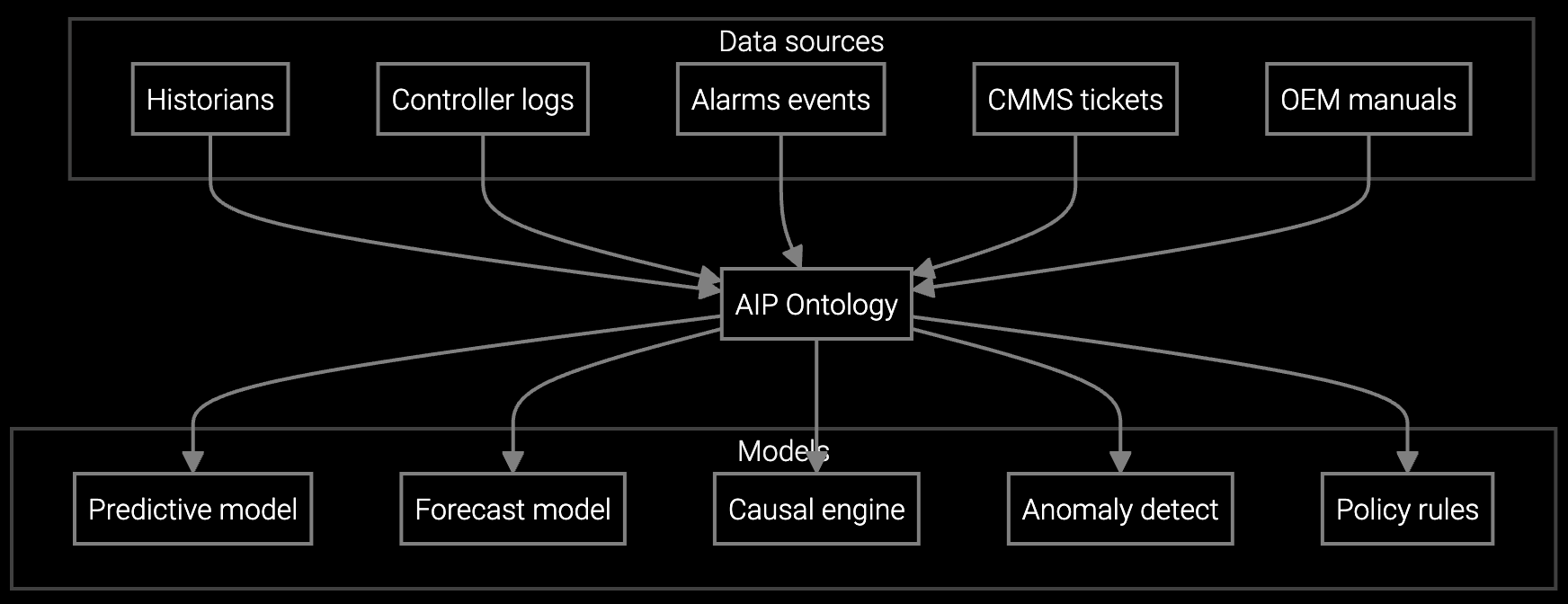

Event-driven APIs connect your asset registry, telemetry infrastructure, and business systems. When a configuration change occurs, the platform detects the drift, updates the asset record, and triggers downstream workflows without manual intervention. Your existing Python scripts and orchestration tools call RESTful endpoints to query asset states, register lifecycle events, and retrieve recommended actions.

Webhook subscriptions push real-time notifications when asset conditions cross thresholds. Integrate predictive maintenance scheduling with your CMMS. Route contract renewal alerts to your CRM. Build custom dashboards using GraphQL queries that span asset history, telemetry patterns, and warranty entitlements. The platform handles data normalization across legacy and modern systems, so your workflows operate on a unified asset model.

Analyzes IoT telemetry from CNC machines and pumps to identify anomalies before failures disrupt production lines.

Estimates component lifespan for industrial robots based on run hours and vibration patterns, enabling planned maintenance windows.

Schedules maintenance for compressors and turbines based on actual condition rather than fixed intervals, reducing downtime.

Industrial equipment operates for 10-30 years across global sites. A CNC machine sold in 2005 still runs daily, but its control software predates your current ERP. Pumps and compressors deployed in remote oil fields stream telemetry through protocols your modern systems don't natively parse. Configuration tracking relies on tribal knowledge because original documentation disappeared with retired engineers.

Automated workflows must bridge this gap. APIs normalize data from PLCs, SCADA systems, and legacy databases into a unified asset model. Event-driven architecture detects when a field engineer swaps a component without updating records. Webhooks trigger contract renewal workflows 90 days before service agreements expire, giving sales teams time to engage customers before competitors do.

RESTful endpoints accept JSON payloads for asset registration, configuration updates, and lifecycle events. GraphQL queries support complex asset history retrieval. Webhooks push notifications in JSON format when conditions trigger. Legacy SCADA and PLC protocols are normalized through adapter middleware before reaching the API layer.

Configuration baselines are defined per model and vintage. The platform compares telemetry-reported firmware versions, installed components, and operating parameters against expected configurations. When drift exceeds thresholds, webhooks notify your orchestration layer with asset ID, drift type, and recommended corrective action. Your custom workflows decide whether to auto-remediate or escalate for human review.

Yes. Define custom rules using Python or TypeScript SDKs. For example, trigger contract renewal workflows when run hours exceed 80% of warranty coverage, or flag upgrade candidates when telemetry shows performance degradation patterns. Rules execute server-side and can invoke external APIs to update CRM records or create service tickets.

Use bidirectional APIs to sync asset states. When the platform detects a maintenance trigger, it posts a work order to your CMMS via their REST API. When field service updates the CMMS, webhooks notify the asset registry to update configuration records. Pre-built connectors exist for SAP, Oracle, and major CMMS platforms. Custom integrations use standard OAuth 2.0 authentication and webhook subscriptions.

Telemetry ingestion to anomaly detection notification typically runs under 60 seconds. High-priority alerts trigger webhooks within 5-10 seconds of threshold crossing. Batch configuration audits run on scheduled intervals you define. For critical equipment, configure continuous monitoring with sub-second detection for catastrophic failure patterns.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

Talk to our API team about integrating asset tracking workflows with your existing infrastructure.

Schedule Technical Review