Manual registration, disconnected IoT data, and legacy ERP gaps leave millions in service revenue unrealized.

Automating asset lifecycle workflows in appliance manufacturing connects registration, IoT telemetry, and service systems to maintain real-time configuration accuracy, trigger proactive maintenance, and flag upgrade opportunities without manual data reconciliation.

Consumers skip registration, installers bypass serial capture, and IoT-enabled appliances ship without provisioning. You lose visibility the moment products leave the dock.

Firmware updates, part replacements, and field modifications go unrecorded. Your asset registry shows a snapshot from factory shipment, not current state.

Without proactive visibility into aging equipment and usage patterns, renewal reminders arrive late or not at all. High-value customers churn silently.

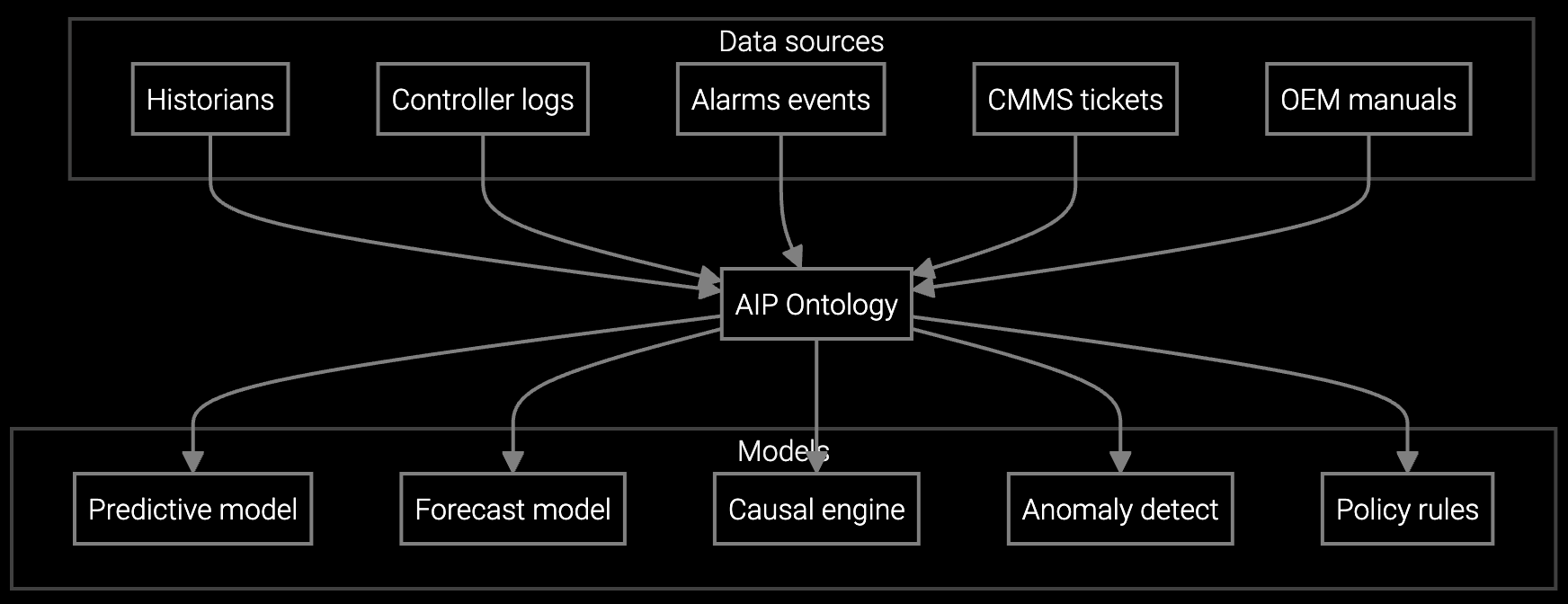

Bruviti's asset lifecycle automation operates as an event listener across your registration portals, IoT telemetry streams, and service transaction logs. When a refrigerator gets provisioned, a firmware update completes, or a service call closes, the platform captures the state change, validates it against configuration rules, and triggers downstream workflows—contract renewal flags, predictive maintenance schedules, or upsell recommendations—without custom integration code.

You define lifecycle rules in Python or TypeScript, not proprietary workflow builders. The platform exposes REST APIs for asset state queries and webhook endpoints for outbound triggers. Your data stays in your systems; Bruviti orchestrates the cross-system logic that keeps asset records accurate and service workflows automated. No vendor lock-in, no black-box decisioning, and no middleware maintenance burden.

Analyzes HVAC compressor telemetry and dishwasher error logs to flag anomalies before consumers report failures, enabling proactive service outreach.

Estimates when refrigerator compressors and washing machine motors will fail based on cycle counts and operating conditions, triggering maintenance windows during low-demand periods.

Schedules water heater anode rod replacements and ice maker cleanings based on actual usage patterns, not fixed calendar intervals, reducing premature failures.

Appliance OEMs face thin margins, seasonal demand spikes, and consumers who expect refrigerators and HVAC systems to outlast mortgages. Connected appliances promised proactive service but delivered integration headaches—IoT platforms disconnected from warranty systems, registration portals ignored by installers, and ERP records that reflect factory config, not field reality.

Automated asset lifecycle workflows close these gaps by treating every IoT heartbeat, service transaction, and warranty claim as a trigger to update the asset record and evaluate next actions. When a commercial ice machine reports elevated condenser temperatures, the system flags it for preventive maintenance before summer rush. When a smart washer hits 2,000 cycles, it becomes an extended warranty upsell candidate. These workflows run continuously, require no manual reconciliation, and integrate with existing SAP or Oracle systems via standard REST APIs.

The platform ingests service call records, warranty claims, and manual registration data as lifecycle events. Even without telemetry, transaction history triggers workflows like renewal eligibility checks and parts EOL notifications. You gain workflow automation on the entire installed base, not just connected products.

REST endpoints for asset state queries, configuration change logs, and lifecycle event history. Webhook triggers for outbound notifications to CRM, ERP, or custom service scheduling tools. Python and TypeScript SDKs let you define custom rules—like flagging high-cycle washers for extended warranty offers—without vendor-specific scripting languages.

Yes. You define acceptable drift thresholds and mandatory fields per product line using version-controlled YAML configs or SDK code. The platform validates incoming telemetry and service records against these rules, flagging discrepancies for review or auto-correction based on your preferences.

Your asset records remain in your ERP or MDM system. Bruviti maintains an event log and workflow state cache, not a duplicate asset registry. Queries pull current data from your source systems via API; updates write back through the same integration. You retain full data sovereignty and can disconnect at any time without data migration.

Most appliance OEMs observe a 15-20% lift in renewal attachment within the first quarter after deploying automated eligibility detection and outreach triggers. The workflow runs continuously, so improvements compound as more products enter renewal windows with accurate asset data and timely reminders.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how Bruviti integrates with your existing systems without vendor lock-in.

Schedule Technical Demo