Manual asset updates across legacy systems cost hours daily and miss contract renewal windows before they close.

Automated asset tracking consolidates registration, configuration updates, and contract linkage into unified workflows. AI reads sensor data, detects configuration drift, and flags renewal opportunities without manual data entry.

Equipment deployed without registration creates blind spots. When pumps or compressors fail in remote sites, you can't verify warranty status or pull maintenance history.

Field modifications and firmware updates don't flow back to central records. Your system shows baseline config while the turbine in Texas runs custom PLC logic.

No automated alerts for expiring service agreements. By the time you notice the contract lapsed, the customer already evaluated your competitor's offer.

Bruviti consolidates asset registration, configuration tracking, and contract management into one interface. When a CNC machine ships, the platform auto-creates the asset record from ERP data and links the service contract. When PLC firmware updates in the field, the platform detects the change through telemetry streams and updates configuration history automatically.

The system monitors contract expiration dates and surfaces renewal opportunities 90 days ahead. You review a pre-built list of accounts at risk, sorted by equipment value and failure probability, instead of manually scanning spreadsheets for dates. Contract attachment happens in the same screen where you view equipment health—no switching between finance and operations systems.

Monitors vibration and temperature data from compressors and turbines to flag deviations before failures impact production uptime.

Uses run hours and sensor patterns to recommend maintenance windows for heavy machinery, reducing unplanned downtime.

Estimates when critical components will fail based on usage patterns, enabling planned part orders and service visits.

Industrial equipment stays in service for decades. A turbine installed in 2005 still generates revenue today, but its serial number lives in a discontinued AS/400 system and its latest firmware version exists only in a field tech's notebook. When that turbine throws a fault code, you can't pull its modification history or verify which parts kit applies.

Automated asset tracking bridges this gap. The platform ingests data from legacy databases, modern IoT sensors, and manual field updates into one timeline. When a pump's pressure sensor reads high, you see the complete picture: original spec, three retrofit upgrades, and last month's firmware patch. This unified view eliminates guesswork and reduces diagnostic time.

The platform ingests data from legacy systems through batch uploads or API connections, then enriches records over time as field updates and sensor data arrive. You don't need complete historical data to start—each service interaction adds detail to the asset timeline.

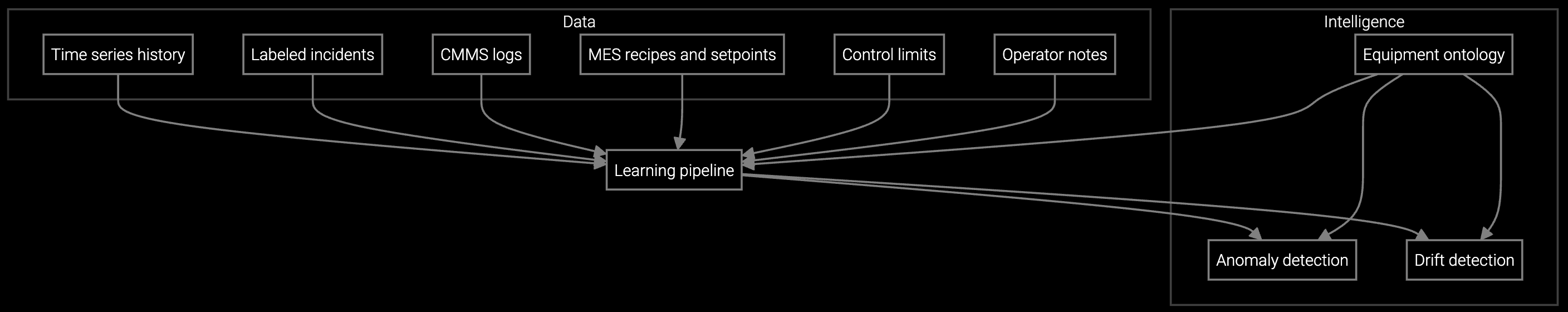

AI monitors telemetry streams for changes in firmware versions, software parameters, or hardware modifications. When a field tech updates PLC logic or swaps a component, the platform compares new sensor signatures against baseline records and flags discrepancies for review.

Yes. The platform ranks expiring contracts by equipment criticality, failure probability from predictive models, and customer lifetime value. This lets you focus renewal efforts on high-impact accounts rather than processing renewals in date order.

Initial integration typically takes 4-6 weeks depending on the number of source systems. The platform connects to ERP, CRM, and SCADA systems through APIs or scheduled batch imports. Once connected, updates flow automatically without manual reconciliation.

The platform creates a provisional asset record using available identifiers like customer site and equipment model. As service interactions occur, it prompts for serial number entry and links the new data to the provisional record, gradually completing the asset profile.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

Connect your asset data and contract systems to see how Bruviti consolidates workflows.

Schedule Demo