Manual asset tracking costs operators hours daily switching between systems just to verify equipment status and service history.

Automated asset tracking replaces manual data entry with real-time configuration monitoring, predictive maintenance scheduling, and contract renewal alerts, reducing operator workload while improving asset visibility across your deployed appliance base.

Operators spend hours copying serial numbers, firmware versions, and service dates between five different systems. Every product registration requires 8-12 fields entered manually across disconnected databases.

Equipment in the field deviates from records without operators noticing. Firmware updates happen off-schedule, parts get swapped without documentation, and asset records become unreliable within months of installation.

Service contracts expire before operators notice because renewal tracking lives in spreadsheets instead of automated workflows. Equipment falls out of coverage, customers discover gaps only when filing claims.

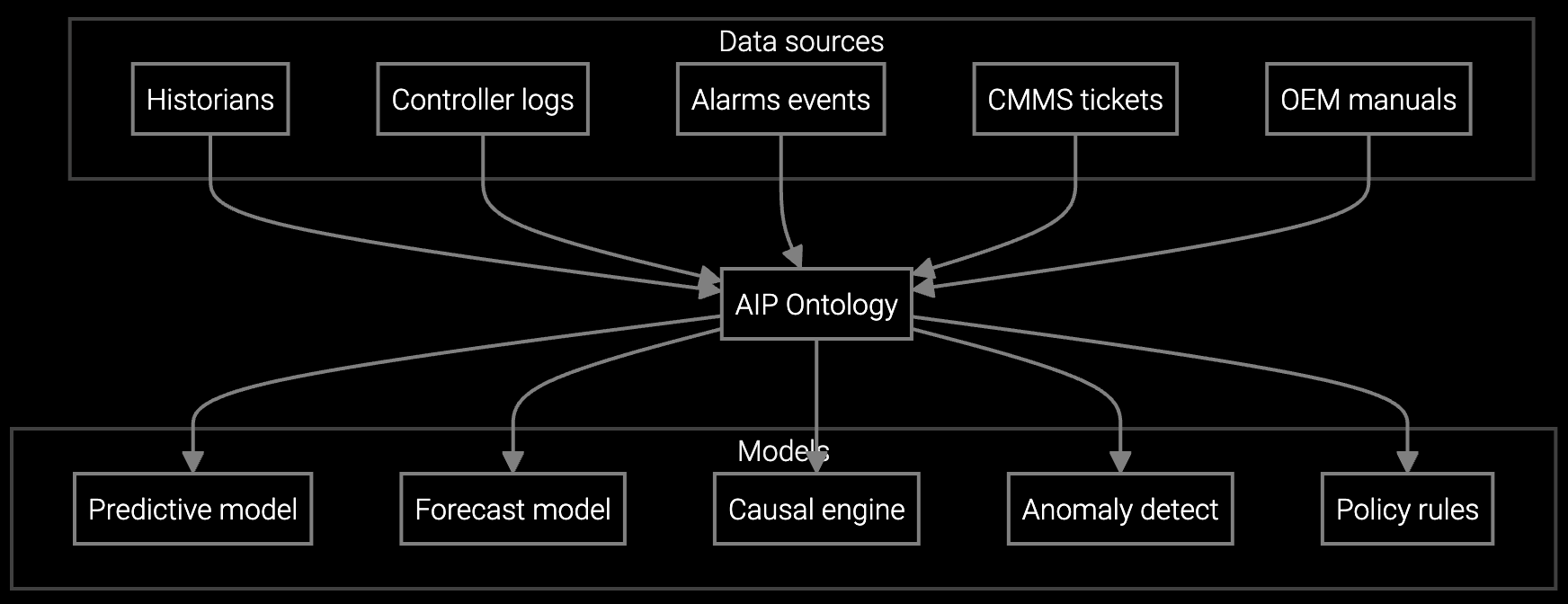

The platform automatically ingests asset data from IoT telemetry, service logs, and registration systems into a unified view. Configuration changes detected through connected appliances update records without operator intervention. Firmware versions sync in real-time. Serial number lookups return complete equipment history instantly.

Predictive maintenance schedules auto-populate based on usage patterns and failure probability models. Contract expiration alerts trigger 90 days before renewal deadlines with customer contact details pre-filled. Operators review system-generated renewal cases instead of manually tracking spreadsheets across thousands of appliances.

Monitors IoT telemetry from refrigerators, HVAC units, and water heaters to detect anomalies before appliances fail in customer homes.

Auto-schedules maintenance for commercial kitchen equipment based on actual usage patterns rather than fixed intervals.

Estimates when washing machine motors or dishwasher pumps will fail, enabling planned service windows before breakdowns occur.

Appliance manufacturers track warranty claims across refrigerators, washers, HVAC systems, and water heaters with 10-15 year lifespans. Asset databases grow into millions of records. Connected appliances generate telemetry streams requiring constant configuration monitoring. Seasonal demand spikes in summer (air conditioners) and winter (furnaces) stress manual tracking systems.

Automated workflows handle this scale by ingesting IoT data from connected thermostats, smart refrigerators, and networked HVAC units without operator review. Configuration baselines update when manufacturers push firmware remotely. Operators focus on exception cases flagged by anomaly detection rather than reviewing normal equipment operation across the entire installed base.

The platform ingests asset data directly from IoT telemetry, service logs, and registration systems, eliminating manual entry of serial numbers, firmware versions, and service dates. Configuration changes detected through connected appliances update records automatically, reducing operator workload from hours to minutes per day.

Automated monitoring compares real-time telemetry from connected appliances against configuration baselines. When firmware updates happen off-schedule or parts get swapped without documentation, the system flags discrepancies for operator review rather than letting records become unreliable over time.

The platform auto-generates renewal alerts 90 days before service contract expiration dates, pre-populating customer contact details and coverage terms. Operators review system-generated cases instead of manually tracking spreadsheets, increasing renewal rates by eliminating missed deadlines.

Yes. For non-connected equipment, the platform uses historical service records and failure patterns to estimate remaining useful life and schedule maintenance. Connected appliances provide richer telemetry, but predictive models work with installation date, usage estimates, and past repair data for legacy equipment.

Serial number lookups return full asset history instantly from the unified view, replacing manual searches across five disconnected systems. Operators see firmware versions, service dates, warranty status, and contract details in one screen, reducing lookup time from 5-8 minutes to under 30 seconds.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

Watch how zero-touch asset management eliminates manual data entry and improves configuration accuracy.

Schedule Demo