Incomplete asset visibility costs appliance OEMs millions in missed service revenue and contract renewals each year.

Appliance OEMs face a strategic choice: build custom asset tracking systems requiring 12-18 months and specialized teams, buy rigid vendor platforms risking lock-in, or adopt API-first solutions that deliver immediate visibility while preserving integration flexibility and enabling proactive service transformation.

Missing serial numbers and configuration gaps prevent proactive service. When installed units lack complete records, service contracts go unsold and warranty reserves stay bloated because you cannot predict failures you cannot see.

Field equipment diverges from records as firmware updates, repairs, and retrofits occur. Incorrect configuration data undermines troubleshooting accuracy and forces service teams to start from scratch on every call.

Without lifecycle visibility, every failure is a surprise. Appliance OEMs cannot identify upgrade candidates, predict maintenance windows, or intervene before customer-facing failures erode brand loyalty.

Building in-house gives full control but demands 12-18 months, dedicated ML engineers, and ongoing model retraining as product lines evolve. Off-the-shelf vendor systems deploy faster but impose rigid schemas that rarely fit appliance service workflows and lock you into proprietary formats when integration needs change.

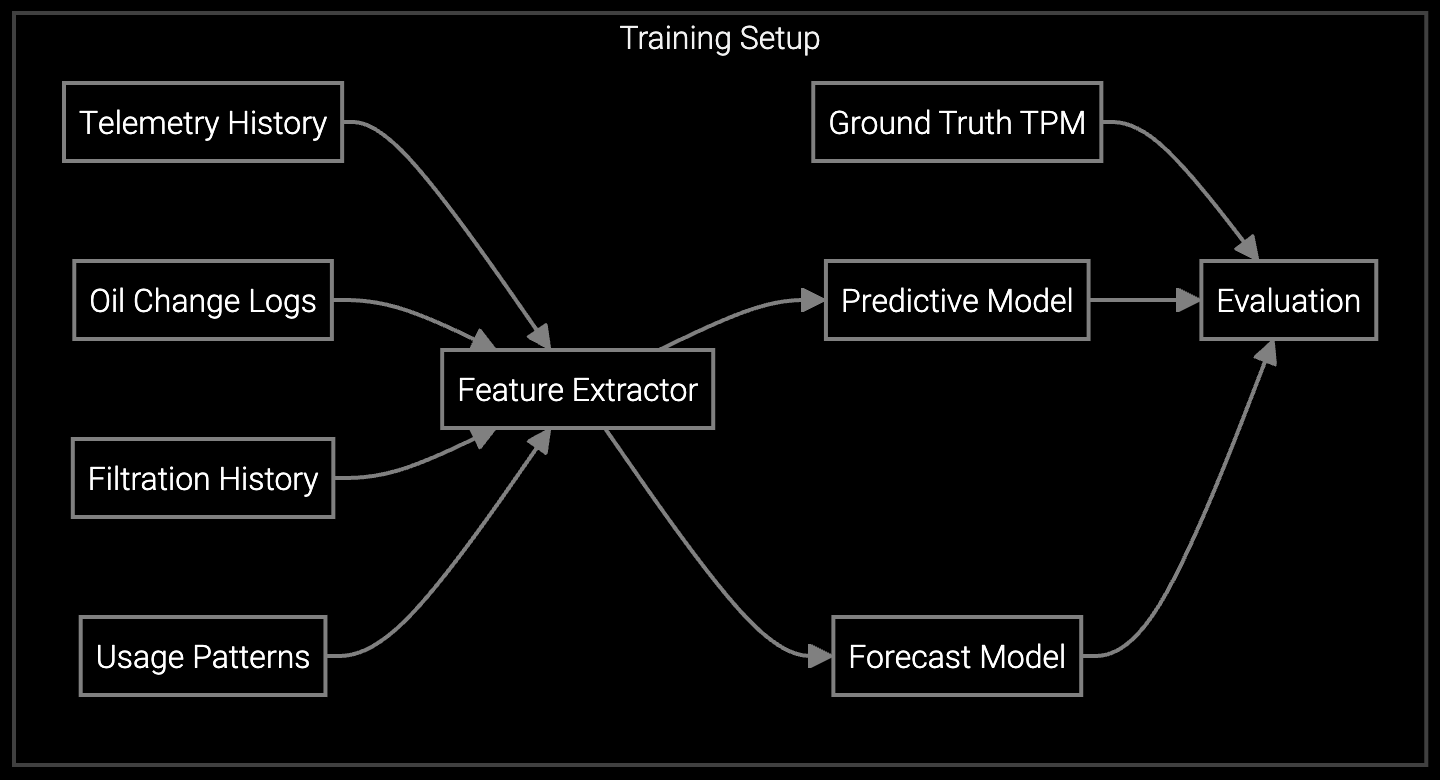

API-first platforms deliver pre-trained models for immediate asset tracking while preserving full integration flexibility. Bruviti ingests registration data, IoT telemetry from connected appliances, and service history to generate real-time configuration snapshots. The platform identifies coverage gaps, flags configuration drift, and surfaces contract renewal opportunities without forcing you into a closed ecosystem. Start with out-of-the-box asset visibility, then extend with custom lifecycle rules as your strategy matures.

Virtual models track refrigerator compressor performance, HVAC heat exchanger efficiency, and dishwasher pump health in real time—enabling proactive service before customer-facing failures occur.

Predicts when washer drum bearings or water heater heating elements will fail based on usage patterns, enabling planned maintenance windows that protect brand loyalty.

Schedules HVAC filter replacements and refrigerant checks based on actual equipment condition rather than fixed intervals—reducing service costs while improving uptime.

Appliance OEMs operate on thin margins where service cost control separates profit from loss. Connected appliances generate IoT telemetry streams that promise proactive service, but only if that data links to complete asset records. When refrigerators, HVAC systems, and water heaters lack accurate configuration histories, warranty claims spike, contract attachment rates fall, and competitors offering predictive maintenance steal market share.

The strategic window is closing. OEMs who establish lifecycle visibility now can shift from reactive break-fix models to proactive service contracts priced on uptime guarantees. Those who delay face margin erosion as warranty reserves climb and service contract revenue stagnates.

Most appliance OEMs measure contract attachment lift within 90 days of deployment. Initial ROI comes from identifying existing coverage gaps—units in the field eligible for service contracts but missing from CRM systems. Long-term margin protection builds as predictive maintenance reduces warranty claims and proactive interventions prevent customer-facing failures that damage brand reputation.

Real-time telemetry integration and service event logging keep records synchronized with field reality. When connected appliances report firmware updates, IoT sensors detect component replacements, or service tickets document repairs, the platform updates configuration snapshots automatically. Continuous reconciliation prevents the manual record-keeping failures that cause drift in legacy systems.

Connected appliances deliver faster ROI because IoT telemetry provides immediate visibility into usage patterns and failure precursors. However, legacy products often represent larger installed base volume and higher warranty exposure. A phased approach pilots with connected lines to prove value quickly, then expands to legacy products using service history and registration data to fill visibility gaps.

Open APIs expose all platform capabilities and data access without proprietary formats. You can build custom lifecycle rules, integrate with any CRM or ERP system, and extract asset data for external analytics without permission gates or conversion fees. If business needs change, integration patterns adapt without rip-and-replace migrations that characterize closed vendor platforms.

Track asset data completeness rates, configuration accuracy scores, contract attachment rates per product line, and time-to-resolution for service inquiries. Leading indicators appear first—coverage gaps close, configuration mismatches drop. Lagging financial metrics follow within 6 months—warranty reserve reductions, service contract revenue growth, and first-call resolution improvements that reduce contact center costs.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how appliance OEMs use Bruviti to close coverage gaps and drive contract attachment.

Schedule Strategic Review