Seasonal demand spikes and decades of product models demand service systems that scale without proportional cost increases.

Appliance manufacturers face rising contact volumes and thin margins that demand service cost control. A hybrid AI approach combines pre-built models for symptom triage and parts prediction with API extensibility for brand-specific workflows, delivering faster time-to-value than build while avoiding vendor lock-in.

Summer HVAC failures and holiday appliance breakdowns create seasonal surges that overwhelm fixed agent capacity. Traditional hiring cycles cannot respond fast enough, resulting in abandoned calls and NPS erosion during peak revenue periods.

Inconsistent diagnosis leads to unnecessary part shipments and preventable service calls. No Fault Found returns consume service budgets while extended troubleshooting increases average handle time and labor costs per case.

Agents must search multiple systems to find model-specific troubleshooting for decades of product lines. This slows resolution, increases training time for new hires, and creates inconsistent customer experiences across channels.

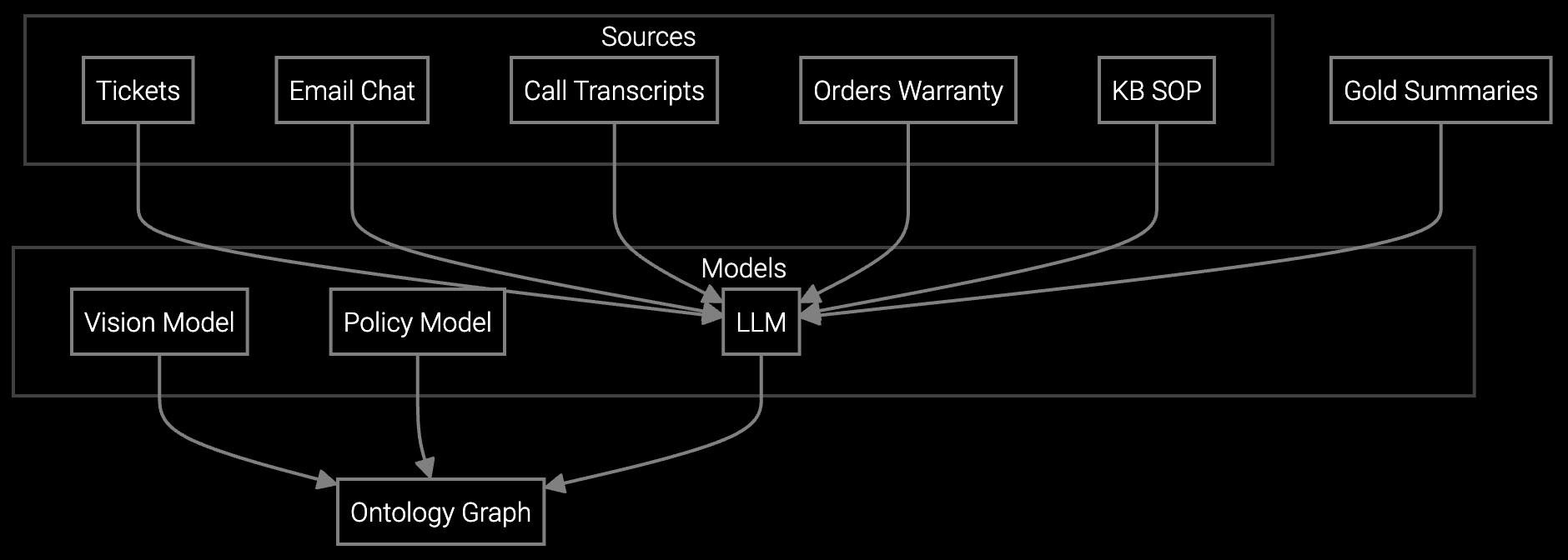

Building in-house demands AI expertise, labeled training data, and 18-24 months before production deployment. Buying traditional software locks you into rigid workflows that cannot adapt to your brand's service philosophy or integrate with legacy warranty systems. The platform delivers pre-trained models for symptom analysis and parts prediction that work immediately, while exposing APIs that let your team customize routing logic, integrate proprietary product data, and extend functionality without vendor dependency.

This approach protects margin during peak seasons by automating email triage and self-service resolution paths, reducing cost per contact while your agents focus on complex cases requiring human judgment. The platform learns from your historical case data to surface model-specific guidance, cutting handle time and improving first contact resolution without forcing agents to memorize decades of product documentation.

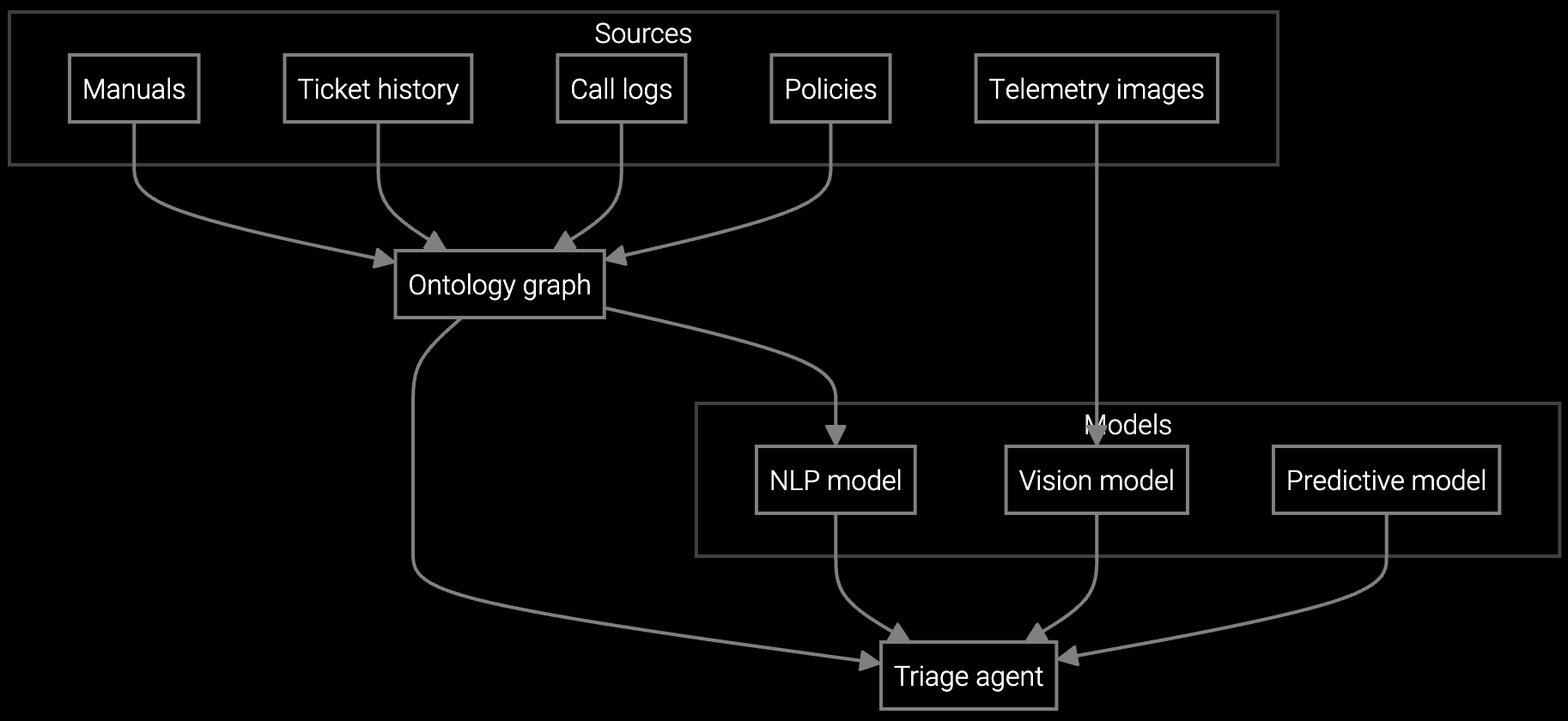

Automatically classify appliance symptoms from customer descriptions, correlate error codes with failure modes, and route cases to the appropriate resolution path without manual agent review.

Generate instant summaries from email threads, chat logs, and call transcripts so agents understand case history across channels without reading full interaction sequences.

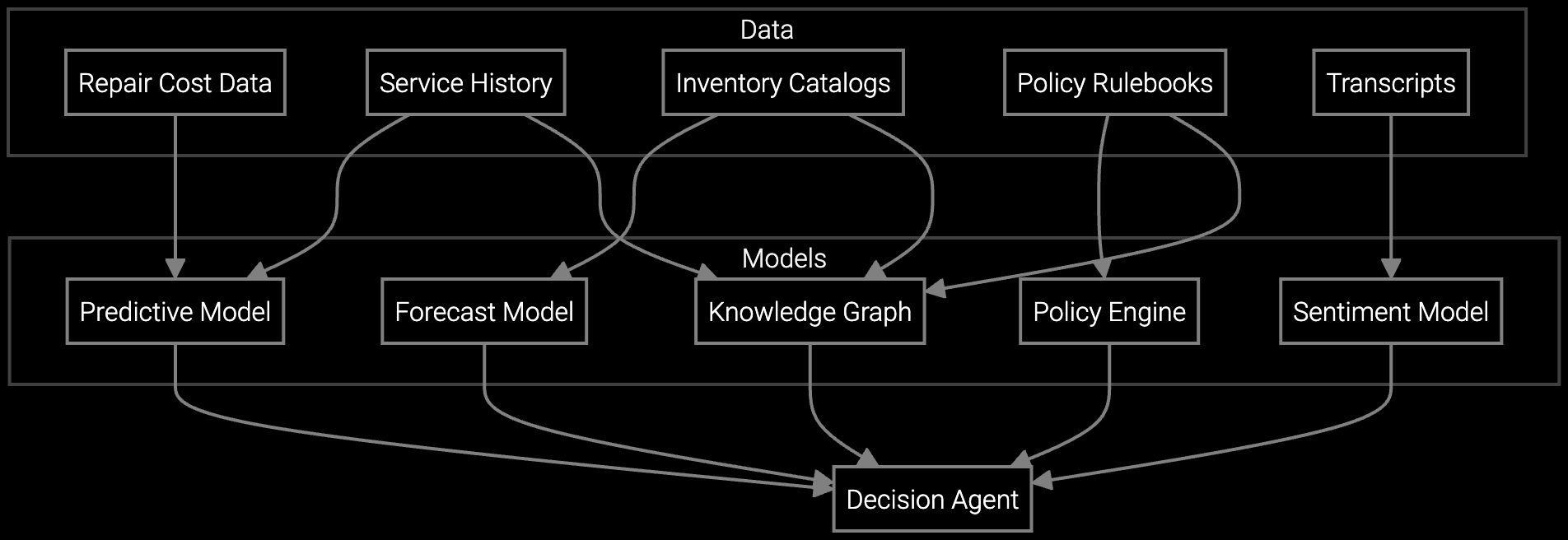

Analyze appliance age, failure mode, and part availability to recommend the most cost-effective resolution, reducing warranty costs while maintaining customer satisfaction.

Appliance manufacturers operate on thin margins where service costs directly impact profitability. The platform ingests model-specific documentation, error code libraries, and decades of service history to deliver symptom-based troubleshooting tailored to your product portfolio. This enables self-service deflection for common refrigerator and HVAC issues while guiding agents through complex diagnostic sequences for commercial equipment.

Integration with existing warranty management and parts logistics systems ensures AI recommendations respect entitlement rules and regional inventory constraints. Connected appliance telemetry feeds proactive case creation, catching failures before customers call and reducing emergency service costs during peak seasons when HVAC and refrigeration equipment operates under maximum stress.

Appliance manufacturers typically achieve positive ROI within 6-9 months through reduced average handle time and lower NFF rates. The fastest returns come from automating email triage and symptom-based self-service for high-volume product lines, which reduces cost per contact before expanding to more complex troubleshooting scenarios.

API-first architecture ensures you control integration points and can migrate AI models over time. Your case data, product documentation, and custom routing logic remain accessible through standard interfaces, preventing dependency on proprietary formats. This lets you adopt pre-built capabilities immediately while building internal AI expertise that can eventually replace purchased components if strategic priorities shift.

Consumers expect immediate resolution for home appliance failures but tolerate self-service only when it works faster than calling. Deploy AI to automate email responses and simple symptom troubleshooting where success rates exceed 70%, while routing complex issues directly to agents with diagnostic context already assembled. This reduces wait times for customers who need human help while deflecting cases where automation delivers faster outcomes.

Historical case data with symptom descriptions, resolutions, and part replacements provides the foundation. Model-specific service manuals, error code definitions, and warranty claim records improve accuracy. Connected appliance telemetry adds predictive capabilities but is not required for initial deployment. Most manufacturers have sufficient data in existing ticketing systems to achieve meaningful accuracy improvements within the first 90 days.

AI platforms integrate with existing CRM, ticketing, and warranty systems through APIs rather than replacing them. This protects prior technology investments while adding intelligence layers that improve agent productivity and customer outcomes. The hybrid approach lets you adopt AI capabilities incrementally without ripping out systems that still deliver value in other parts of the service organization.

Transforming appliance support with AI-powered resolution.

Understanding and optimizing the issue resolution curve.

Vision AI solutions for EV charging support.

See how hybrid AI delivers faster ROI than build while avoiding the lock-in risks of traditional software.

Schedule Strategic Discussion