Legacy contact centers can't handle today's complexity - but custom-building AI takes years you don't have.

Hybrid approaches deliver fastest ROI: deploy pre-trained AI for case triage and knowledge retrieval within 60 days, then customize workflows using APIs as complexity demands. Pure build requires 18-24 months; pure buy creates vendor lock-in and limits differentiation.

Building AI customer service capabilities internally requires assembling data science teams, collecting training data, and iterating models. Industrial OEMs lack the talent density and case volume velocity of pure software companies, extending development cycles and delaying competitive response.

Pure SaaS solutions promise fast deployment but trap contact center workflows inside proprietary systems. When business needs evolve or vendors raise prices, industrial OEMs face costly migrations and lost institutional knowledge embedded in the platform.

While deliberating build-versus-buy decisions, industrial equipment competitors deploy AI-assisted case resolution and capture market share. Delayed strategic choices compound into lost service contracts, diminished NPS scores, and weakened customer retention.

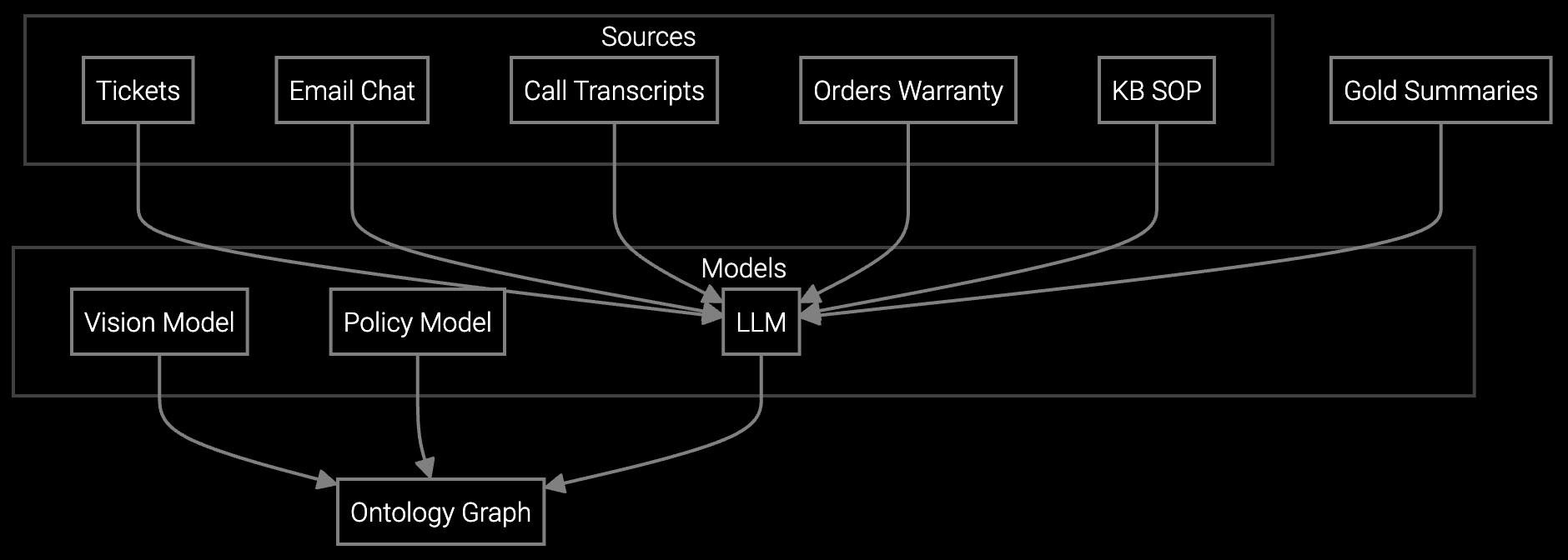

Bruviti's platform resolves the build-versus-buy dilemma by combining pre-trained foundation models with API-first customization. Deploy case triage and knowledge retrieval workflows within 60 days using models trained on industrial service scenarios, then extend functionality through Python SDKs as contact center complexity demands.

The architecture separates commodity AI tasks (email classification, sentiment analysis, routing logic) from differentiated workflows (warranty adjudication rules, parts recommendation engines, OEM-specific diagnostic trees). OEMs gain immediate productivity lift from proven models while retaining strategic control over proprietary service knowledge and customer interaction patterns.

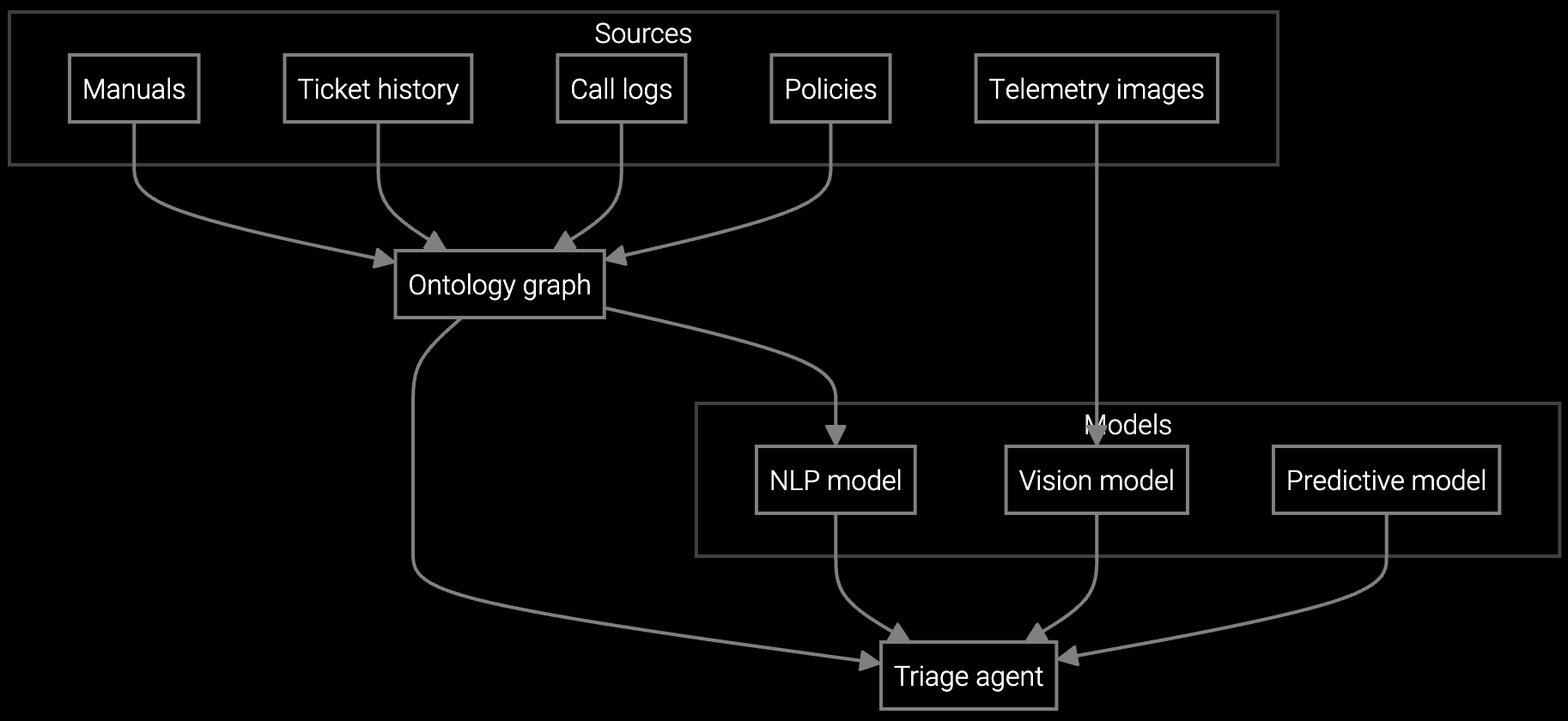

AI classifies incoming machinery issues by severity and routes pump failures, compressor alarms, and hydraulic problems to specialized agent teams with pre-loaded diagnostic context.

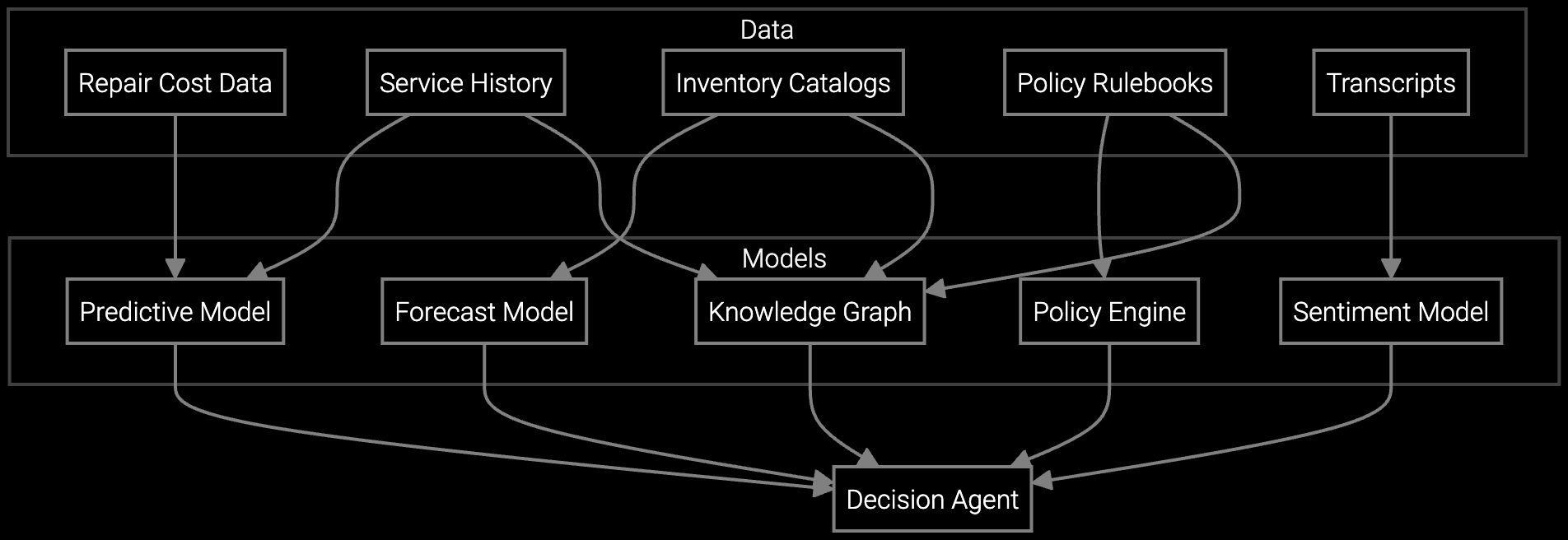

Automatically condenses multi-year service histories for CNC machines and industrial robots, surfacing prior failure patterns and resolution attempts to prevent repeated diagnostics.

Analyzes equipment age, failure modes, and part availability to guide agents toward cost-optimal resolutions for aging machinery nearing end-of-life thresholds.

Industrial OEMs face unique constraints: equipment lifecycles spanning decades, geographically dispersed service networks, and tribal knowledge concentrated in aging workforces. The hybrid strategy addresses these by starting with high-volume, repeatable contact center workflows (email triage for common pump failures, automated case routing for standard compressor alarms) where pre-trained models deliver immediate value.

After proving ROI on foundational automation, extend customization to differentiated scenarios: warranty adjudication rules specific to hydraulic systems, parts recommendation logic trained on proprietary failure modes, diagnostic trees reflecting decades of accumulated OEM expertise. This phased approach balances speed-to-value with strategic control over customer interaction quality.

Industrial OEMs typically measure first-value within 60-90 days by deploying pre-trained models on high-volume case types like email triage and knowledge retrieval. Cost-per-contact reductions of 15-20% appear in initial deployment phases, with full 28-35% impact realized after 6-9 months as customization extends to complex workflows.

API-first architecture separates data ownership from processing logic. Industrial OEMs retain full control over training data, custom models, and integration workflows through Python SDKs. If business priorities shift, transition costs remain bounded because proprietary service knowledge and customer interaction patterns exist in OEM-controlled code, not vendor-locked systems.

Yes, through staged customization. Start with foundation models trained on industrial service scenarios (pumps, compressors, motors) for immediate productivity, then train specialized models on OEM-specific failure modes using historical case data. The platform supports incremental refinement so customization compounds without disrupting operational workflows.

Building in-house requires 18-24 months to assemble data science teams, collect training data, and iterate models to production quality. Hybrid deployment achieves first-value in 60 days using pre-trained foundations, then enables gradual customization as internal expertise develops. This approach preserves strategic optionality while avoiding competitive disadvantage during build cycles.

Bruviti implements role-based approval thresholds where high-stakes decisions (warranty denial, equipment replacement) require human verification while routine actions (parts lookup, knowledge retrieval) execute autonomously. Audit trails log all AI recommendations and agent overrides, enabling continuous model refinement and compliance documentation for regulated industries.

Transforming appliance support with AI-powered resolution.

Understanding and optimizing the issue resolution curve.

Vision AI solutions for EV charging support.

Discuss phased deployment strategies that balance speed-to-value with strategic control.

Schedule Strategy Session