Decades-old machinery with missing serial numbers and undocumented modifications drain margins through missed renewals and surprise downtime.

Incomplete asset records cost industrial OEMs millions in missed renewals and unplanned downtime. AI-driven asset intelligence closes data gaps, attaches contracts to 95%+ of deployed equipment, and flags configuration drift before it triggers failures.

Legacy CNC machines and decades-old compressors sit in the field with no contract association. Your customers call for service, but you discover their entitlements expired years ago—or were never recorded. Revenue leaks through the gaps.

Actual equipment configurations diverge from your records after years of field modifications and retrofits. When critical components fail, you ship the wrong parts or dispatch service unprepared, extending downtime for your customers.

Equipment approaching end-of-life hides in the installed base because no one tracks run hours or condition data systematically. Preventable failures cascade into emergency service calls and SLA penalties.

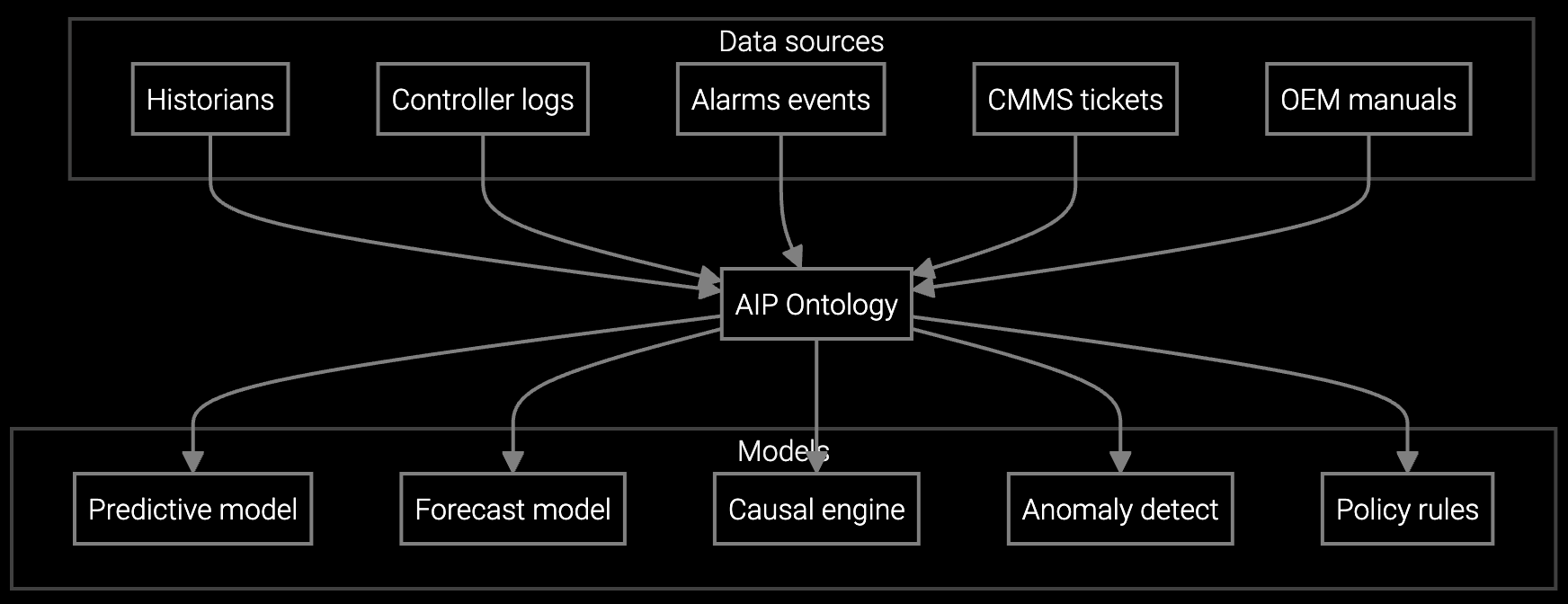

Bruviti's platform ingests equipment telemetry from PLCs, SCADA systems, and IoT sensors to build a continuously updated asset registry. The AI cross-references serial numbers, configuration states, and usage patterns against your service records, flagging discrepancies and filling gaps without manual data entry.

Instead of relying on outdated spreadsheets or incomplete ERP data, the platform tracks every machine's actual configuration, firmware version, and operational history. It alerts your team when equipment drifts from documented specs, when contracts approach expiration, or when predictive models detect early failure signals. Your service organization stops reacting to surprises and starts managing asset lifecycles proactively.

Monitors PLC and SCADA streams from CNC machines and compressors, detecting anomalies that signal component wear before failures occur.

Estimates when industrial equipment will reach end-of-life based on run hours and condition data, enabling planned replacement before emergency failures.

Schedules maintenance windows based on actual equipment condition rather than fixed intervals, reducing downtime and extending asset life.

Industrial OEMs manage equipment deployed across decades, from 1990s-era CNC machines still running on factory floors to modern IoT-enabled turbines in remote power plants. Each asset's configuration evolves through retrofits, firmware updates, and component replacements—changes rarely captured in central systems.

The platform ingests telemetry from legacy PLCs and modern IoT sensors alike, normalizing data across generations of equipment. It cross-references serial numbers against service histories, contract records, and parts shipments to reconstruct each machine's true configuration and lifecycle stage. When a 15-year-old compressor's vibration signature shifts, the AI correlates it with similar failures across your installed base and flags it for proactive maintenance before your customer's production line stops.

The platform ingests telemetry from equipment, cross-references serial numbers and configuration states against service records, and flags discrepancies. It uses machine learning to infer missing data from similar equipment patterns and automatically updates the asset registry. Manual verification is only required when confidence thresholds aren't met.

The AI can still enrich asset records by analyzing service call histories, parts shipment data, and manual inspection reports. When partial telemetry exists (like periodic PLC snapshots), the platform extrapolates usage patterns and condition estimates. Full predictive capabilities require sensor data, but contract attachment and configuration management work without it.

Most industrial OEMs see measurable gains within 90 days. The platform identifies unattached assets in the first data sync, allowing immediate outreach to customers for contract renewals. Configuration drift alerts start surfacing within weeks as telemetry flows in, reducing wrong-part shipments almost immediately.

Yes. Bruviti's platform normalizes data from disparate sources—legacy ERPs, CRM systems, service ticketing tools, and direct telemetry feeds. It reconciles conflicting records using confidence scoring and presents a unified asset view. No need to replace existing systems or force migrations.

Industrial OEMs typically recapture 12-18% of lost service revenue within the first year by attaching contracts to previously untracked assets. Reducing configuration drift cuts wrong-part costs by 20-30%, and predictive maintenance lowers unplanned downtime by 25-40%, protecting customer SLAs and your service margins.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how AI-driven asset intelligence can recapture millions in lost renewals and reduce unplanned downtime.

Schedule Demo