When you can't track millions of deployed units across decades of models, service costs spiral and contract renewals vanish.

AI-powered asset registries reconcile fragmented product data across legacy systems, automatically match serial numbers to configurations, and flag units approaching end-of-life. Complete visibility enables proactive service scheduling and doubles contract attachment rates.

Refrigerators, HVAC systems, and washers ship without registration. Years later, when failure patterns emerge, you can't identify affected units or notify owners proactively. Product recalls become guesswork.

Firmware updates, parts replacements, and retrofits leave actual equipment configurations different from what's recorded. Service dispatches fail because technicians arrive expecting the wrong configuration.

Without visibility into which units are approaching warranty expiration or end-of-support, contract renewal outreach happens too late or not at all. High-margin service revenue evaporates.

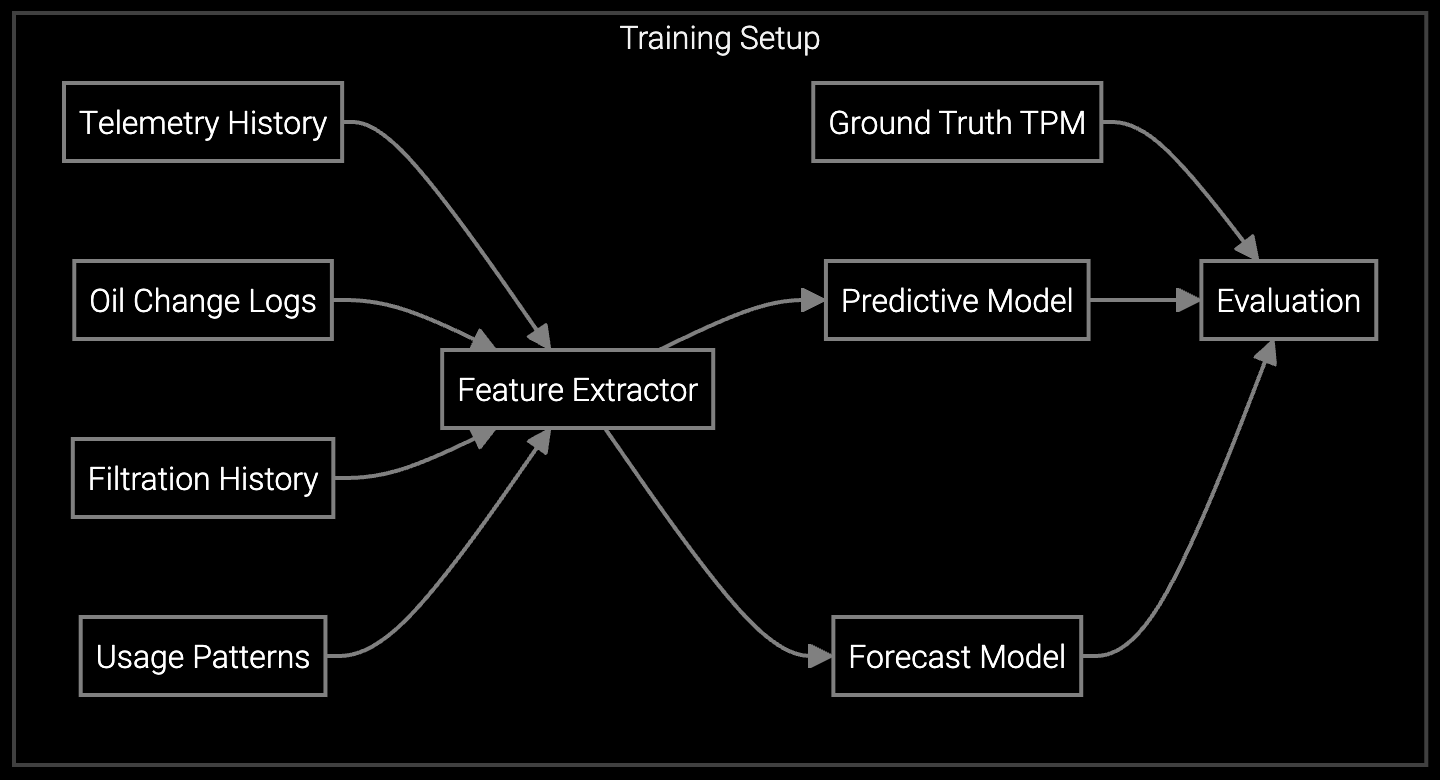

Bruviti's platform ingests fragmented product data from ERP systems, warranty databases, service tickets, and IoT telemetry streams. Machine learning models reconcile conflicting records, deduplicate entries, and infer missing serial numbers from installation dates, geographic patterns, and service history. The system builds a unified asset registry that tracks every deployed unit's configuration, location, firmware version, and maintenance history.

The platform continuously monitors this installed base for lifecycle events. When a refrigerator model reaches 80% of expected lifespan based on usage telemetry, it flags the unit for proactive service contract outreach. When an HVAC system's firmware falls three versions behind, it schedules an update window. Configuration drift triggers automatic reconciliation between recorded state and actual sensor data. This proactive visibility transforms installed base management from reactive firefighting to strategic asset planning.

Virtual models of deployed refrigerators and HVAC systems track real-time performance against expected baselines, flagging degradation before customer-impacting failures occur.

Estimates when compressors, motors, and heating elements will fail based on usage patterns and environmental conditions, enabling planned maintenance during off-hours.

Schedules preventive service based on actual equipment condition rather than arbitrary time intervals, reducing unnecessary service visits by 40%.

Appliance manufacturers face a unique installed base challenge: millions of units deployed across decades of product lines, each with different firmware versions, replacement parts, and expected lifespans. A refrigerator from 2010 shares no components with a 2025 model, yet both require lifecycle tracking. IoT-connected appliances generate telemetry streams, but legacy units remain invisible until they fail.

Thin margins make reactive service unsustainable. When a water heater fails unexpectedly, emergency dispatch costs eat the entire unit's profit margin. When HVAC systems reach end-of-life without proactive contract outreach, high-margin service revenue disappears to third-party providers. Complete asset visibility transforms these economics by shifting from reactive breaks-fixes to planned lifecycle management at scale.

Machine learning models assign confidence scores to each data source based on recency, consistency with service history, and telemetry correlation. When ERP shows a refrigerator at one firmware version but IoT telemetry reports another, the system trusts the telemetry and flags the ERP record for correction. Over time, the model learns which sources are most authoritative for each data type.

The platform infers asset state from service tickets, warranty claims, and installation records. For a legacy water heater without telemetry, the system tracks its install date, last service visit, typical failure patterns for that model year, and geographic factors. This probabilistic tracking flags high-risk units for proactive outreach even without live sensor data.

Most appliance manufacturers see measurable improvement within six months. The platform identifies units approaching warranty expiration or recommended service intervals, triggers automated outreach, and tracks conversion rates. Early pilots typically double contract attachment rates by reaching customers with lifecycle-appropriate offers rather than generic campaigns.

No. Bruviti integrates with existing systems through APIs and scheduled data exports. The platform acts as an intelligent overlay, enriching your current asset data rather than replacing it. You maintain existing workflows while gaining unified visibility and proactive lifecycle management capabilities.

Track three metrics: contract attachment rate increase, reduction in wrong-configuration service failures, and decrease in emergency service costs. Most appliance manufacturers see $1.5-2.5M annual margin improvement per 100,000 deployed units through a combination of higher contract renewal rates and lower reactive service expenses.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how Bruviti's platform transforms fragmented product data into proactive lifecycle management.

Schedule Demo