Fragmented asset records across warranty, IoT, and service systems prevent proactive maintenance and miss critical lifecycle opportunities.

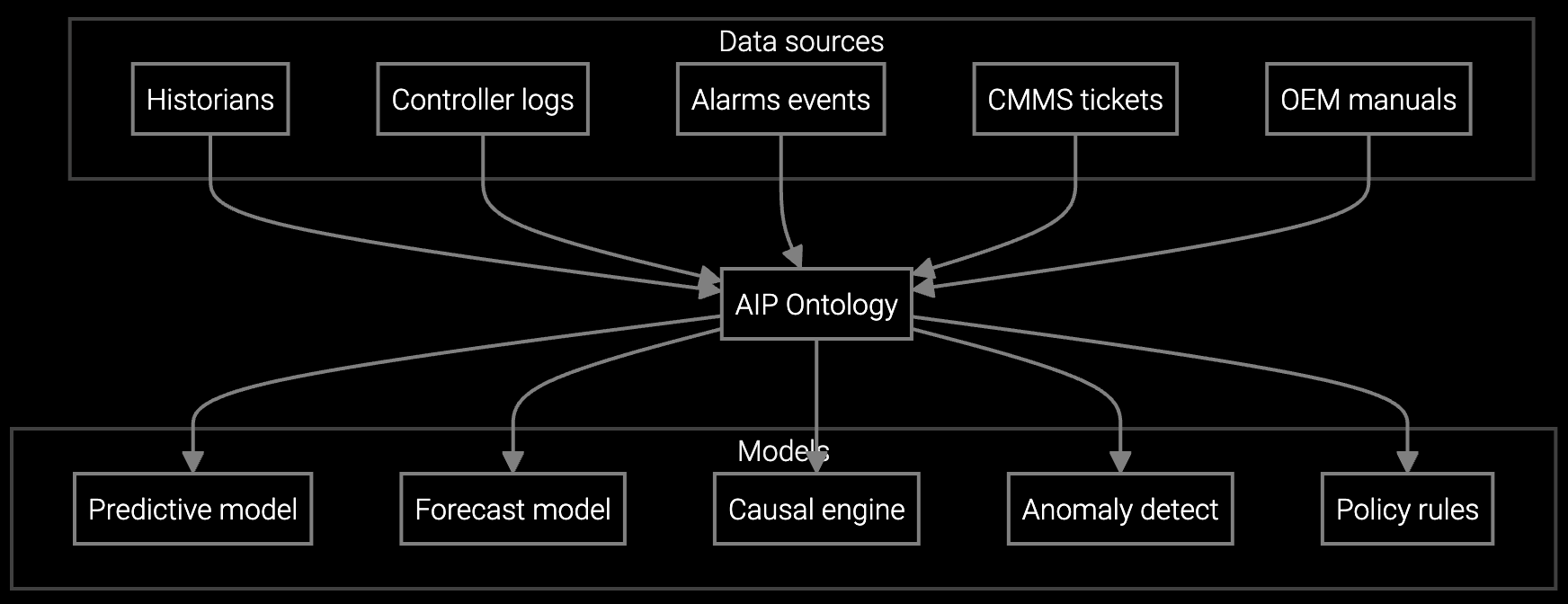

Incomplete asset data fragments across registration systems, service records, and IoT platforms. AI unifies serial numbers, configurations, and firmware versions into a single asset registry, enabling lifecycle visibility and proactive maintenance without vendor lock-in.

Appliances ship without warranty registration, leaving gaps in the installed base. When customers contact service, serial lookup fails, delaying entitlement verification and parts ordering.

Firmware updates and field modifications create discrepancies between recorded and actual configurations. Service teams troubleshoot based on outdated data, extending resolution time.

Incomplete lifecycle data prevents proactive contract renewal outreach. Extended warranties expire unnoticed, reducing recurring revenue and leaving customers unprotected during peak failure years.

Bruviti provides a headless asset management API that consolidates data from warranty systems, IoT telemetry feeds, and service records into a single source of truth. Python and TypeScript SDKs enable integration with SAP, Oracle, and custom data lakes without rewriting existing workflows.

The platform detects configuration drift by comparing recorded firmware versions against telemetry snapshots from connected appliances. When a mismatch is identified, the API triggers an update event, keeping lifecycle data accurate without manual audits. Custom lifecycle rules enable proactive alerts for end-of-support milestones, contract renewal windows, and upsell eligibility based on usage patterns.

Monitor IoT telemetry streams from refrigerators, HVAC systems, and washers to identify anomalies before field failures occur.

Estimate component lifespan based on usage patterns, enabling scheduled maintenance windows during low-demand periods.

Schedule preventive service based on actual appliance condition rather than fixed time intervals, reducing unnecessary visits.

Appliance manufacturers manage decades of deployed models—from commercial HVAC units installed in 2005 to IoT-enabled refrigerators shipped last quarter. Asset registry APIs aggregate data from legacy warranty systems, modern connected-device platforms, and field service records into a unified view.

For commercial kitchen equipment, telemetry from compressor sensors and control boards flows into the asset registry, enabling condition-based maintenance alerts. For consumer appliances, registration data captured at retail checkout links serial numbers to customer accounts, closing the visibility gap that delays warranty verification during service calls.

The platform applies configurable resolution rules prioritizing the most recent telemetry snapshot for configuration data, warranty system records for entitlement status, and service history for maintenance events. Conflicts are flagged in an exception queue for manual review when automated rules cannot determine the authoritative source.

Yes. For legacy models without IoT capability, the API ingests data from service call records, warranty claims, and manual registration forms. While telemetry-based configuration drift detection is unavailable, serial number tracking and lifecycle milestone alerts still function through timestamp-based rules.

All asset data remains accessible via standard API export endpoints in JSON or CSV format. The platform does not encrypt or obfuscate data in proprietary formats, ensuring you retain full ownership and portability. Python SDKs include export utilities for bulk data migration to alternative systems.

IoT telemetry payloads include firmware version fields that are automatically compared against the asset registry on each connection event. Discrepancies trigger configuration drift alerts, and the registry updates to reflect the current state. Custom rules can flag devices running outdated firmware for targeted upgrade campaigns.

Initial integration typically requires 4-6 weeks for API endpoint configuration, data mapping, and pilot testing. Python and TypeScript SDKs provide pre-built connectors for SAP, Oracle, and Salesforce. Custom data lakes require additional mapping logic but avoid full system rewrites through the headless API architecture.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

Explore API documentation and Python SDK examples for unified lifecycle visibility.

Schedule Technical Demo