Returns processing costs spike when 20-35% of warranty claims show no defect, eroding reserve accuracy and delaying valid customer replacements.

High NFF rates stem from symptom-based diagnostics without equipment data. AI vision models analyze returned product images to validate defects before RMA approval, reducing unnecessary returns by 40-60% while maintaining customer trust through transparent validation workflows.

Finance teams provision warranty reserves based on historical claim rates, but unpredictable NFF spikes destroy forecast accuracy. When 25% of refrigerator returns show no compressor defect, reserve models fail and quarterly accruals swing wildly.

Each unnecessary return triggers freight, receiving inspection, refurbishment evaluation, and restocking workflows. For a $600 dishwasher, processing a NFF return costs $120-180 in pure logistics before determining no defect exists.

Overly aggressive RMA denials to reduce NFF rates backfire when legitimate defects get rejected. Customers post photos of failed HVAC heat exchangers that were denied warranty, destroying brand reputation and triggering escalations to executive offices.

The root cause of high NFF rates is approving returns based on customer symptom descriptions without objective defect evidence. A customer reports "washer not spinning" but the actual cause could be user error (unbalanced load), environmental factors (circuit breaker), or a genuine motor failure. Traditional RMA systems lack the data to distinguish these scenarios before authorizing a costly return.

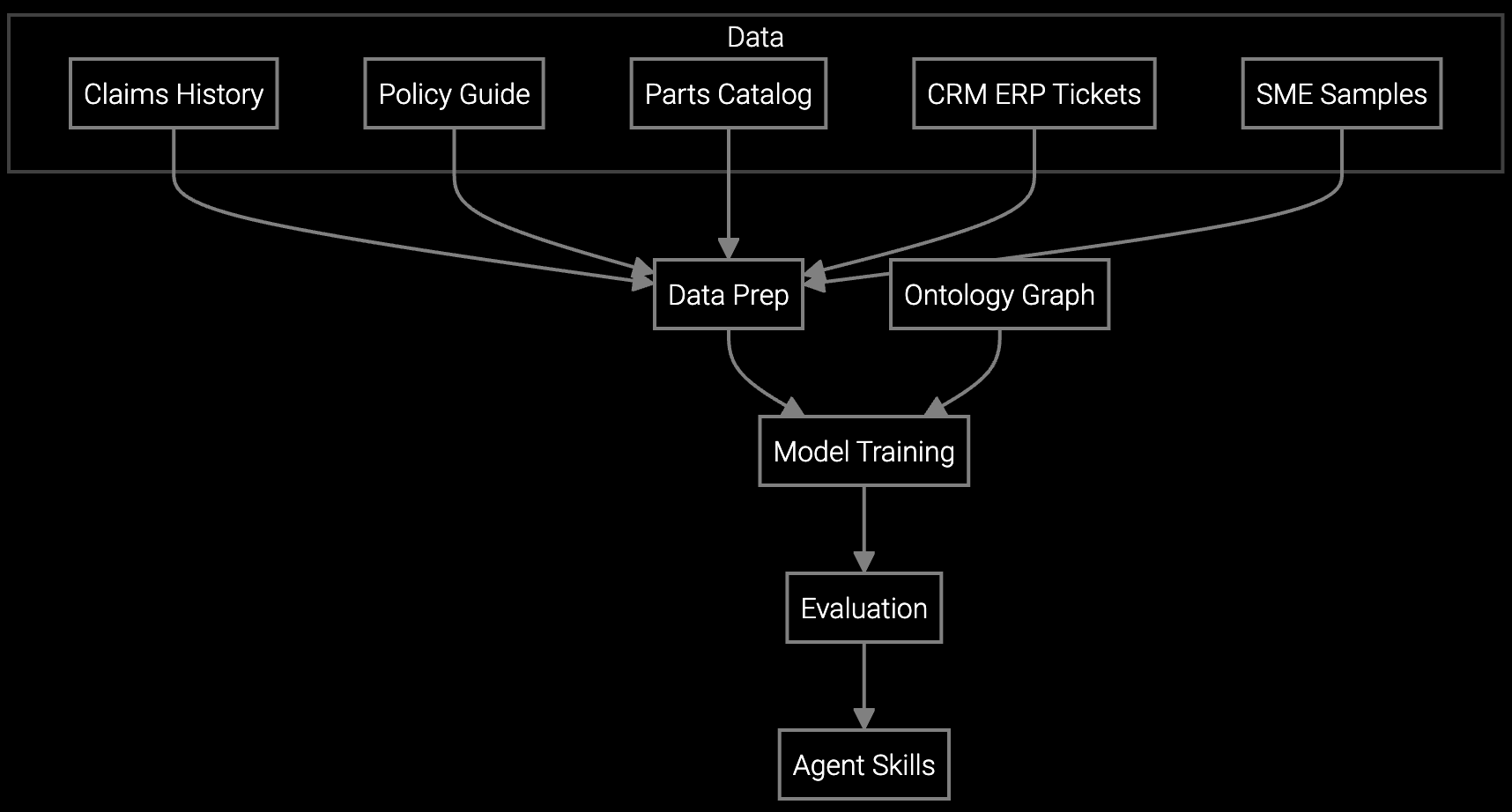

Bruviti's platform integrates computer vision APIs directly into the claims workflow. Before issuing an RMA, the system requests photos or videos of the claimed defect—rust on a refrigerator door seal, cracks in a microwave magnetron, discoloration on a heat pump coil. Vision models trained on millions of warranty images classify defect type, severity, and root cause. For connected appliances, the platform correlates image evidence with telemetry logs to validate failure mode. Builders control the validation rules via Python SDKs, defining which defect types require visual evidence and which confidence thresholds trigger auto-approval versus manual review.

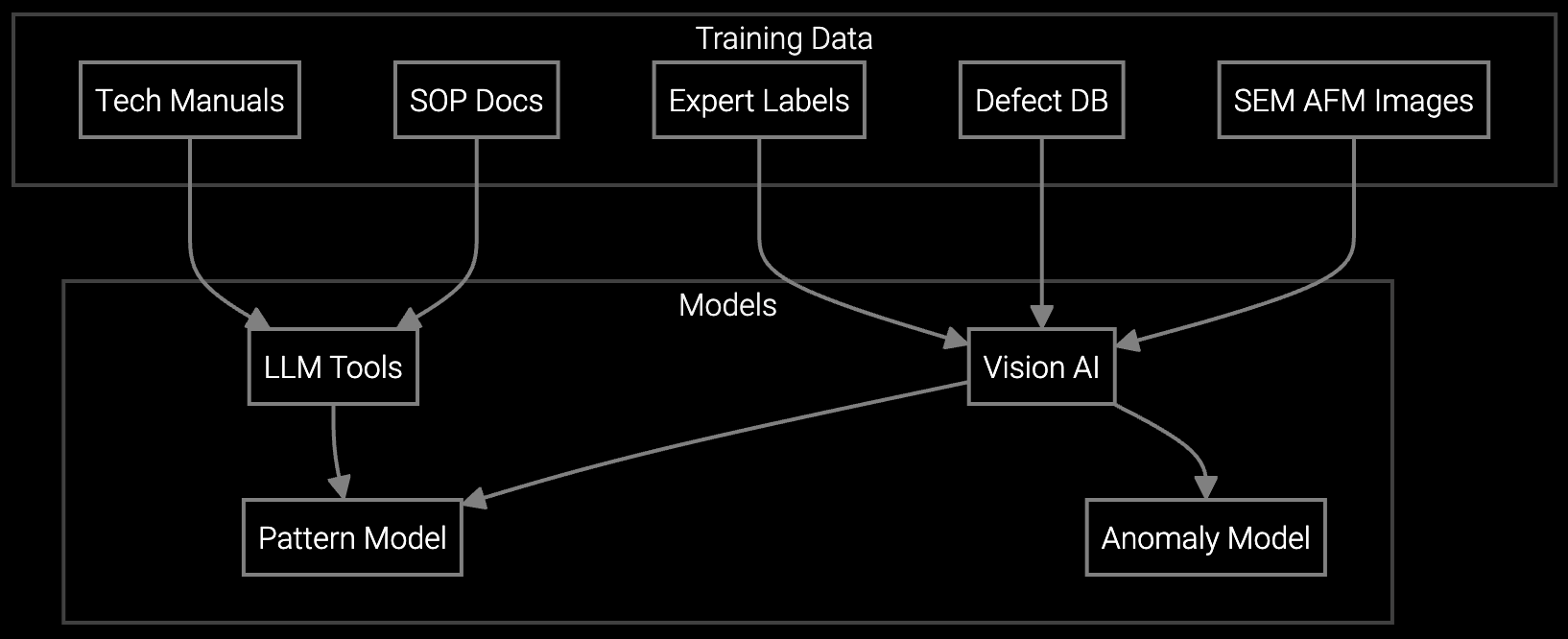

Analyze microscopic images of appliance component failures to identify defect signatures, classify failure modes, and validate warranty claims with precision unavailable to manual inspection.

Automatically classify appliance warranty claims by defect type, affected component, and root cause category, reducing manual processing time and improving fraud detection accuracy.

Appliance manufacturers face warranty spikes during peak seasons—HVAC claims surge during summer heat waves, refrigerator failures spike during holiday usage, dishwasher returns jump in January post-holiday stress tests. Traditional RMA workflows can't scale validation capacity fast enough, leading to blanket approvals that balloon NFF rates to 30%+ during peak months.

Vision-based validation scales instantly because image analysis throughput isn't constrained by headcount. During a July heat wave, when AC compressor claims triple, the platform processes 500 image-based validations per hour versus 40 manual reviews. For connected appliances with IoT telemetry, the system cross-references claimed symptoms with actual sensor logs—if a customer reports "refrigerator not cooling" but temperature logs show consistent 37°F operation, the RMA gets flagged for troubleshooting before approval.

The validation workflow is designed for transparency, not gatekeeping. When requesting defect photos, the system explains why visual evidence accelerates approval for legitimate claims and includes example photos showing the type of evidence needed. For confirmed defects, the platform auto-approves RMAs in under 2 minutes versus 24-48 hours for manual review. Customers with genuine failures get faster service, not more friction. For edge cases where photos aren't feasible, the system defaults to traditional troubleshooting paths.

Foundation models trained on warranty image datasets achieve 85-92% accuracy on common failure modes like refrigerator seal damage, dishwasher spray arm clogs, HVAC coil corrosion, and washer drum imbalance. Accuracy improves to 94-97% when models fine-tune on an OEM's specific product images for 30-60 days. The platform flags low-confidence classifications for human review rather than auto-rejecting, maintaining customer trust while capturing learning data to improve model performance.

Yes. Bruviti provides Python SDKs for model fine-tuning using your labeled warranty images and defect classification schema. You control training data pipelines, model versioning, and deployment to production endpoints. The platform supports both supervised learning on historical claims and active learning where the model requests labels on ambiguous images to improve classification boundaries. All training happens in your infrastructure if data sovereignty is required, or on Bruviti-managed infrastructure with encryption at rest.

Vision models detect fraud patterns invisible to manual review—lighting inconsistencies suggesting staged photos, metadata mismatches between claimed failure date and image timestamp, defect signatures matching intentional damage rather than wear. The system flags suspicious claims for investigator review rather than auto-rejecting, providing visual evidence and anomaly scores to support fraud determination. For appliance OEMs, this catches $50K-200K annually in fraudulent claims while avoiding false accusations that damage customer relationships.

Not all failures produce visible evidence—intermittent electrical faults, software glitches on smart appliances, or internal component failures invisible without disassembly. For these scenarios, the platform supplements image validation with telemetry analysis for connected products or structured troubleshooting flows that collect diagnostic data (error codes, cycle logs, voltage readings). The validation logic is configurable per defect type, requiring visual evidence only where it reliably identifies root cause. This prevents false denials while still catching the 60-70% of NFF returns caused by user error or environmental factors.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how Bruviti's platform integrates defect detection into your RMA workflow without disrupting customer experience.

Talk to an Expert