Missing serial numbers and configuration gaps delay PM cycles and obscure equipment health across your installed base.

Fix incomplete asset data by connecting telemetry streams to auto-populate serial numbers, configurations, and firmware versions. AI validates records against actual fab equipment state, eliminating manual data entry and configuration drift across your installed base.

Legacy equipment lacks serial number tracking in modern systems. You can't correlate failure patterns or verify warranty status without manually checking each tool.

Recipe changes and chamber kit replacements don't update your asset registry. Actual equipment state diverges from system records, breaking predictive maintenance.

You don't know which tools are approaching EOL or due for upgrades. Firmware status is unknown until something breaks during a production run.

Connect your equipment telemetry directly to the asset registry. The platform ingests SECS/GEM messages, recipe files, and EDA logs to auto-populate serial numbers, firmware versions, and chamber configurations. No more manual spreadsheet updates or data entry swivel-chair work.

AI validates registry records against actual equipment state every hour. Configuration changes trigger automatic updates. Firmware mismatches appear in your dashboard the moment they occur. You see the complete installed base at a glance—no guessing, no stale data, no missing pieces.

Virtual models of lithography and etch tools track real-time performance, enabling proactive chamber PM before wafer yield drops.

Continuously monitors process sensor readings for deposition and CMP tools, alerting when chamber temperature or pressure deviates from recipe specs.

Schedules chamber kit replacements and preventive maintenance based on actual tool usage and process hours, not fixed calendar intervals.

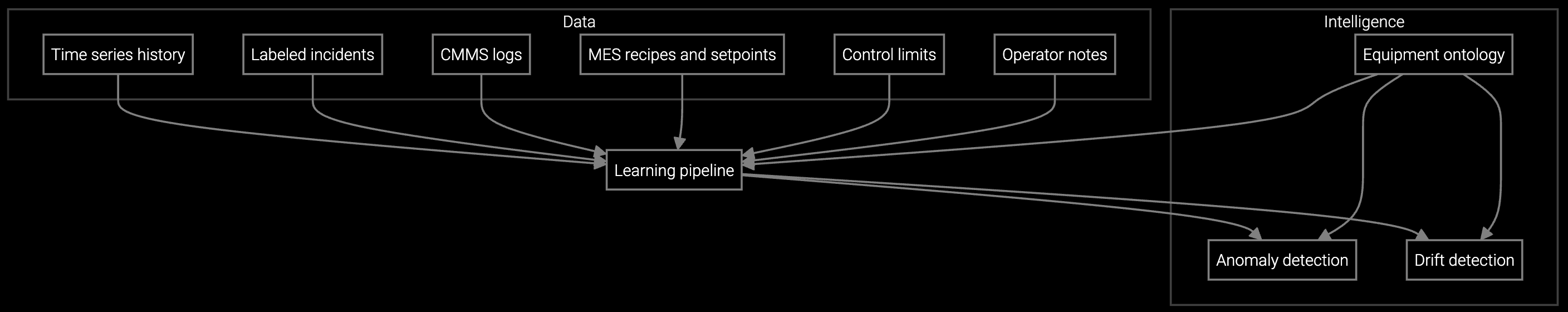

Semiconductor fabs run hundreds of tools across lithography, etch, deposition, CMP, and metrology. Each tool has dozens of subsystems generating telemetry streams. The platform ingests SECS/GEM messages, FDC data, and EDA logs to build a unified asset view without touching your existing fab automation infrastructure.

Recipe changes happen constantly as process engineers tune parameters for yield optimization. Chamber kits wear out based on wafer count, not calendar time. The system tracks actual process hours and consumable usage per tool, auto-updating asset records as configurations evolve. You see which etch chambers need PM next week and which lithography tools are still on outdated firmware—all in one screen.

Yes. The platform can ingest manual CSV uploads, work order system logs, or PM completion records to populate asset data for older tools. AI extracts serial numbers and configurations from unstructured sources like PDF service reports. You won't have real-time sync, but you'll eliminate the data gaps.

The platform compares telemetry signatures against registry records every hour. Recipe parameter changes, firmware updates, and chamber kit replacements all generate distinct telemetry patterns. When observed behavior doesn't match the recorded configuration, the system flags the drift and suggests the likely change based on historical patterns.

Asset records follow the serial number. When a tool reconnects from a new location, the platform detects the change and prompts you to confirm the move. For refurbished equipment, you can reset the usage counters while preserving the failure history so predictive models still work.

No. The platform syncs with multiple systems simultaneously—ERP, CMMS, MES, and custom databases. It acts as the single source of truth by reconciling data across systems. You'll still use your existing tools; they just all reference the same accurate asset records now.

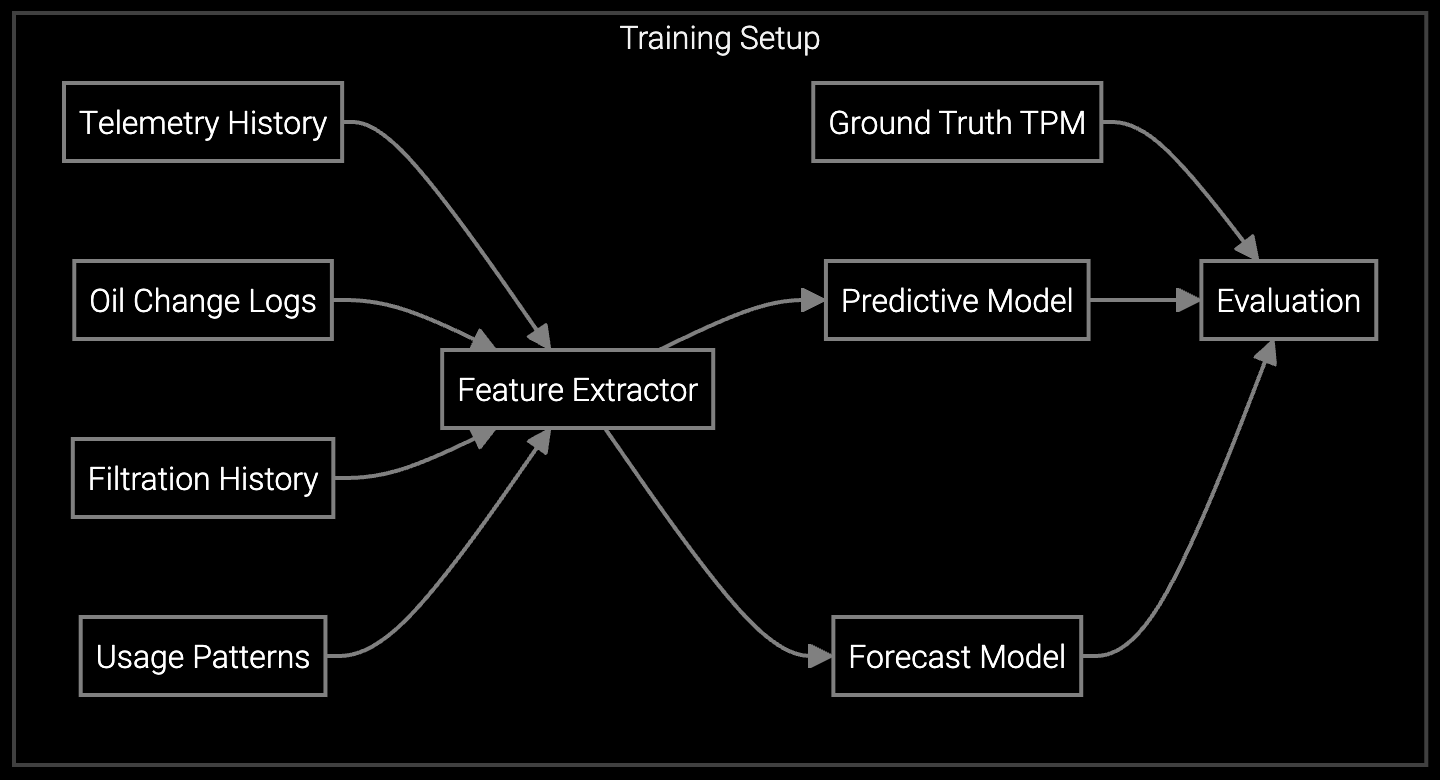

Most fabs see registry accuracy above 90% within 30 days of connecting telemetry streams. Predictive maintenance models need 60-90 days of clean data to train effectively. You can start with rule-based alerts immediately while the AI learns your equipment patterns.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how automated asset registry sync eliminates manual updates and gives you complete lifecycle visibility.

Schedule Demo