Missing serial numbers and configuration gaps create service delays when you can't identify what's actually running in the field.

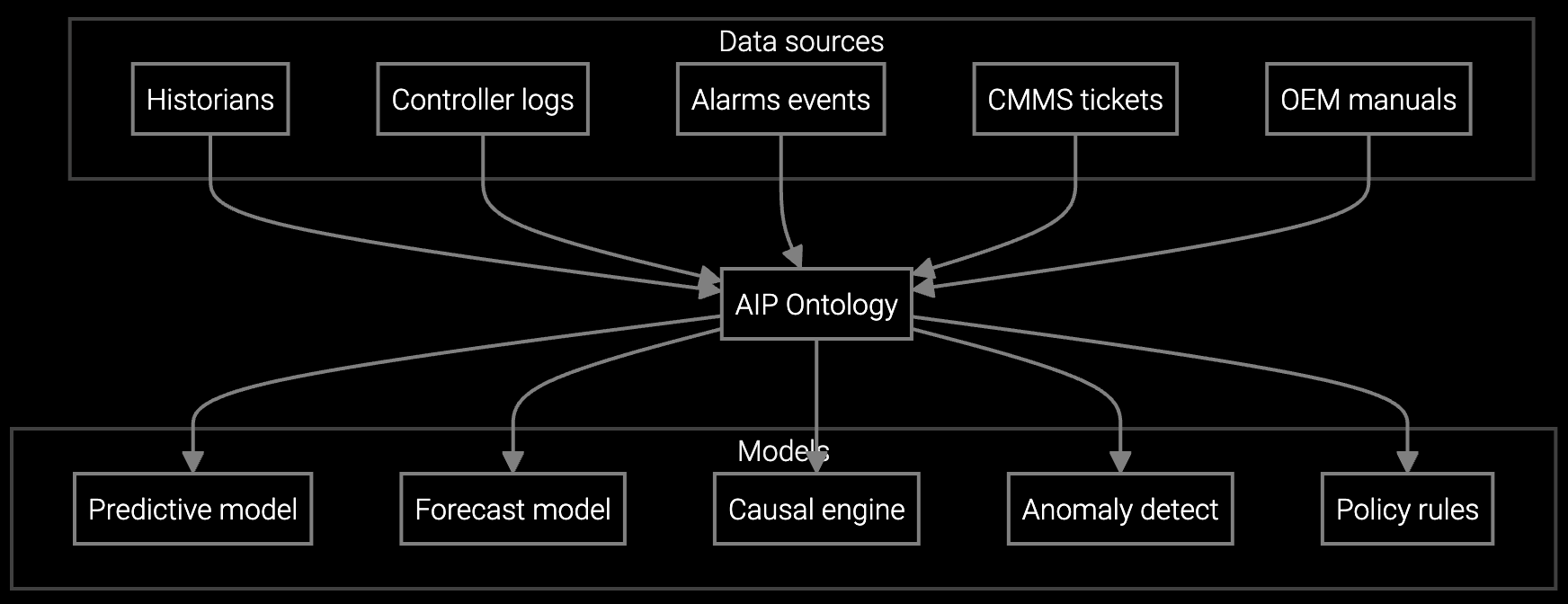

Incomplete asset data creates blind spots in equipment tracking. AI reconciles serial numbers, configurations, and telemetry from PLCs, SCADA systems, and legacy databases into a unified asset registry, eliminating manual data hunts.

Customer calls about a compressor failure. You can't find the asset record because the serial number was never logged. Manual cross-reference through shipping records, invoices, and install logs takes hours.

System records show original configuration from install. Actual equipment has different firmware, added sensors, and replaced modules. You discover the mismatch only when troubleshooting fails.

Equipment installed before the current ERP system went live exists in paper records or disconnected spreadsheets. Each lookup requires switching between four different data sources with no guarantee of finding what you need.

The platform automatically reconciles asset data from multiple sources into a single view. When a customer calls, you see complete equipment history, current configuration, and telemetry status in one screen. No more hunting through legacy databases or guessing at firmware versions.

AI identifies configuration drift by comparing system records against real-time telemetry from PLCs and SCADA feeds. You get alerts when actual state diverges from documented configuration, preventing troubleshooting dead ends. Asset registry stays current without manual data entry.

Virtual models of CNC machines and industrial robots track real-time performance against baseline configurations, catching drift before it causes failures.

Analyzes PLC and SCADA telemetry from pumps and compressors to identify anomalies, automatically linking detected issues to asset records.

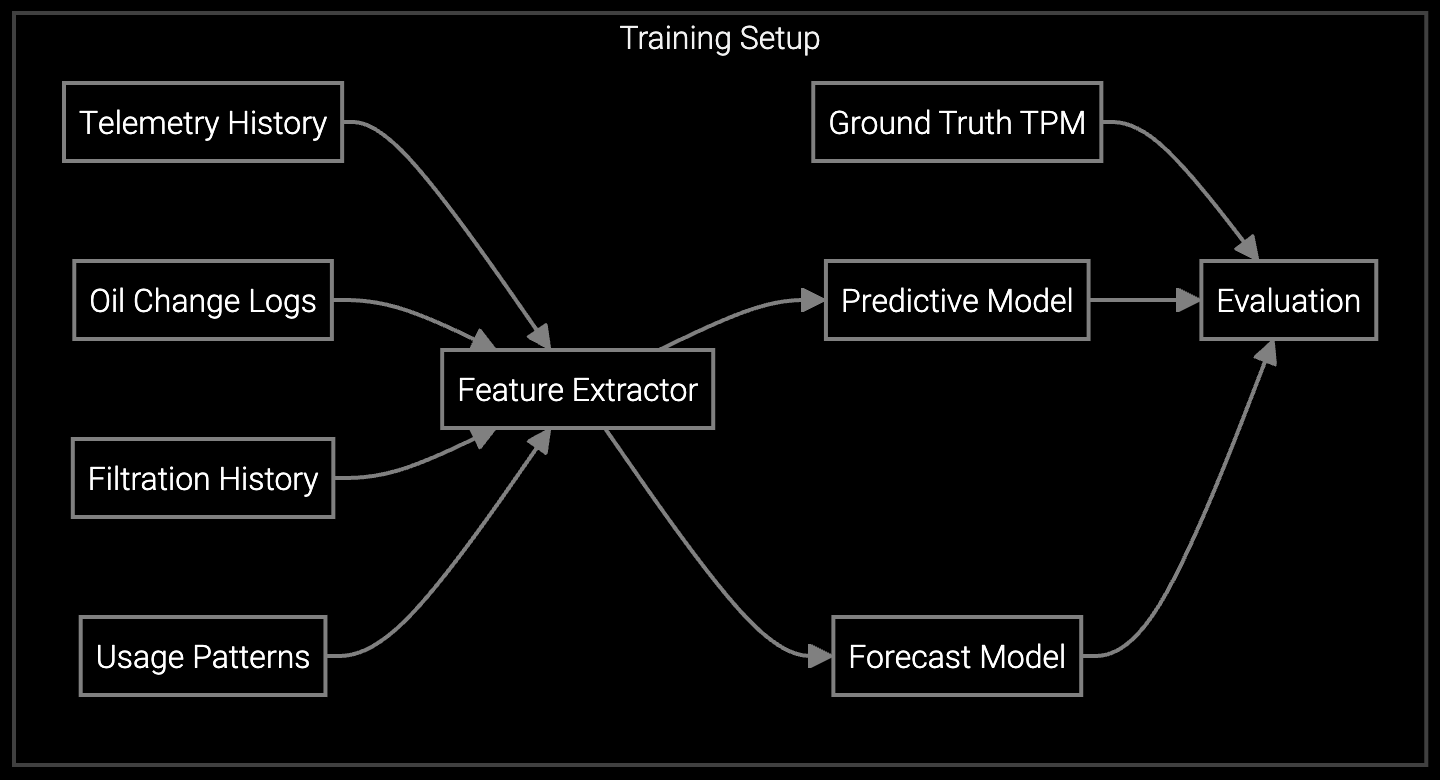

Estimates when components will fail based on actual usage patterns and sensor data, enabling planned maintenance windows instead of emergency repairs.

Industrial equipment manufacturers face 10-30 year lifecycles where machines undergo countless field modifications. A CNC machine sold in 2005 may now have different spindle motors, upgraded control boards, and added sensors that never made it back to your records. When that machine breaks, incomplete data forces service teams to troubleshoot blind.

Legacy systems compound the problem. Equipment installed before your current ERP exists in disconnected spreadsheets, paper records, or retired databases. Each customer call becomes a data archaeology project across multiple systems with no guarantee you'll find complete information.

AI matches equipment using multiple identifiers including model numbers, install dates, customer location, and telemetry signatures. When PLC data shows a specific controller type at a known site, the platform probabilistically links it to the correct asset record even if the serial number is missing. Manual verification confirms high-probability matches.

Real-time telemetry comparison detects undocumented changes automatically. When a sensor reading shows a different firmware version or added module, the system flags configuration drift and prompts record update. This catches field modifications within 24 hours instead of discovering them months later during troubleshooting.

For non-connected equipment, the platform consolidates manual updates from service visits, warranty claims, and parts orders into the unified registry. While you lose automatic drift detection, you still eliminate the multi-system lookup problem by centralizing all available data in one view.

AI-assisted data migration extracts asset information from old databases, spreadsheets, and scanned documents. The platform maps legacy identifiers to current records, flags ambiguous matches for manual review, and builds a complete asset timeline even when source systems are no longer accessible.

The system creates a drift alert with specific discrepancies highlighted. You review the detected changes, verify with the customer if needed, and approve the record update. This transforms unknown field state into documented configuration in minutes instead of weeks of investigation.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

Stop hunting through legacy systems. Get instant access to complete equipment history, current configuration, and real-time telemetry status.

Schedule Demo