When lithography tool configs diverge from asset records, $1M/hour downtime becomes untraceable.

Configuration drift occurs when recorded equipment states diverge from actual fab conditions. Automated telemetry reconciliation detects mismatches in real-time, triggering sync workflows that maintain asset accuracy without manual audits.

Asset databases show chamber kits installed six months ago, but the actual tool was reconfigured three times since then. Process engineers trust stale data when diagnosing yield issues.

Legacy tools lack systematic serial tracking. When a defect surfaces, tracing back to the specific deposition chamber or FOUP handler becomes archaeology, not analytics.

Tool controllers run different firmware versions than asset records indicate. Recipe optimization efforts fail because baseline assumptions about tool behavior are wrong.

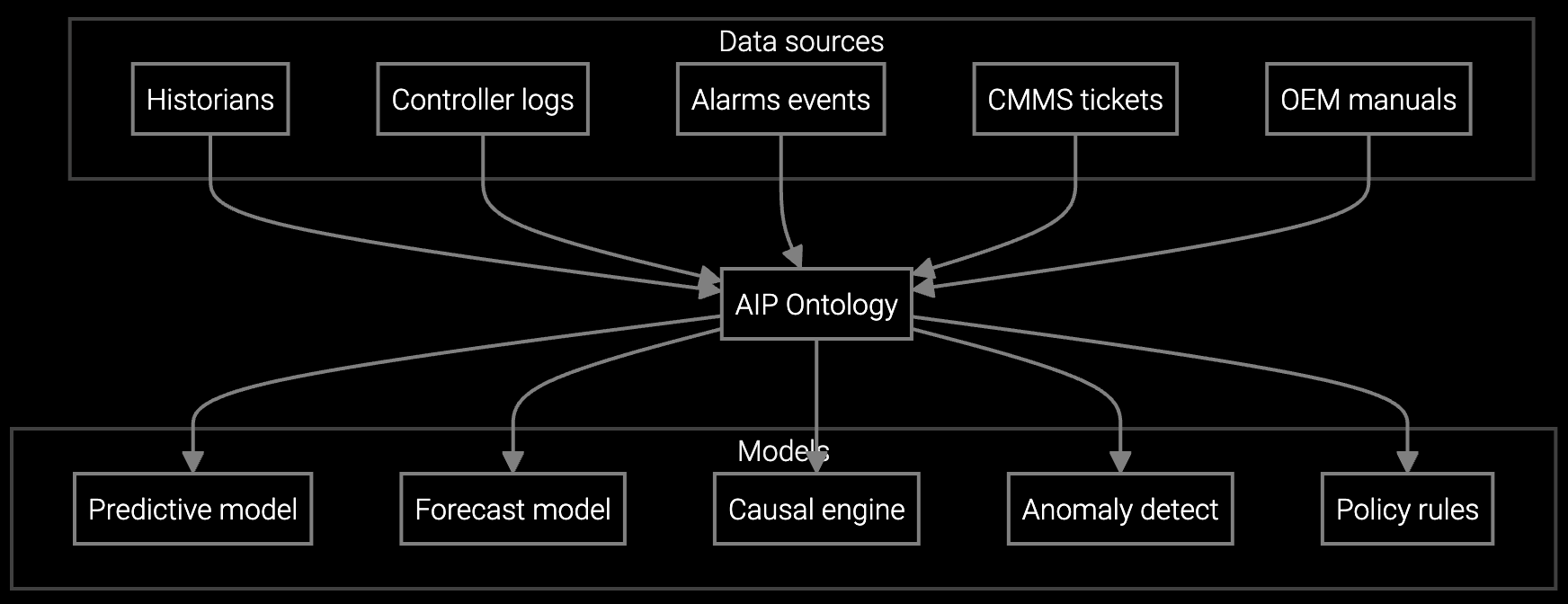

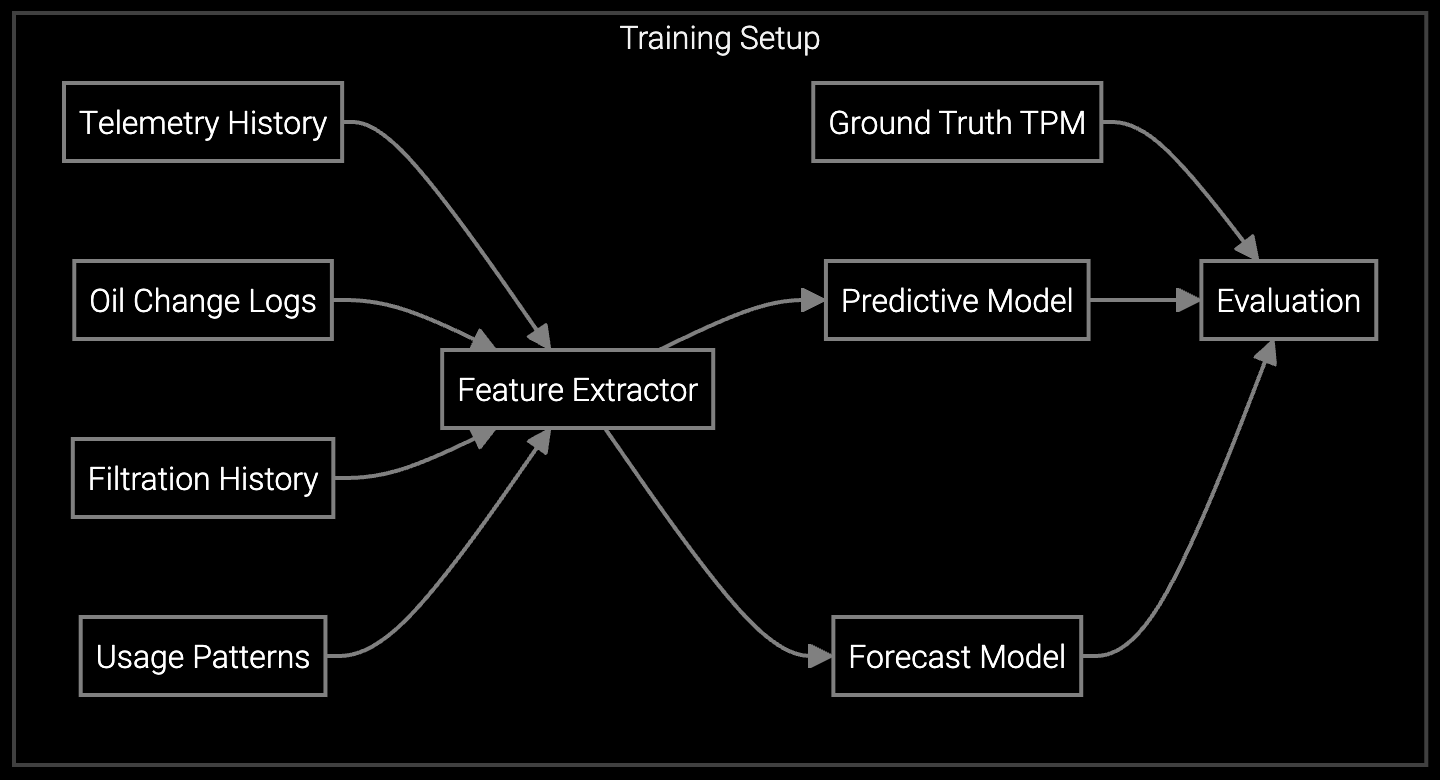

The platform ingests telemetry from SECS/GEM interfaces, FDC systems, and MES databases to build a real-time asset state graph. When tool sensor data contradicts asset records—chamber part IDs, recipe versions, consumable installation dates—the reconciliation engine flags the mismatch and triggers configurable sync workflows.

Developers use Python SDKs to define custom reconciliation rules per tool type. The headless architecture exposes RESTful endpoints for asset queries, allowing you to integrate asset truth into existing dashboards, PM scheduling systems, or yield correlation tools without rearchitecting your stack. You own the reconciliation logic, not a black box vendor model.

Analyze SECS/GEM telemetry streams to identify when tool sensor readings indicate configuration states that contradict asset records, triggering automated reconciliation.

Virtual equipment models continuously sync with actual tool states, exposing configuration drift before process engineers base yield decisions on phantom data.

Trace yield defects back to specific chamber configurations and firmware versions using accurate asset lineage, eliminating guesswork in root cause analysis.

Semiconductor fabs operate hundreds of lithography, etch, and deposition tools, each with dozens of configurable sub-components. A single EUV scanner has 40+ chamber parts, multiple recipe versions, and firmware that changes monthly. Configuration drift isn't just an inconvenience—it's a direct threat to yield when process assumptions rest on outdated asset data.

The platform's asset graph models these hierarchies natively. Tool-to-chamber-to-consumable relationships are captured from SECS/GEM streams, not manually entered spreadsheets. When a chamber kit swap happens but the asset database isn't updated, telemetry reconciliation catches it within minutes, not weeks later during a yield excursion investigation.

The platform continuously compares tool sensor data (chamber part IDs, firmware versions, recipe timestamps) from SECS/GEM streams against asset database records. When mismatches exceed configured thresholds, automated alerts trigger sync workflows. This eliminates periodic manual audits and reduces detection lag from weeks to minutes.

Yes. The Python SDK allows you to define tool-specific reconciliation logic. For example, lithography tools might trigger alerts on recipe version mismatches, while etch tools focus on chamber part serial number drift. Rules are version-controlled code, not buried in vendor UIs.

The reconciliation engine flags both sources and presents the conflict to designated reviewers via configurable notification channels. You define the resolution logic: trust telemetry by default, escalate to process engineers for specific tool types, or auto-sync based on timestamp priority. The platform doesn't impose a single truth hierarchy.

The platform exposes RESTful asset query endpoints that return configuration state, drift history, and confidence scores. You can call these APIs from Tableau, Power BI, or custom dashboards built on React or Vue. Response times average under 200ms, supporting real-time visualizations without caching layers.

Accurate asset records directly improve yield investigations. When process engineers diagnose defects, they need to know the actual chamber config, firmware version, and consumable age at the time wafers were processed. Configuration drift obscures this ground truth, leading to false root cause conclusions. Eliminating drift accelerates correct diagnosis, which shortens time-to-fix and reduces repeat defects.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how API-driven reconciliation eliminates configuration drift without rebuilding your asset database.

Talk to Engineering