Hyperscale customers demand proactive service—incomplete asset visibility costs you contract renewals.

Start with BMC telemetry integration to track server configurations and predict failures. Connect existing asset databases via API, prioritize high-value hyperscale accounts, and measure success through configuration accuracy and contract attachment rates within 90 days.

Missing serial numbers and firmware versions prevent proactive lifecycle management. Hyperscale operators track thousands of servers—your asset database can't match their scale or accuracy.

Deployed configurations diverge from your records as customers update firmware, swap components, and expand capacity. You discover drift only when failures occur—too late for prevention.

Without lifecycle visibility, you can't identify upgrade candidates or EOL equipment nearing support expiration. Competitors proactively reach your customers first.

Implementation starts with telemetry integration, not database migration. Connect BMC and IPMI data streams from deployed servers to create a real-time asset registry. The platform ingests hardware health metrics, firmware versions, and configuration changes automatically—no manual inventory updates required.

Prioritize hyperscale accounts where proactive failure prediction delivers immediate value. Target equipment cohorts with high failure rates or EOL timelines to demonstrate ROI quickly. Use API connectors to link existing CRM and ERP systems, preserving your current workflows while adding predictive intelligence. This phased approach reduces risk and delivers measurable outcomes in the first 90 days.

Analyze BMC telemetry streams from hyperscale deployments to identify server anomalies and predict power supply failures before downtime occurs.

Estimate when storage drives and DIMMs will fail based on usage patterns, enabling scheduled maintenance during planned downtime windows.

Schedule cooling system and UPS maintenance based on actual equipment condition rather than fixed intervals, reducing service costs.

Data center OEMs manage asset inventories spanning millions of servers across geographically distributed facilities. Hyperscale operators deploy homogeneous server cohorts—thousands of identical configurations—making pattern recognition highly effective. Your customers track PUE metrics, thermal zones, and power distribution at granular levels.

Implementation leverages existing BMC and IPMI infrastructure already deployed in every rack. The platform ingests telemetry without additional sensors or hardware changes. Start with compute nodes in high-density pods where thermal issues drive failure rates, then expand to storage arrays and cooling infrastructure once initial ROI is proven.

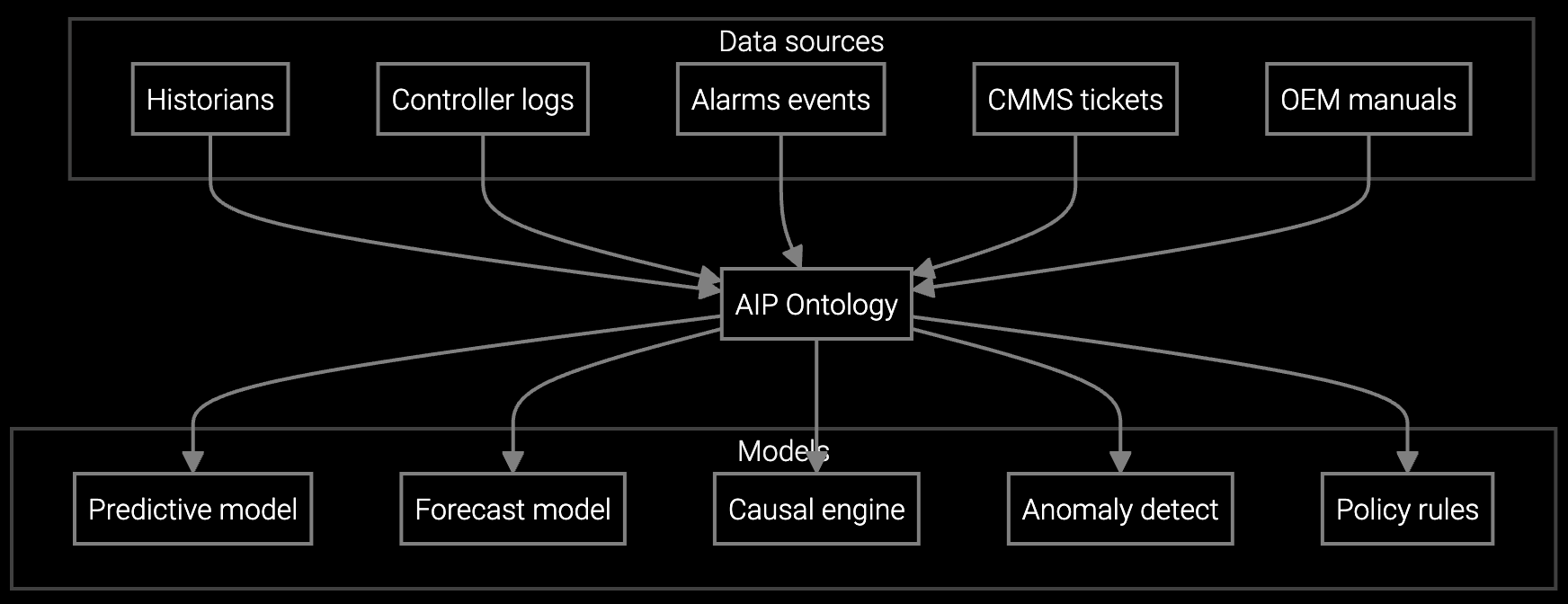

The platform ingests BMC telemetry via IPMI or Redfish APIs, capturing hardware health metrics, firmware versions, and configuration states. It also connects to existing asset databases and CRM systems via REST APIs to enrich lifecycle tracking with contract and entitlement data.

Initial implementation completes in 90 days. The first 30 days focus on telemetry integration and model training using historical data. Days 31-60 involve pilot deployment with a single hyperscale account. Days 61-90 expand coverage and measure improvements in configuration accuracy and contract attachment rates.

Prioritize compute nodes in high-density pods where thermal issues and component failures are most common. These deployments have the highest failure rates and the clearest ROI from predictive maintenance. Expand to storage arrays and cooling infrastructure once initial success is proven.

The platform continuously compares live BMC telemetry against registered configurations, flagging discrepancies in real time. When customers swap components, update firmware, or expand capacity, these changes are detected automatically and your asset database is updated without manual intervention.

Track configuration accuracy rate, contract attachment rate, and time-to-detect for asset discrepancies. Secondary metrics include predictive maintenance hit rate and reduction in emergency service calls. These KPIs demonstrate both operational efficiency and revenue impact within the first 90 days.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

Discover how Bruviti helps data center OEMs achieve 67% configuration accuracy improvement in 90 days.

Schedule Implementation Review