Configuration drift and incomplete asset data cost fabs millions in unplanned downtime—implementation roadmap matters.

Implement in phases: start with high-value tool populations for asset visibility, integrate with ERP and MES for configuration tracking, then layer predictive models on telemetry data. Three-to-six month deployment yields 40% improvement in asset data accuracy and 25% increase in contract attachment rates.

Missing serial numbers and configuration records for legacy lithography and etch tools prevent proactive lifecycle planning. ERP systems show purchase dates but not actual field configurations or usage patterns.

Actual tool configurations diverge from system records as fabs modify recipes, upgrade chamber components, and change consumables. Service teams arrive on-site with wrong parts or outdated procedures.

Service contracts expire unnoticed because OEMs lack visibility into equipment reaching end-of-warranty windows. No systematic tracking of contract expiration dates tied to actual equipment usage patterns.

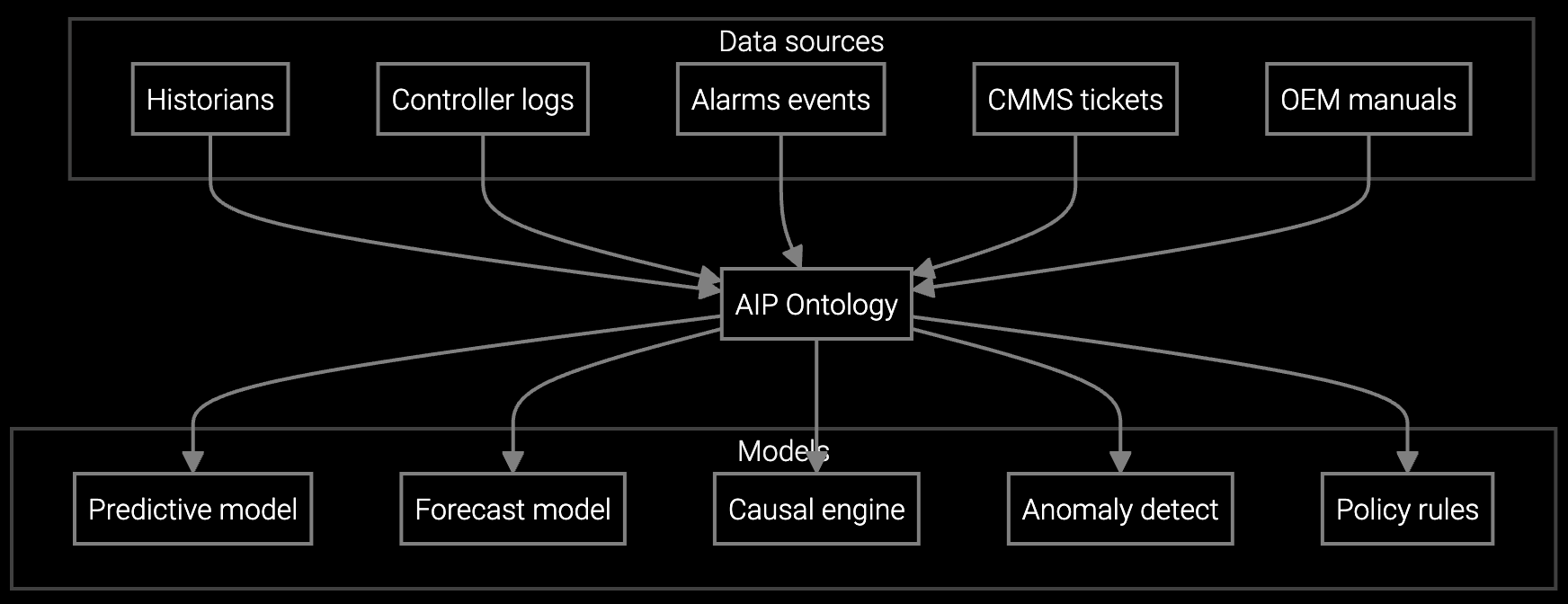

Bruviti's platform deploys in three implementation phases tailored for semiconductor OEMs. Phase one establishes asset registry foundations by ingesting existing ERP data, MES logs, and manual records to create a unified equipment database. The platform reconciles conflicting records, flags missing serial numbers, and identifies configuration gaps across tool populations.

Phase two integrates real-time telemetry from fab equipment—lithography systems, etch tools, deposition chambers—to track actual configurations versus system records. The AI learns equipment signatures from sensor patterns and process parameters, automatically detecting configuration drift when tools deviate from documented baselines. Phase three layers predictive lifecycle models that analyze usage patterns, maintenance history, and failure telemetry to forecast contract renewal opportunities, EOL/EOS windows, and upgrade candidates.

Ingests telemetry from lithography, etch, and deposition tools to identify configuration anomalies and predict failures before they trigger fab downtime.

Analyzes usage patterns and process hours to forecast when chamber components and consumables require replacement, enabling proactive contract renewal outreach.

Schedules preventive maintenance based on actual equipment condition and fab production schedules rather than fixed calendar intervals, reducing unplanned downtime.

Semiconductor fabs operate hundreds of high-value tools—EUV lithography systems, plasma etch chambers, chemical vapor deposition reactors—each generating thousands of sensor readings per second. Implementation begins with telemetry integration from SECS/GEM interfaces and MES systems that already track process recipes and equipment states.

The platform normalizes data across tool vendors—Applied Materials, Lam Research, ASML, Tokyo Electron—that use different data formats and communication protocols. Asset tracking starts with critical tool populations where downtime costs exceed $1M per hour, then expands to metrology equipment, gas delivery systems, and wafer handling automation as the deployment matures.

Phase one requires data access from ERP, MES, and existing service systems—typically two weeks of IT integration work. Phase two telemetry integration needs equipment data feed configuration, handled by controls engineers already managing SECS/GEM connections. No dedicated headcount beyond existing service operations and IT staff.

Asset registry reconciliation completes within 30 days of data ingestion, immediately surfacing missing serial numbers and configuration gaps. Configuration drift detection begins producing actionable alerts within 60 days as the AI establishes equipment baselines from telemetry patterns. Full contract attachment rate improvement materializes by month four when renewal opportunity identification becomes systematic.

Yes. The platform normalizes data from Applied Materials, Lam, ASML, TEL, and other vendors regardless of equipment vintage or communication protocol. Legacy tools lacking modern telemetry still benefit from registry reconciliation and manual configuration tracking. The system integrates with SECS/GEM, OPC-UA, and proprietary vendor interfaces without requiring equipment modifications.

Primary risk is data quality in existing ERP and MES systems—incomplete records require manual cleanup before AI models deliver value. Telemetry integration timing must align with fab maintenance windows to avoid production disruption. Organizations underestimate change management effort required to shift service teams from reactive parts ordering to proactive lifecycle planning based on AI recommendations.

The platform enhances existing contract management by identifying equipment approaching warranty expiration or contract renewal windows. It does not modify contract terms or warranties. Service teams gain visibility into which tools lack coverage, enabling proactive renewal outreach before customers experience post-warranty service sticker shock. Contract attachment rate improvements directly increase recurring revenue without changing contract structure.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how Bruviti's phased deployment approach delivers measurable asset visibility improvements in 90 days.

Schedule Implementation Review