Every unnecessary RMA drains warranty reserves and clogs your refurbishment pipeline.

High NFF rates drain warranty budgets. AI-assisted diagnostics verify failures before return authorization, matching claim symptoms against equipment telemetry and historical failure patterns to eliminate unnecessary RMAs.

Equipment returned under warranty arrives at refurbishment centers with no detectable fault. Reverse logistics, inspection, and restocking costs accumulate for returns that never should have been authorized.

NFF returns consume inspection capacity that should be devoted to genuine failures. Queue times stretch as your team processes equipment that could have stayed in the field, delaying real repairs.

Unpredictable NFF volume makes warranty cost forecasting unreliable. Finance accrues reserves based on historical claims, but invalid returns inflate those numbers beyond actual equipment failure rates.

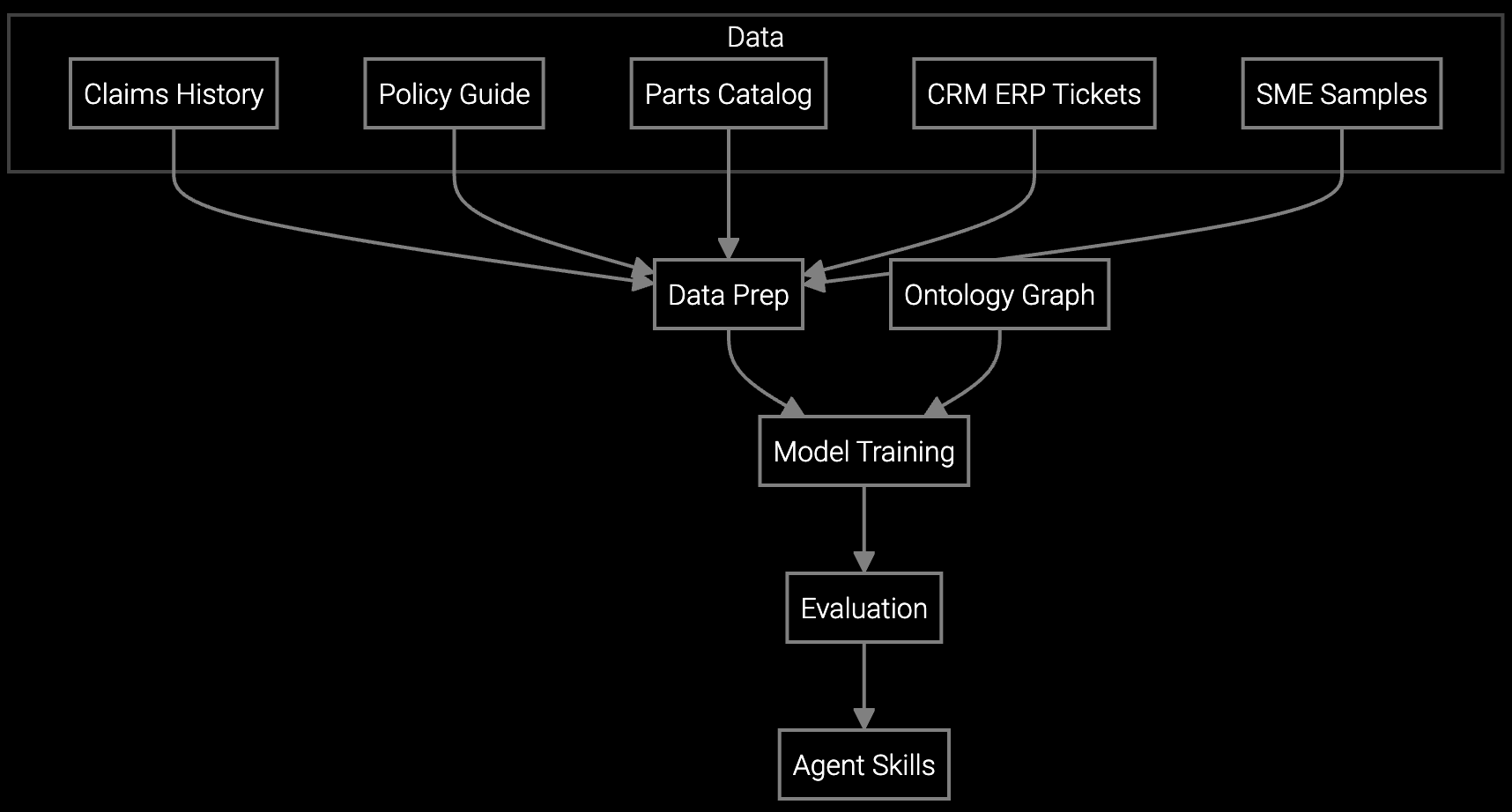

The platform ingests warranty claim descriptions and cross-references them against equipment telemetry logs, maintenance history, and past failure patterns. When a claim arrives describing intermittent motor vibration on a CNC machine, the system checks sensor data from the week before the claim. If accelerometer readings show normal vibration profiles and no deviation from baseline, the claim gets flagged for additional diagnostics before issuing an RMA.

Claims processors see a pre-authorization diagnostic score that separates genuine failures from installation errors, operator misuse, or environmental conditions. The workflow presents verification steps tailored to the claim type—voltage logs for electrical symptoms, temperature profiles for thermal failures, cycle counts for wear patterns. You approve or deny RMAs based on evidence, not just claim descriptions.

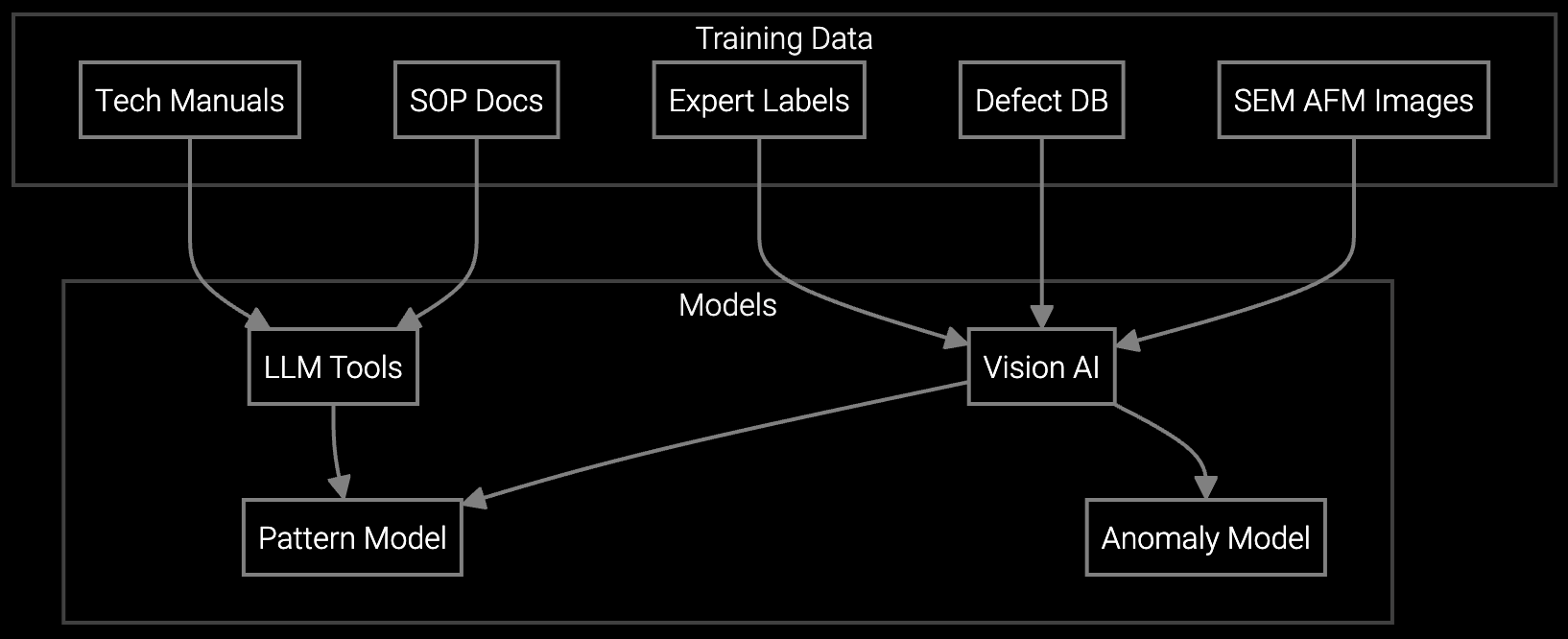

Automate microscopic failure analysis for turbine blades and compressor components, identifying genuine metallurgical defects versus wear-and-tear to validate warranty claims.

Classify claims by failure mode, component type, and root cause to route high-NFF categories for pre-authorization verification and streamline valid claims.

Industrial equipment operates in harsh environments where environmental factors—voltage fluctuations, temperature extremes, contamination—often mimic component failures. Customer service teams authorize RMAs based on reported symptoms, but returned CNC controllers, hydraulic pumps, or PLCs frequently test within specification at the refurbishment center.

Long equipment lifecycles amplify the problem. A compressor manufactured 15 years ago may have obsolete sensors or undocumented firmware revisions, making failure diagnosis dependent on tribal knowledge. When that knowledge walks out the door, NFF rates climb as processors err toward authorizing returns rather than risk denying valid claims.

The system looks up equipment serial numbers in your installed base database and retrieves telemetry from connected data sources. For unconnected legacy equipment, the platform relies on maintenance history and past failure patterns for the model family to provide diagnostic context.

Claims processors retain final authorization authority. The platform presents diagnostic evidence and suggests verification steps, but you decide whether to approve the RMA. Overrides feed back into the model to improve future scoring accuracy.

Yes. The platform identifies patterns indicating misuse—operating hours beyond rated duty cycle, exposure to out-of-spec voltages, or maintenance intervals missed per service logs. It flags these for human review rather than automatically denying claims.

Verification scoring runs in under 10 seconds per claim. For flagged claims requiring additional diagnostics, processors spend 3-5 minutes reviewing evidence—far less than the 14+ days and $850+ cost of processing an invalid return.

Partially. For unconnected equipment, the platform uses maintenance records, past failure data for that product family, and claim symptom analysis. Verification accuracy improves with connectivity, but historical pattern matching still catches many invalid returns.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how Bruviti's pre-authorization diagnostics cut NFF rates in 90 days.

Schedule Demo