Every unnecessary return costs your service operation time, money, and customer trust—and most are preventable with the right diagnostic workflow.

AI-powered pre-authorization diagnostics verify failure symptoms before return approval, reducing NFF rates by 40-60% through automated telemetry analysis and guided diagnostic verification workflows that catch user error and installation issues before products ship back.

No Fault Found returns burn warranty reserves without fixing real problems. Reverse logistics, inspection time, and refurbishment costs add up while the original customer complaint remains unresolved.

Each return requires manual entitlement verification, RMA generation, and disposition tracking. High NFF volumes overwhelm warranty processors, delaying legitimate claims and creating backlog in refurbishment centers.

Customer descriptions like "doesn't work" or "making noise" get approved without diagnostic validation. Units arrive with nothing wrong, but processors lack context to determine if the issue was user error or intermittent failure.

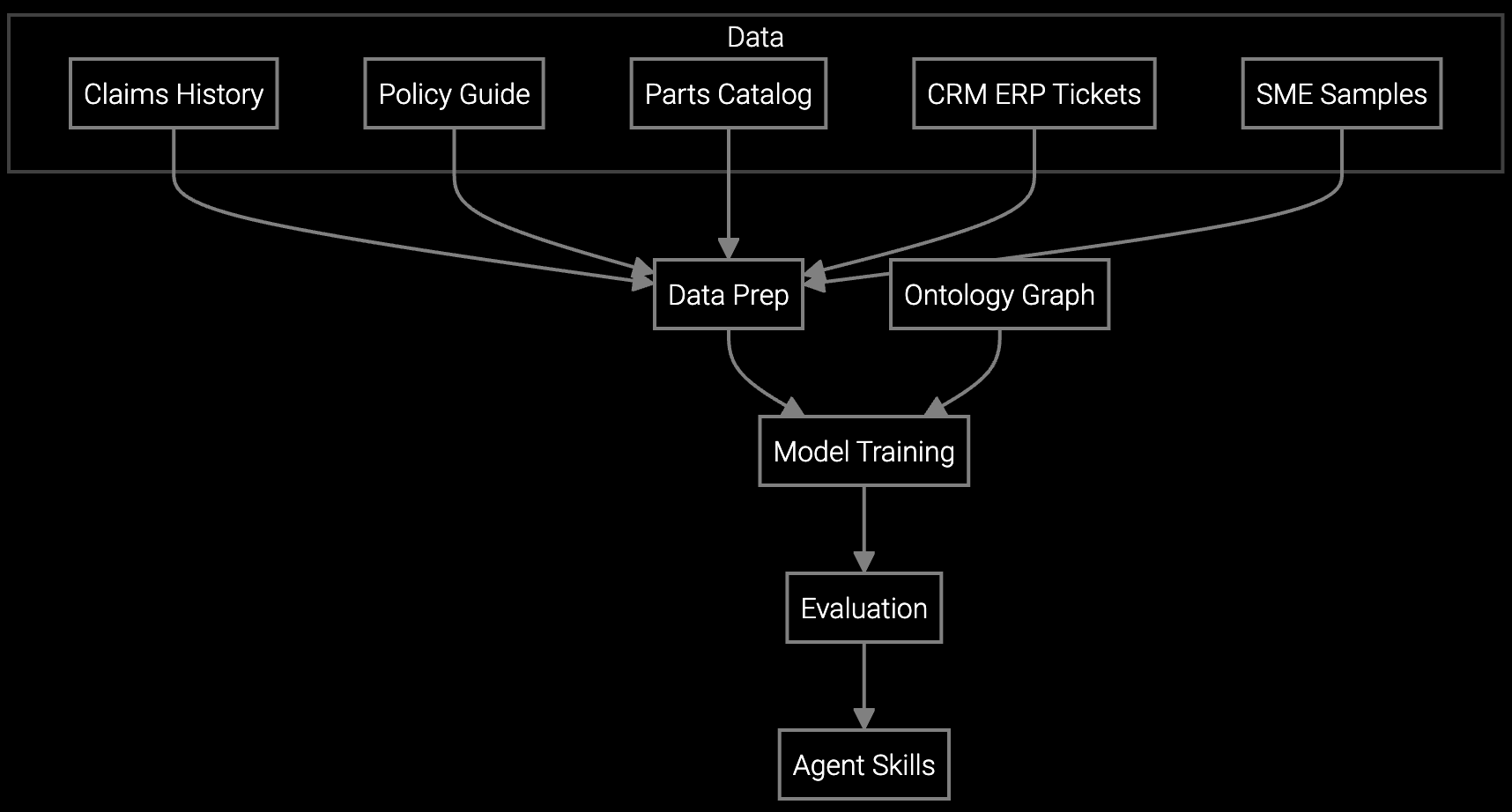

The platform automates pre-authorization workflows that verify failure symptoms before generating RMAs. When a warranty claim arrives, the system analyzes telemetry from connected appliances, cross-references symptom patterns against known failure modes, and flags likely user error or installation issues. You review flagged cases with full diagnostic context instead of approving returns blind.

For non-connected appliances, guided diagnostic verification workflows walk customers through verification steps before return approval. The system captures responses, detects inconsistencies, and presents you with a resolution case showing whether the symptom is reproducible or likely environmental. Claims that pass validation proceed to RMA generation automatically—no manual lookup or data entry required.

Automatically classifies appliance warranty claims by failure mode, validates entitlement against registration data, and routes to refurbishment or replacement based on repair economics.

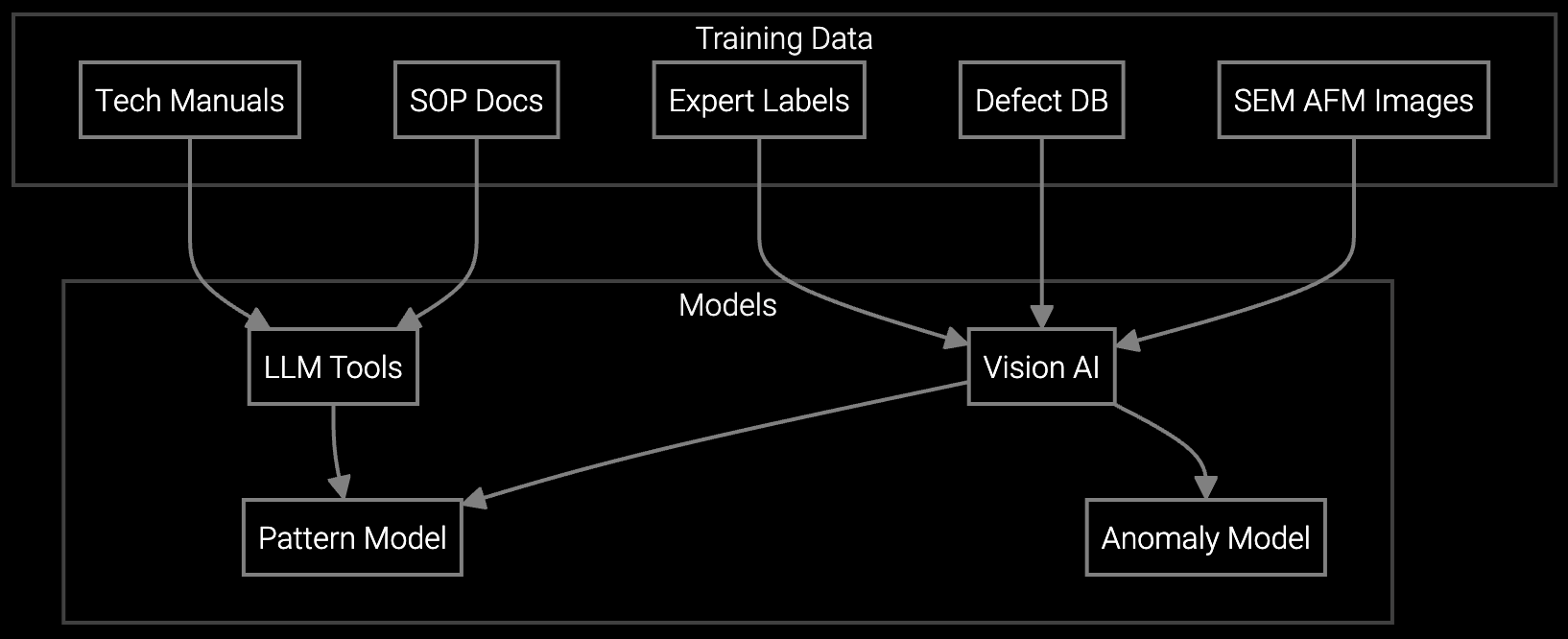

Analyzes photos submitted with appliance returns to identify visible defects, classify failure modes, and validate whether damage is warranty-covered or user-caused.

Appliance manufacturers face unique NFF challenges driven by high claim volumes, seasonal demand spikes, and customer expectations for immediate resolution. Refrigerators, HVAC systems, and washers generate warranty claims at scale—often with vague symptom descriptions like "not cooling" or "won't start" that could indicate real failures, user error, or installation problems.

Connected appliances provide IoT telemetry showing actual operating conditions, but most warranty processors lack tools to analyze that data during claim triage. Legacy systems require manual symptom entry and entitlement lookup, slowing processing and allowing questionable returns through unchallenged. The result: refurbishment centers flooded with units showing no defects, warranty reserves drained by reverse logistics costs, and legitimate claims delayed by backlog.

The platform generates guided diagnostic verification workflows based on the reported symptom and model. Customers answer diagnostic questions or submit photos, and the system analyzes responses for consistency with known failure modes. If responses indicate user error or installation issues, the claim is flagged for processor review with full diagnostic context before return authorization.

You retain final approval authority. The system flags likely NFF cases and presents diagnostic evidence, but you decide whether to approve the return, request additional troubleshooting, or escalate to a service call. The goal is to give you context, not block legitimate claims.

Yes. Bruviti integrates with warranty platforms via API to pull entitlement data and push RMA decisions. The diagnostic layer sits between claim submission and RMA generation, automating verification without replacing your existing workflow.

Most appliance manufacturers see measurable NFF reduction within 30-60 days of deployment. The system learns failure patterns from your historical claims data, so accuracy improves as it processes more claims. Early wins typically come from filtering obvious user error cases like incorrect installation or power issues.

Yes. The platform includes image analysis to identify visible defects, corrosion, or physical damage in submitted photos. This helps distinguish warranty-covered failures from user-caused damage and validates symptom descriptions before return authorization.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how Bruviti's automated diagnostics reduce unnecessary returns and speed up legitimate warranty claims.

Schedule Demo