Fab equipment warranty claims drain millions annually while manual processing delays resolution and inflates reserves.

Deploy AI warranty systems by integrating claims data feeds with your ERP, training fraud detection models on historical NFF patterns, and automating entitlement verification. Semiconductor OEMs typically pilot with high-volume tool categories (lithography, etch) to demonstrate 15-25% NFF reduction within 90 days before enterprise rollout.

Warranty claims data sits fragmented across ERP, CRM, and service management systems. Manual reconciliation delays model training and prevents real-time fraud detection from launching.

No Fault Found returns cost semiconductor OEMs millions, but pattern data lives in unstructured service notes. Without digitized training sets, AI models cannot learn to predict invalid claims.

Warranty teams fear AI will flag legitimate claims as fraud or slow processing. Without executive sponsorship and phased rollout plans, pilot deployments stall in committee.

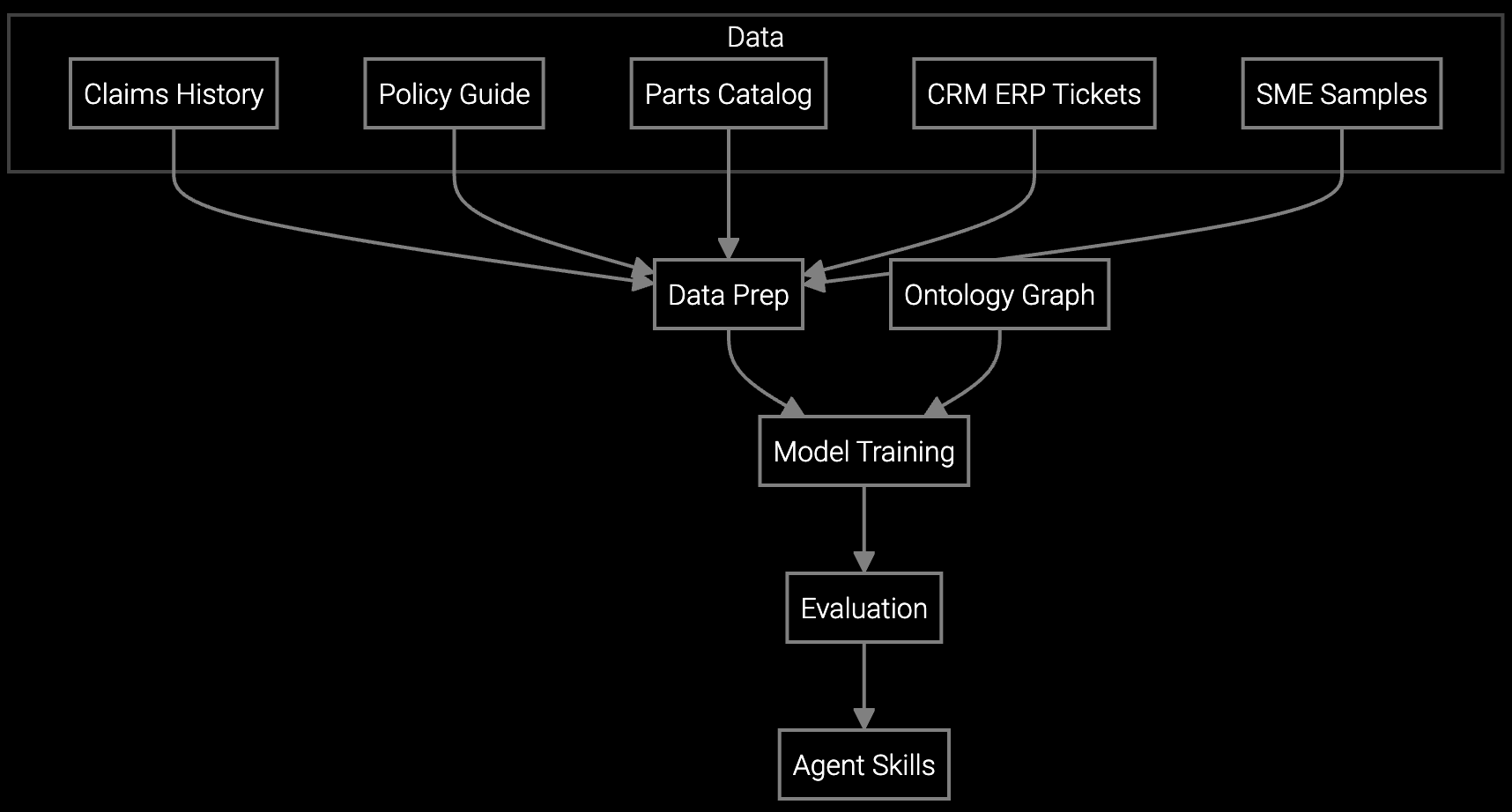

Successful AI warranty deployments start with data pipeline architecture, not model tuning. Bruviti connects directly to your existing warranty systems via API or batch file ingestion, consolidating claims history, RMA records, and refurbishment outcomes into a unified training dataset. The platform identifies NFF patterns by correlating returned unit serial numbers with service records, environmental telemetry, and operator-reported symptoms—creating the ground truth needed to train fraud detection algorithms.

Deploy in phases to build organizational confidence. Begin with a read-only shadow mode where AI flags suspicious claims for manual review without blocking processing. As teams validate accuracy, transition to automated entitlement verification for low-risk claims, then expand to full adjudication for high-volume tool categories. This staged approach delivers measurable reserve reductions within one quarter while preserving manual override pathways for complex edge cases.

Automatically classify and code warranty claims from lithography, etch, and deposition tools, reducing manual processing time and improving accuracy for high-value equipment returns.

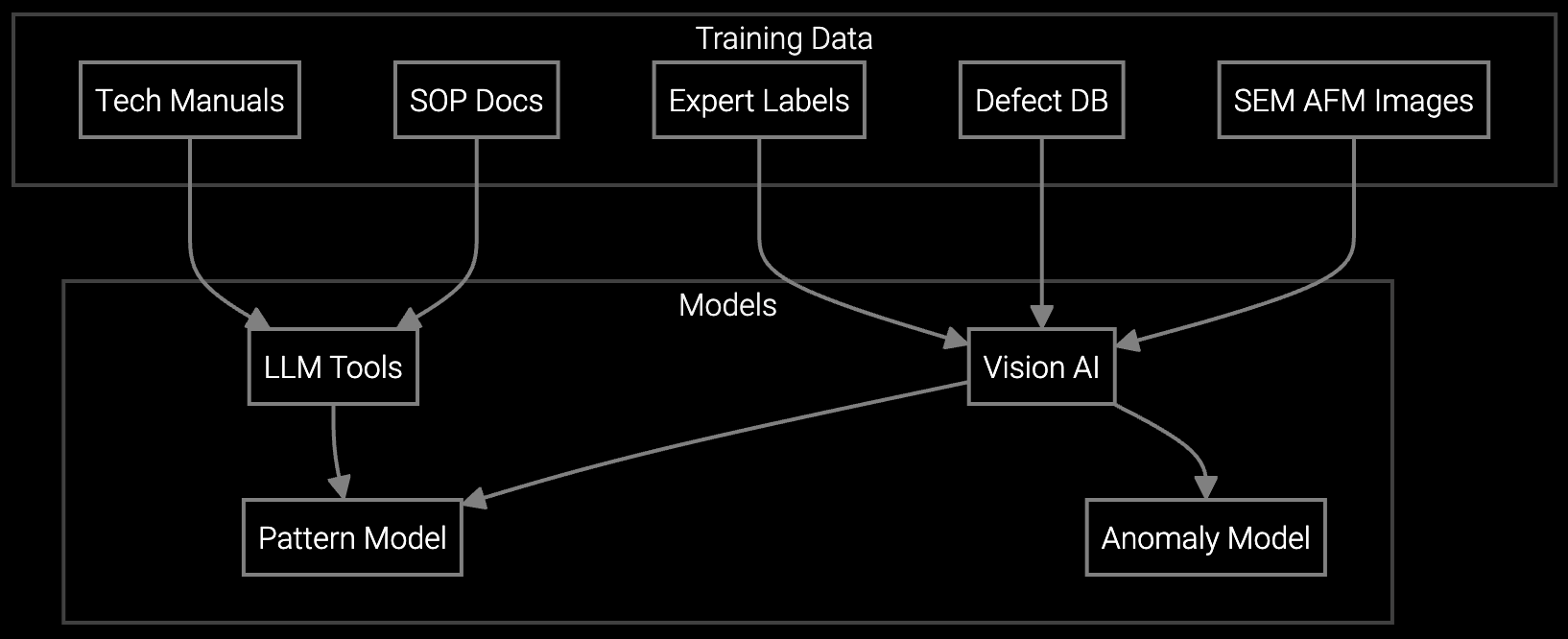

AI analyzes scanning electron microscope and atomic force microscope images from returned wafers to identify true defects, validate warranty claims, and reduce No Fault Found returns.

Semiconductor tool warranty claims involve extreme capital costs—a single EUV lithography system costs $150M+ with proportional warranty exposure. Unlike consumer electronics, claim validation requires analyzing process telemetry (chamber pressure, RF power, gas flow rates) alongside failure symptoms to distinguish true defects from recipe drift or operator error. The platform ingests telemetry streams from your installed base via OPC-UA or proprietary fab automation protocols, correlating tool health metrics with warranty events.

Refurbishment logistics add complexity. Returned components like RF generators or vacuum pumps undergo metrology testing that generates structured reports—the AI learns to predict NFF outcomes before units ship, saving reverse logistics costs. For wafer defect claims, the system analyzes SEM images to validate contamination or process-induced failures, providing defensible documentation for warranty adjudication with foundry customers.

You need historical claims data (symptoms, failure codes, resolution times), RMA records with refurbishment outcomes, returned unit serial numbers, and service history for those serial numbers. For semiconductor tools, add process telemetry from fab automation systems to correlate tool health with failure modes. The AI identifies NFF patterns by finding claims where returned units passed all refurbishment tests.

Data integration and model training typically require 60-90 days for a single tool family pilot. Shadow-mode deployment (AI flags claims for manual review without blocking workflows) launches at 90 days. After validating accuracy for one quarter, full automation for high-volume claims scales enterprise-wide within 6-9 months. Timeline depends on ERP complexity and clean historical data availability.

Deploy in shadow mode first—the AI flags suspicious claims but all processing continues manually. Review flagged claims with your warranty team to validate accuracy before enabling automated blocking. Retain manual override pathways for complex cases or high-value customer accounts. Precision rates above 95% are standard before transitioning from advisory to automated adjudication.

Pilot deployments on high-volume tool categories demonstrate 15-25% NFF reduction within 90 days by preventing invalid claims from reaching refurbishment. Enterprise rollout across all tool families typically reduces total warranty reserves 10-18% annually as the models learn new fraud patterns. Savings compound over time as historical claims data grows and model accuracy improves.

Bruviti connects to fab automation networks via OPC-UA, SECS/GEM, or proprietary APIs to ingest tool telemetry. The platform correlates process parameters (chamber temperature, RF power, gas flows) with warranty claims to identify recipe drift or operator error that mimics equipment defects. No changes to existing fab control systems required—data flows one-way from automation to the warranty AI platform.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how semiconductor OEMs reduce warranty reserves 15-25% with automated fraud detection and NFF prediction.

Schedule Implementation Briefing