Rising NFF rates and warranty reserve volatility demand strategic deployment that proves ROI before scaling.

Industrial OEMs implement AI warranty analytics through phased integration starting with high-volume claim types, connecting existing PLM and ERP data feeds, and measuring NFF reduction over 90-180 days to validate ROI.

Warranty data sits in isolated systems across ERP, PLM, and legacy claim platforms. Without unified data pipelines, AI models train on incomplete information and produce unreliable predictions that undermine leadership confidence.

Finance leadership demands clear payback periods before authorizing AI investments. Without defined milestones linking NFF reduction to margin protection, warranty analytics projects languish in procurement.

Claims processors and warranty analysts resist new workflows that alter established manual processes. Without executive sponsorship and phased rollout, AI tools fail to achieve operational integration.

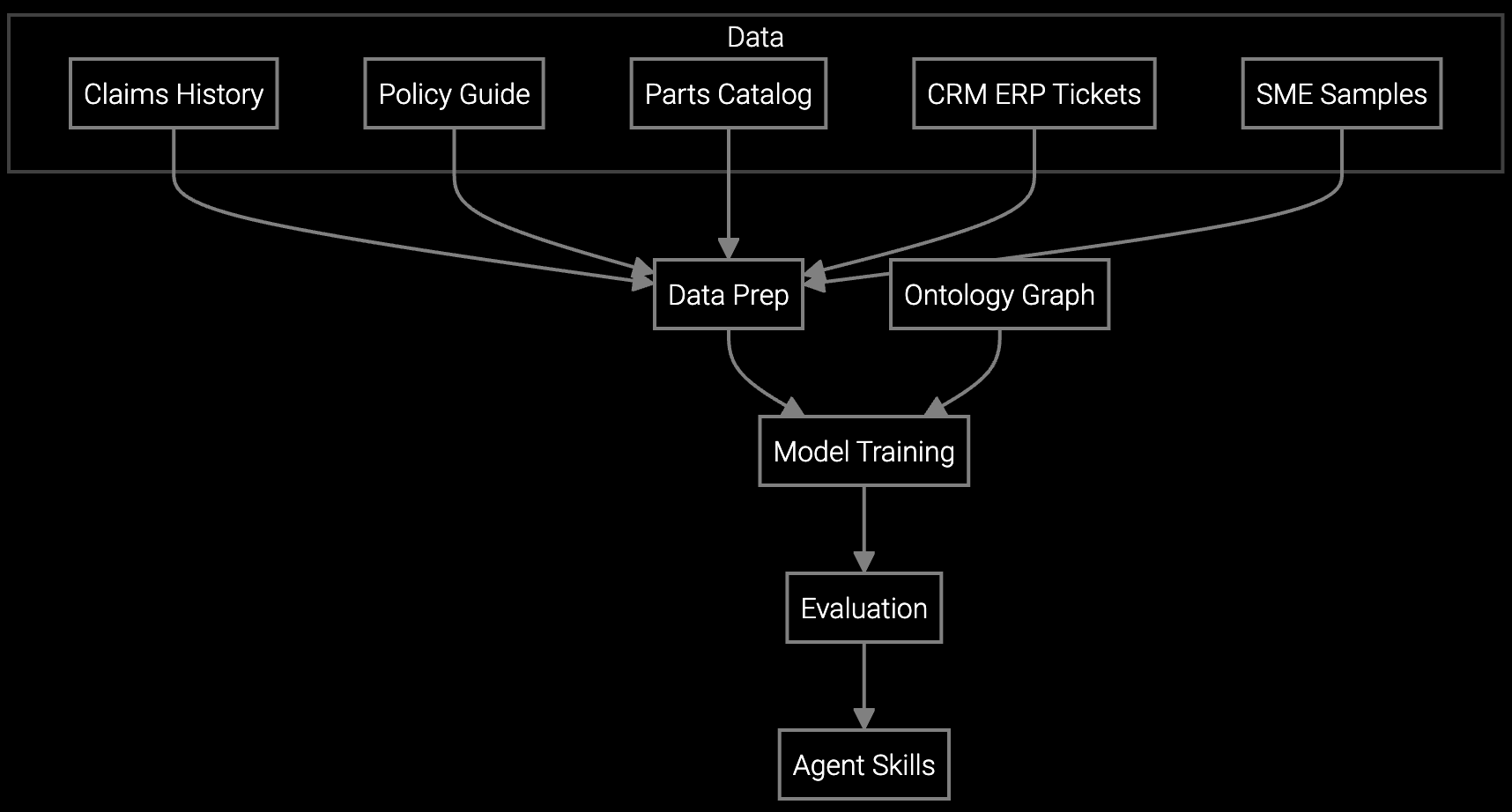

Bruviti's phased implementation approach addresses the executive's mandate for measurable ROI while managing organizational risk. The platform connects to existing PLM, ERP, and warranty systems through standard APIs, eliminating the need for disruptive data migration or system replacement. Start with a focused pilot targeting the single highest-volume claim category—typically motors, pumps, or CNC spindles—to establish baseline NFF rate and claim processing time.

The platform's self-learning fraud detection and entitlement verification models refine predictions as claim volume grows, with executive dashboards tracking warranty reserve impact weekly. This approach allows CFO-level visibility into margin protection while operational teams validate AI recommendations against manual processes during the 90-day pilot phase before full deployment.

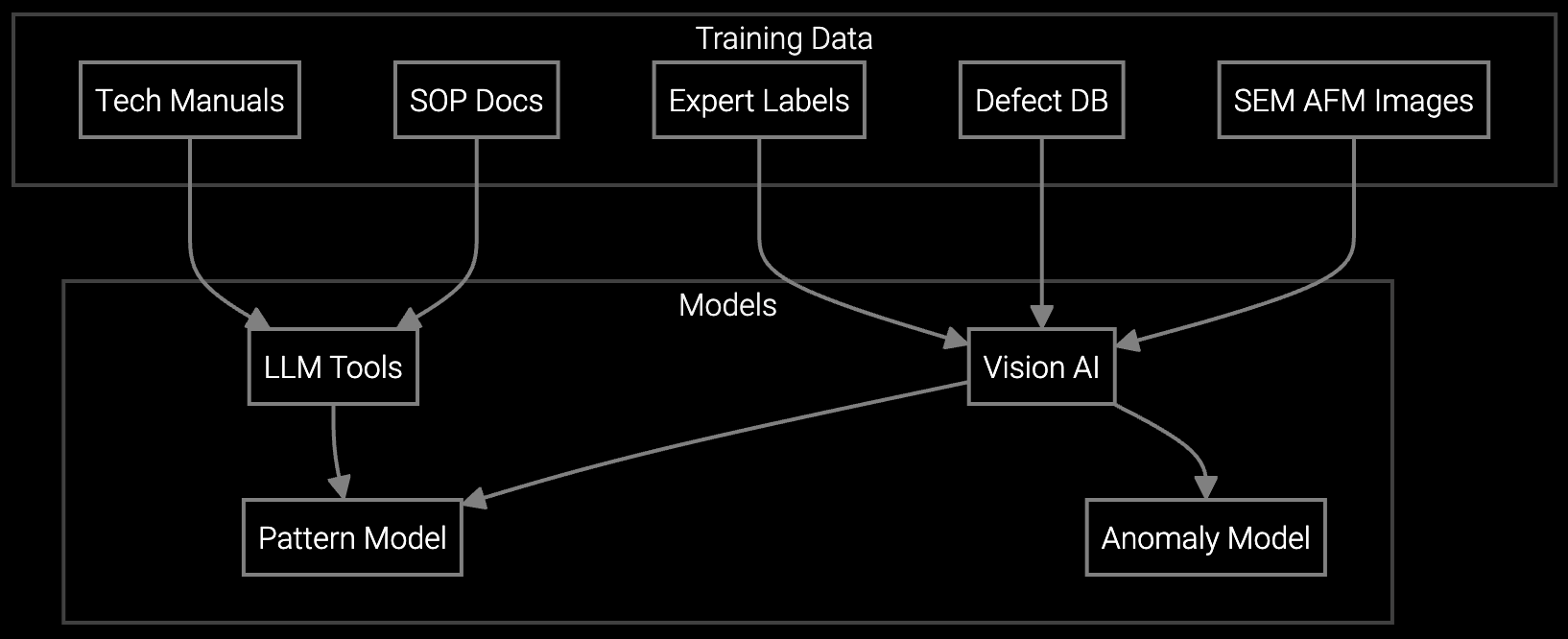

AI analyzes microscopic images of returned industrial components to identify mechanical failures, validate warranty claims, and classify defect patterns across turbine blades, bearing surfaces, and precision-machined parts.

Automatically classifies warranty claims by failure mode, component type, and root cause for industrial machinery, reducing manual coding effort while improving warranty analytics accuracy for reserve planning.

Industrial equipment manufacturers face unique warranty analytics challenges due to multi-decade product lifecycles and geographically dispersed installed bases. Heavy machinery claims involve complex failure modes spanning hydraulics, pneumatics, controls, and mechanical systems. Equipment deployed in mining, construction, and manufacturing operates in harsh environments that complicate root cause analysis.

AI warranty analytics for industrial OEMs must process diverse data sources including PLC logs, SCADA telemetry, service bulletins, and field service reports accumulated over 10-30 year equipment lifespans. The platform trains on historical claim patterns to identify fraudulent returns, predict failure-prone serial number ranges, and validate entitlement for equipment with complex service contract structures across distributors and third-party service providers.

AI warranty analytics requires claims history, equipment configuration data from PLM systems, service history, failure mode codes, refurbishment outcomes, and parts hierarchy data. Industrial OEMs should also integrate PLC telemetry, SCADA logs, and field service reports where available to improve root cause prediction accuracy.

Bruviti's phased approach delivers initial results in 90 days with a focused pilot on one product line or claim category. Data integration typically requires 2-4 weeks, model training 3-4 weeks, and operational validation 6-8 weeks. Full enterprise deployment across all product lines scales over 6-12 months depending on portfolio complexity.

Industrial equipment OEMs typically achieve 15-25% NFF reduction, 30-40% faster claim processing, and 10-20% improvement in warranty reserve forecast accuracy. Combined, these improvements deliver 1.5-3% warranty cost reduction as a percentage of revenue. ROI timelines range from 12-18 months depending on claim volume and NFF baseline rates.

No, Bruviti integrates with existing SAP, Oracle, or custom ERP warranty systems through APIs. The platform augments manual processes with AI-powered fraud detection, entitlement verification, and predictive analytics while preserving existing workflows and system investments. Claims still flow through established approval chains.

Successful adoption requires executive sponsorship, phased rollout starting with a pilot team, and transparent AI recommendations alongside manual processes during validation. Bruviti provides training for claims processors, executive dashboards for leadership visibility, and configurable approval thresholds that preserve human oversight during the transition period.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

Bruviti's executive team will design a phased implementation plan tailored to your product portfolio and ROI requirements.

Schedule Strategy Session