Invalid RMA claims erode warranty reserves by 12-18% annually while network downtime penalties create margin pressure OEMs can't sustain.

Network OEMs implement AI warranty systems by integrating claims data with device telemetry feeds, training fraud detection models on historical RMA patterns, and automating entitlement verification through API connections to ERP systems—reducing NFF rates while protecting warranty reserves.

Routers and switches returned under warranty often show no defect upon inspection. Without telemetry-driven validation, OEMs process unnecessary RMAs that consume refurbishment capacity and inflate warranty costs.

Manual warranty lookups across multiple systems delay claim approvals. When network outages trigger SLA penalties, slow entitlement verification costs OEMs both customer satisfaction and margin.

Unpredictable warranty costs force conservative reserve accruals. Without AI-driven fraud detection and failure prediction, CFOs over-provision reserves that tie up capital and pressure operating margins.

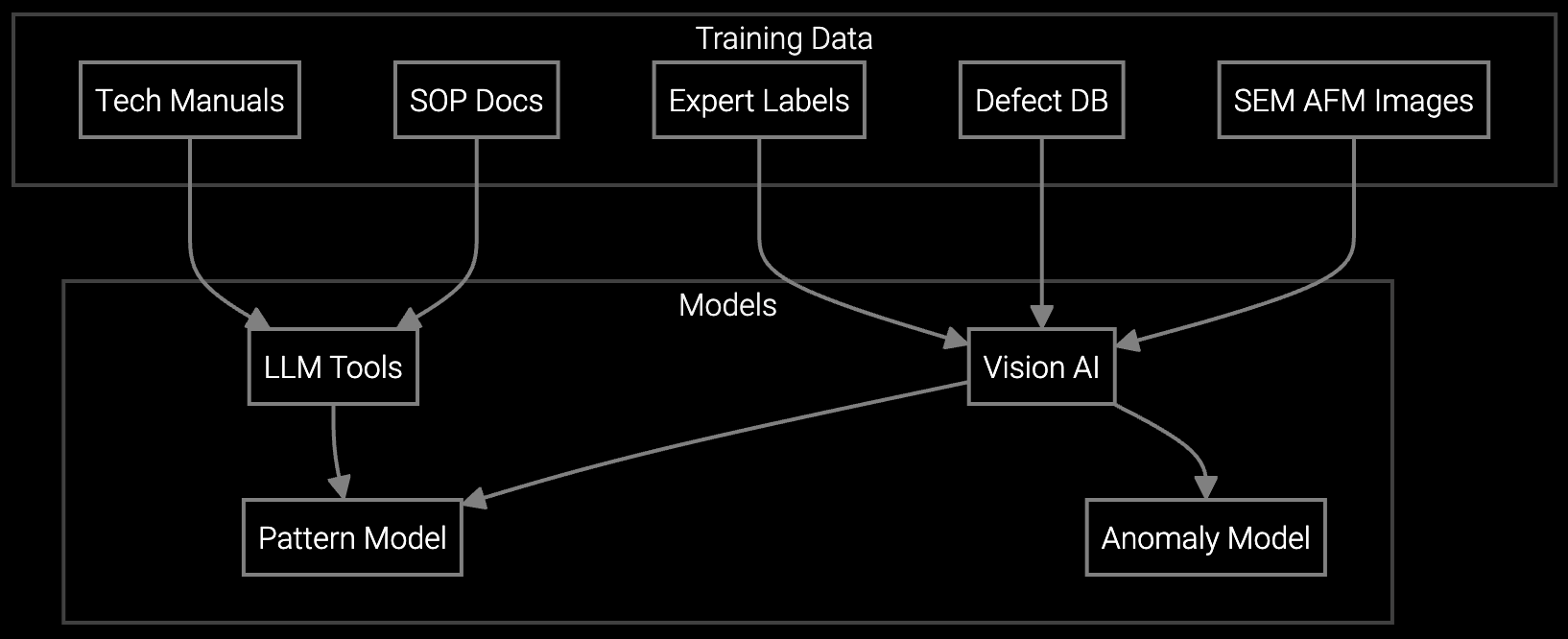

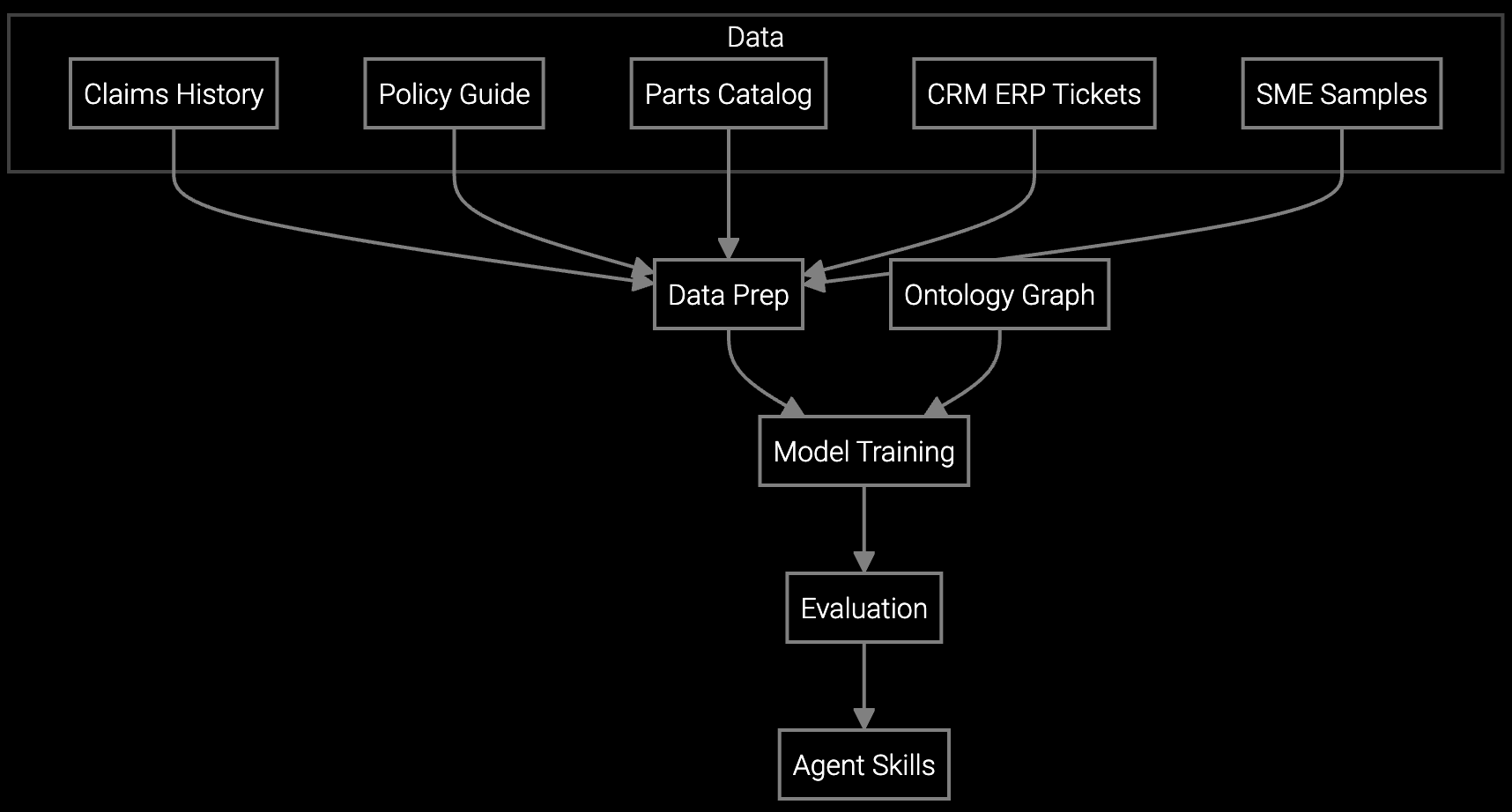

Bruviti's platform deploys in three phases: data integration, model training, and workflow automation. First, connect warranty claims history to device telemetry streams from SNMP traps, syslog, and network management systems. The AI ingests failure patterns, RMA outcomes, and refurbishment dispositions to establish baseline accuracy before processing live claims.

Second, deploy fraud detection models trained on historical RMA patterns. The system flags anomalies—duplicate serial numbers, claims outside warranty periods, or devices showing no error logs prior to return. Integration with ERP systems enables instant entitlement verification, eliminating manual lookups that delay claim approvals during network outages.

Network equipment manufacturers use AI to analyze microscopic board-level defects in returned routers and switches, validating warranty claims and identifying manufacturing quality issues.

Automatically classify RMA claims for network infrastructure, routing firewall claims to security team review while switch failures trigger supply chain alerts for batch defects.

Network gear generates rich diagnostic data through SNMP traps, syslog streams, and embedded firmware health checks. Connect these telemetry feeds to the AI platform before processing warranty claims. Router error logs showing thermal events, power supply fluctuations, or firmware crashes provide ground truth for validating customer-reported failures.

Integrate with existing warranty management systems through REST APIs. The platform ingests serial numbers, entitlement dates, and claim histories to establish baseline fraud patterns. For carrier-grade equipment with five-nines uptime requirements, prioritize integration of NOC ticketing systems to correlate customer-reported outages with device telemetry.

The platform requires three data types: warranty claims history with RMA outcomes, device telemetry feeds from SNMP traps and syslog, and entitlement records from ERP systems. Most network OEMs already collect this data but store it in siloed systems. Integration typically takes 4-6 weeks for pilot deployment.

The system correlates customer-reported failures with actual device telemetry prior to the claim. If a router shows no error logs, thermal events, or firmware crashes before the RMA request, the AI flags it for additional validation. This prevents unnecessary returns while maintaining customer trust through transparent diagnostic evidence.

Network OEMs typically reduce warranty reserves by 15-22% within 12 months of deployment. AI-predicted failure rates based on telemetry patterns replace conservative actuarial estimates, enabling more accurate accruals. This frees working capital while maintaining adequate coverage for legitimate claims.

Pilot deployment on a single product line takes 8-12 weeks including data integration, model training, and workflow automation. Full portfolio rollout across routers, switches, and firewalls typically requires 6-9 months as the platform learns unique failure signatures for each device family.

Bruviti connects to warranty databases through REST APIs to retrieve entitlement records and claim histories. The platform also integrates with ERP systems for real-time serial number validation and refurbishment tracking. Most integrations use standard webhooks to trigger AI analysis when new claims are submitted.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

Connect with Bruviti's implementation team to map your warranty data sources and design your deployment roadmap.

Schedule Implementation Review