Manual asset tracking delays maintenance scheduling and leaves fab managers searching spreadsheets when tools fail.

Automated installed base tracking consolidates asset data, configuration status, and lifecycle events into a single real-time view. For semiconductor OEMs, this eliminates manual serial number lookups and spreadsheet reconciliation, enabling proactive maintenance scheduling and contract renewal visibility across thousands of deployed tools.

Service teams lack visibility into chamber configurations, software versions, and recipe parameters across deployed lithography and etch tools. When equipment fails, engineers spend hours reconstructing the configuration history before diagnosing the issue.

Actual tool configurations diverge from documented settings as fabs adjust recipes and update software. This drift creates compliance risks and makes it impossible to predict which tools need preventive maintenance or chamber kit replacements.

Without automated entitlement tracking, service teams miss contract expiration dates and fail to identify tools eligible for upgrades. This leaves revenue on the table and reduces customer lifetime value.

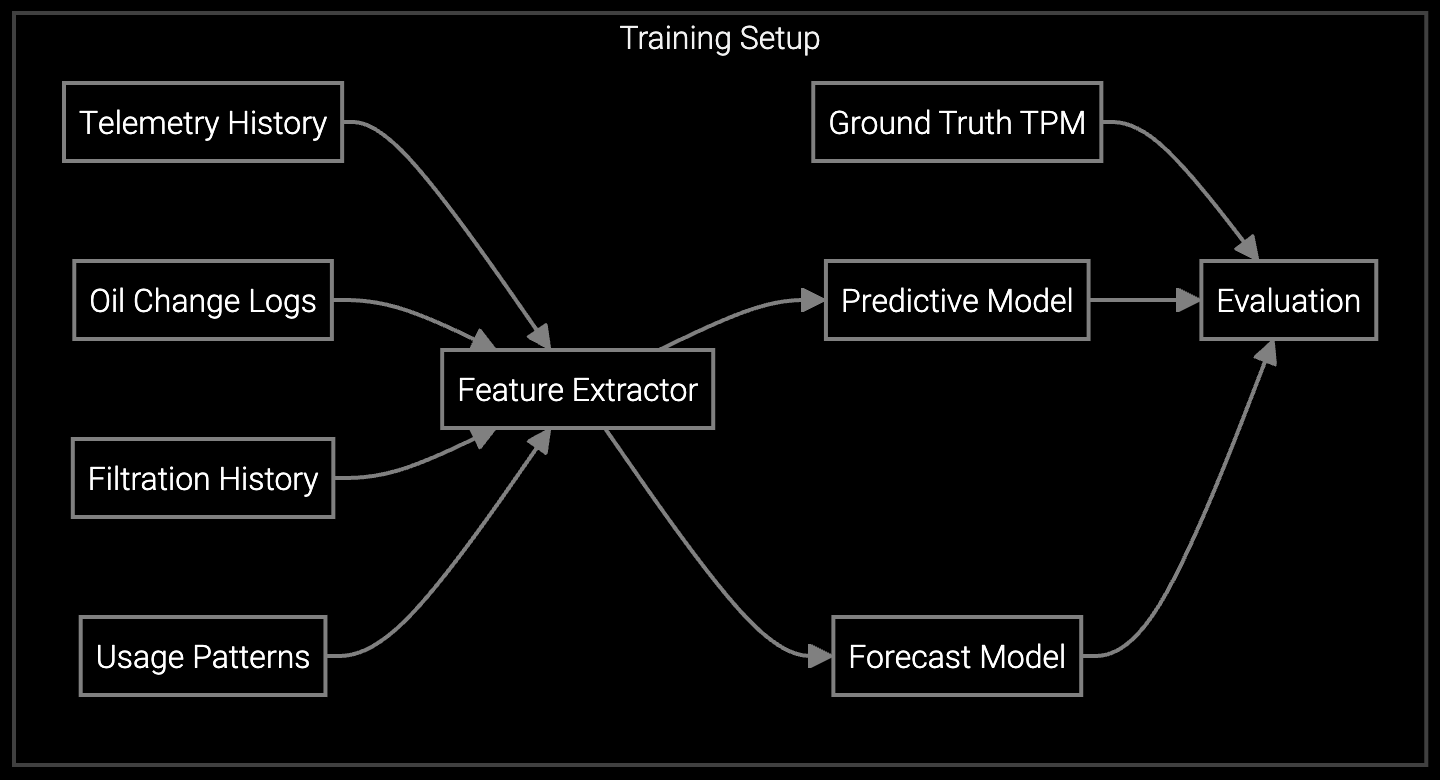

Bruviti's platform automatically ingests telemetry data from deployed semiconductor tools, tracking serial numbers, configuration changes, software versions, and maintenance history in real time. The system continuously reconciles actual tool status against documented records, flagging configuration drift and alerting service teams when entitlements approach expiration.

For service coordinators managing hundreds of tools across multiple fabs, this means opening one screen to see complete equipment history, contract status, and predictive maintenance schedules. The platform surfaces actionable alerts for upcoming PM cycles, EOL components, and upgrade candidates, eliminating the need to cross-reference CRM, ERP, and telemetry systems.

Virtual models of deposition tools track real-time chamber conditions, enabling predictive alerts for consumable replacement before process drift impacts wafer yield.

Estimates when chamber kits and RF generators will reach end of life based on usage patterns and telemetry trends, enabling planned maintenance during scheduled downtime windows.

Schedules PM cycles based on actual tool condition and process chamber hours rather than fixed intervals, reducing unnecessary maintenance while preventing unplanned downtime.

Semiconductor equipment OEMs manage installed bases spanning thousands of lithography systems, etch tools, and deposition chambers worth $10M+ each. These tools generate continuous telemetry streams including recipe parameters, chamber sensor readings, and consumable usage data. Tracking configuration changes across this installed base is critical for predicting maintenance needs and ensuring process consistency.

Automated asset tracking integrates directly with fab telemetry systems to capture real-time configuration status. The platform monitors software version updates, recipe modifications, and chamber component replacements, creating an auditable history of every tool. This visibility enables service teams to identify which tools require urgent attention and which are candidates for capacity upgrades or EOL component replacements.

The platform supports manual data entry and periodic batch uploads for older tools. Service teams can enter configuration snapshots during PM visits, and the system flags tools with stale data for validation. Over time, integrating even partial telemetry from legacy equipment improves coverage.

Many fabs limit external access to telemetry for security reasons. In these cases, the platform can ingest service visit reports, parts orders, and warranty claim data to maintain asset history. While less granular than real-time telemetry, this approach still provides visibility into configuration changes and maintenance cycles.

Configuration drift detection begins within days of integration. The platform compares current tool configurations against baseline records and flags discrepancies immediately. Teams typically see the first drift alerts within the first week as the system processes telemetry data.

Yes. The system monitors software versions for every connected tool and alerts when tools fall out of compliance with recommended versions. This is particularly important for fabs running critical process recipes where software version consistency directly impacts yield.

The platform automatically flags tools with contracts approaching expiration and surfaces upgrade candidates based on equipment age and utilization. Service coordinators receive prioritized renewal lists instead of manually searching contract databases, reducing the time required to identify and pursue renewal opportunities.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

Stop searching spreadsheets. Get real-time asset visibility with Bruviti.

Schedule Demo