Manual asset tracking drains resources while equipment records drift out of sync, eroding predictive maintenance ROI.

Automate asset tracking and configuration management by connecting equipment telemetry to digital twin models, eliminating manual audits and reducing configuration drift from 15% to under 2% across fab environments.

Missing serial numbers and configuration details prevent accurate lifecycle tracking. Equipment upgrades and EOL planning require manual audits that consume engineering time and delay critical decisions.

Actual tool configurations diverge from system records as firmware updates and recipe changes occur. Predictive models trained on stale configuration data generate false positives and miss real failures.

Service contracts expire unnoticed when equipment records fail to trigger renewal workflows. Revenue leaks while customers operate tools without coverage, exposing both parties to unplanned downtime costs.

Bruviti orchestrates the entire installed base management lifecycle by connecting equipment telemetry to digital twin models. The platform automatically updates asset records when tools report firmware changes, recipe parameter adjustments, or chamber component replacements. Configuration drift detection runs continuously, flagging discrepancies before they corrupt predictive maintenance models.

Contract renewal workflows trigger automatically based on equipment deployment dates and service agreement terms stored in the digital twin. The system identifies upgrade candidates by comparing installed configurations against current product offerings, prioritizing tools that would benefit most from performance improvements or EOL component replacement.

Virtual models of lithography and etch tools track real-time performance against baseline parameters, enabling proactive maintenance before process drift impacts wafer yield.

Estimates chamber component lifespan based on usage patterns and process recipe intensity, scheduling preventive maintenance during planned downtime windows instead of emergency shutdowns.

Schedules PM cycles based on actual tool condition rather than fixed intervals, reducing unnecessary maintenance events while preventing unplanned downtime that costs $1M+ per hour.

Semiconductor fabs operate 300+ process tools across lithography, etch, deposition, and metrology. Each tool's configuration directly impacts wafer throughput and yield. When asset records fail to reflect chamber kits, firmware versions, or recipe parameters, predictive models trained on outdated data generate false alerts that waste engineering time.

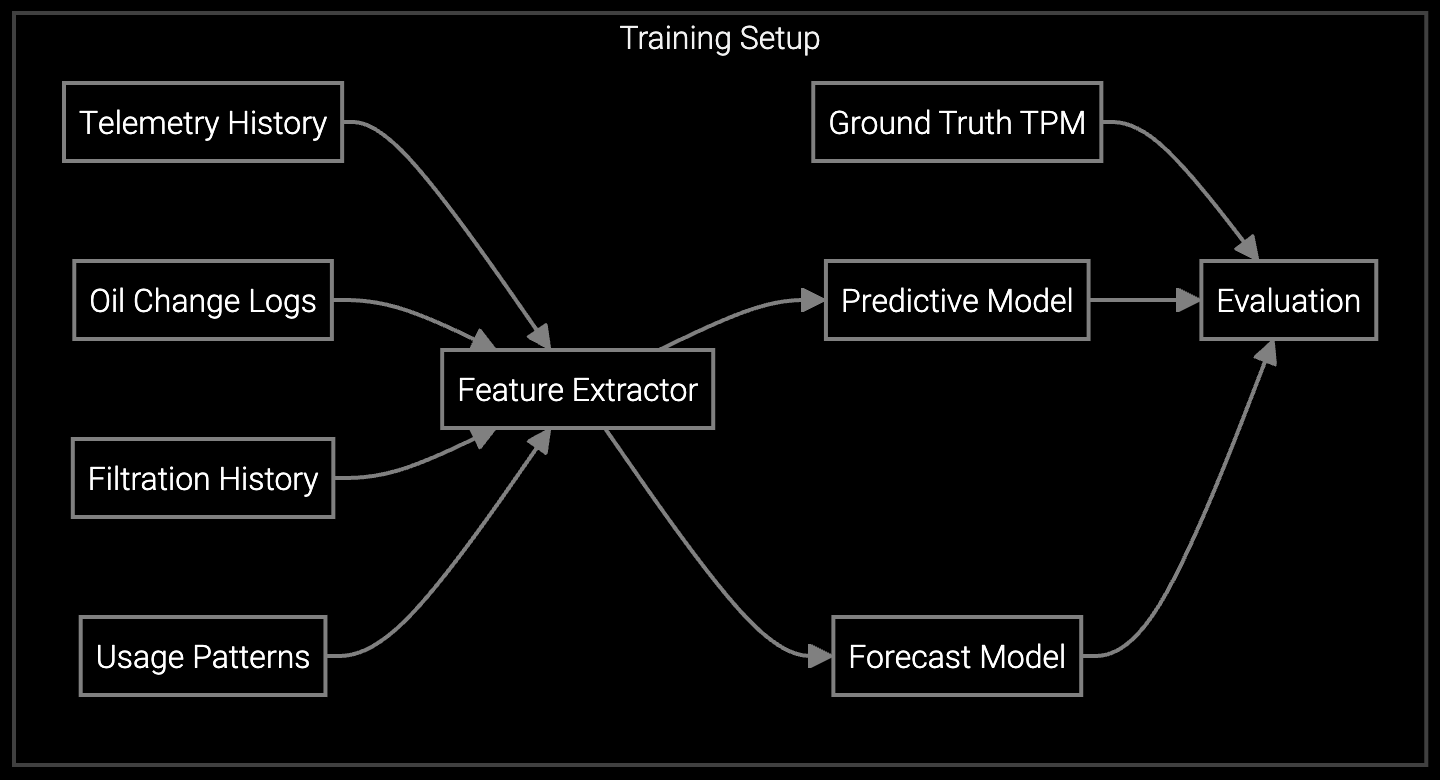

Automated configuration tracking eliminates the manual audit cycle that traditionally consumes 10+ hours per tool per quarter. The platform ingests equipment telemetry continuously, updating digital twin models whenever tools report changes. This real-time accuracy enables predictive maintenance systems to distinguish between normal process variation and genuine drift requiring intervention.

The platform continuously ingests equipment telemetry and automatically updates asset records when tools report firmware changes, recipe adjustments, or component replacements. This eliminates quarterly manual audits that traditionally require 10+ engineering hours per tool, freeing resources for higher-value work while maintaining 98%+ data accuracy.

Drift occurs when firmware updates, recipe parameter changes, and chamber component replacements happen in the field but fail to update central asset systems. Process engineers tune recipes locally to optimize yield, maintenance teams swap chamber kits during PM cycles, and these changes never propagate to the configuration database predictive models rely on.

Automated workflows monitor service agreement expiration dates stored in digital twin models and trigger renewal processes 90 days before contracts end. This eliminates the manual tracking burden that allows agreements to lapse, recovering an average $2.3M in annual contract revenue per fab while ensuring customer equipment maintains service coverage.

Firmware version tracking and recipe parameter logs deliver immediate value because they change frequently and directly impact predictive maintenance model accuracy. Chamber component usage counters enable remaining useful life predictions for consumables. Start with these three telemetry types before expanding to environmental sensors and process yield correlation.

Pilot deployments targeting 20-30 critical lithography or etch tools typically reach production in 60-90 days. The platform connects to existing equipment telemetry streams via standard APIs, eliminating custom integration work. Full fab rollouts covering 300+ tools scale over 6-12 months as teams validate configuration accuracy and workflow integration.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how Bruviti eliminates manual asset tracking and recovers contract revenue.

Schedule Demo