Manual tracking of decades-old machinery across global deployments drains margins and obscures upsell opportunities.

Automated installed base workflows orchestrate asset tracking, configuration management, and contract attachment end-to-end—eliminating manual data entry, reducing configuration drift, and identifying upsell opportunities without dedicated headcount.

Legacy equipment deployed over decades lacks serial numbers and configuration details in modern systems. Manual reconciliation consumes administrative time with no ROI.

Field modifications and undocumented upgrades create discrepancies between system records and actual equipment state. Predictive maintenance models fail without accurate configuration data.

Without automated visibility into contract expiration and equipment health, upsell opportunities slip through. Sales teams lack the intelligence to approach customers proactively.

Bruviti's platform executes the entire installed base management workflow autonomously—from asset registration to contract renewal identification. The system ingests PLC, SCADA, and IoT sensor data to maintain real-time equipment records, automatically reconciling configuration changes and flagging discrepancies. Serial number gaps are filled through pattern recognition across telemetry streams and historical service records, eliminating manual data entry.

The AI continuously monitors equipment health, usage patterns, and contract status to surface upsell opportunities before they become failures. Workflow automation extends to EOL/EOS planning, upgrade path identification, and proactive customer outreach—turning installed base management from a cost center into a margin protection engine. Operators see a complete equipment history at a glance; executives gain predictable renewal pipelines without additional headcount.

Virtual models of heavy machinery track real-time performance across global installations, enabling proactive maintenance before failures disrupt production lines.

Analyzes run hours, vibration patterns, and temperature data to estimate when CNC machines and turbines will require replacement, scheduling upgrades during planned downtime.

Automates maintenance windows based on actual equipment condition rather than fixed intervals, reducing unplanned downtime and extending asset lifecycles.

Industrial OEMs support heavy machinery, CNC machines, pumps, compressors, and turbines deployed over decades—often with incomplete documentation and retiring workforce knowledge gaps. Automated installed base workflows reconcile legacy equipment records by analyzing telemetry patterns, cross-referencing service histories, and filling serial number gaps without manual intervention.

The platform tracks run hours, condition-based maintenance triggers, and parts obsolescence timelines across geographically distributed assets. For OEMs serving global manufacturing plants and remote industrial sites, this automation eliminates the administrative burden of maintaining accurate asset registries while enabling predictive maintenance programs that extend equipment lifecycles and protect service margins.

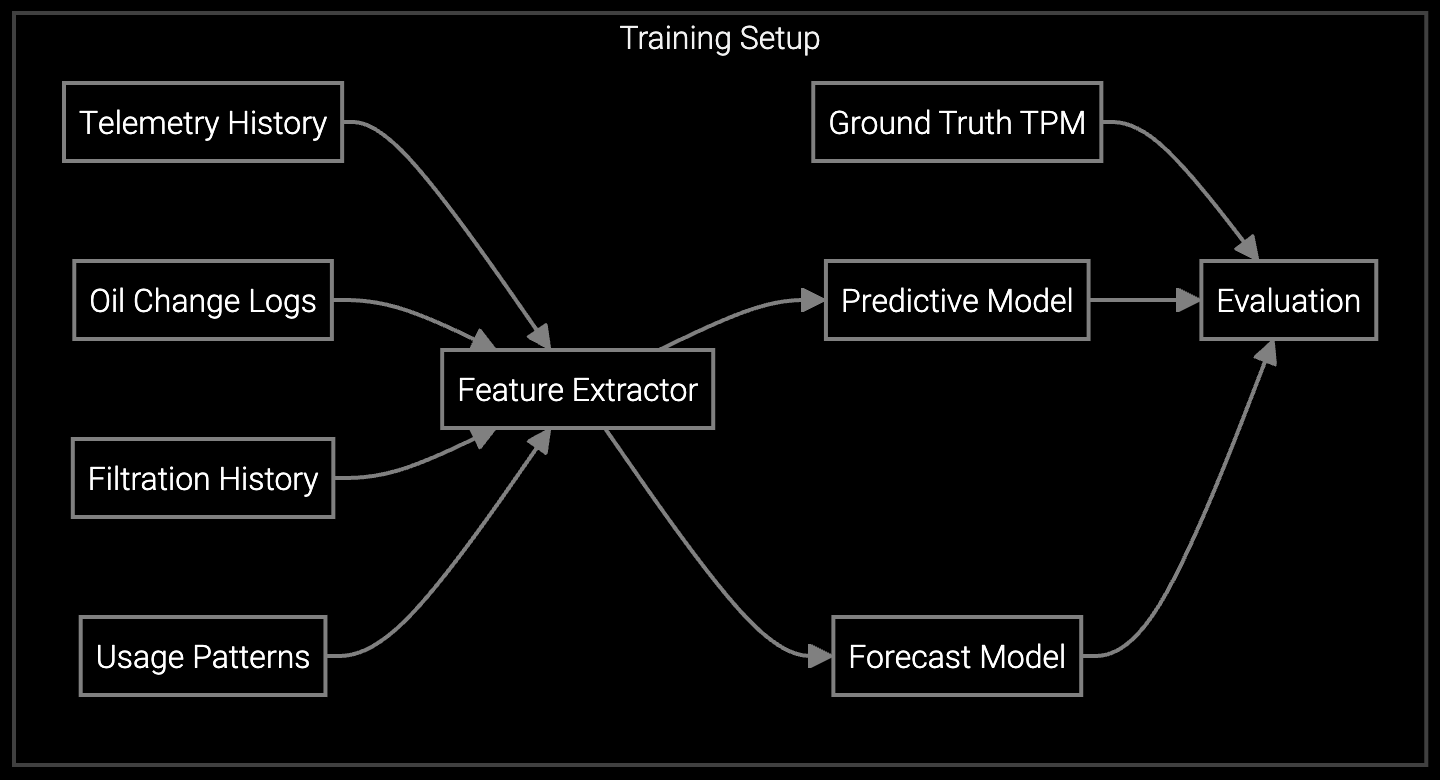

The platform ingests telemetry from PLCs, SCADA systems, and IoT sensors to automatically populate and update asset records. Pattern recognition algorithms identify serial numbers and configurations from historical service data, eliminating manual data entry. Configuration changes are detected in real-time and reconciled against system records, with discrepancies flagged for review.

The AI continuously monitors equipment health scores, usage patterns, contract expiration dates, and EOL/EOS timelines. When an asset approaches warranty expiration with declining performance metrics or exceeds usage thresholds indicating upgrade candidacy, the system surfaces the opportunity to sales teams with supporting data. Timing is calibrated 60-90 days before renewal deadlines to maximize conversion rates.

For equipment lacking IoT sensors or network connections, the platform reconciles service records, warranty claims, and parts order histories to infer asset state and configuration. Manual field reports and photos are processed through computer vision to extract serial numbers and equipment condition. While real-time monitoring requires connectivity, historical pattern analysis provides sufficient visibility for lifecycle planning and contract management on legacy assets.

Track administrative time saved through eliminated data entry, measured in FTE hours per quarter. Measure contract attachment rate improvement comparing pre- and post-automation periods. Calculate configuration drift reduction by tracking the percentage of assets with accurate records over time. Quantify upsell revenue from opportunities surfaced by the platform that would have otherwise expired without renewal. These metrics together demonstrate both cost reduction and margin protection.

The platform connects via APIs to SAP, Oracle, Salesforce, and other enterprise systems to synchronize asset records, contract data, and customer information. Workflow automation respects existing approval chains and escalation paths, triggering notifications in the tools your teams already use. Configuration changes detected by the AI are written back to your ERP system automatically, maintaining a single source of truth without duplicate data entry.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how automated workflows eliminate administrative costs while surfacing upsell opportunities before they expire.

Schedule Demo