Manual asset tracking can't scale when you're managing millions of appliances with decades-long lifecycles and fragmented registration data.

Appliance manufacturers automate asset tracking, configuration management, and contract renewal workflows by orchestrating AI across product registration, firmware versioning, and EOL planning—reducing manual data entry while improving contract attachment rates and proactive service visibility.

Missing serial numbers, unregistered products, and configuration gaps prevent proactive service. When customers call with issues, support lacks the equipment history needed for fast resolution.

Firmware updates, part replacements, and field modifications create discrepancies between recorded configurations and actual equipment state. This drives diagnostic errors and wrong-part orders.

Without visibility into contract expiration dates and equipment age, manufacturers lose service contract renewals and upsell opportunities. Revenue leaks through manual tracking gaps.

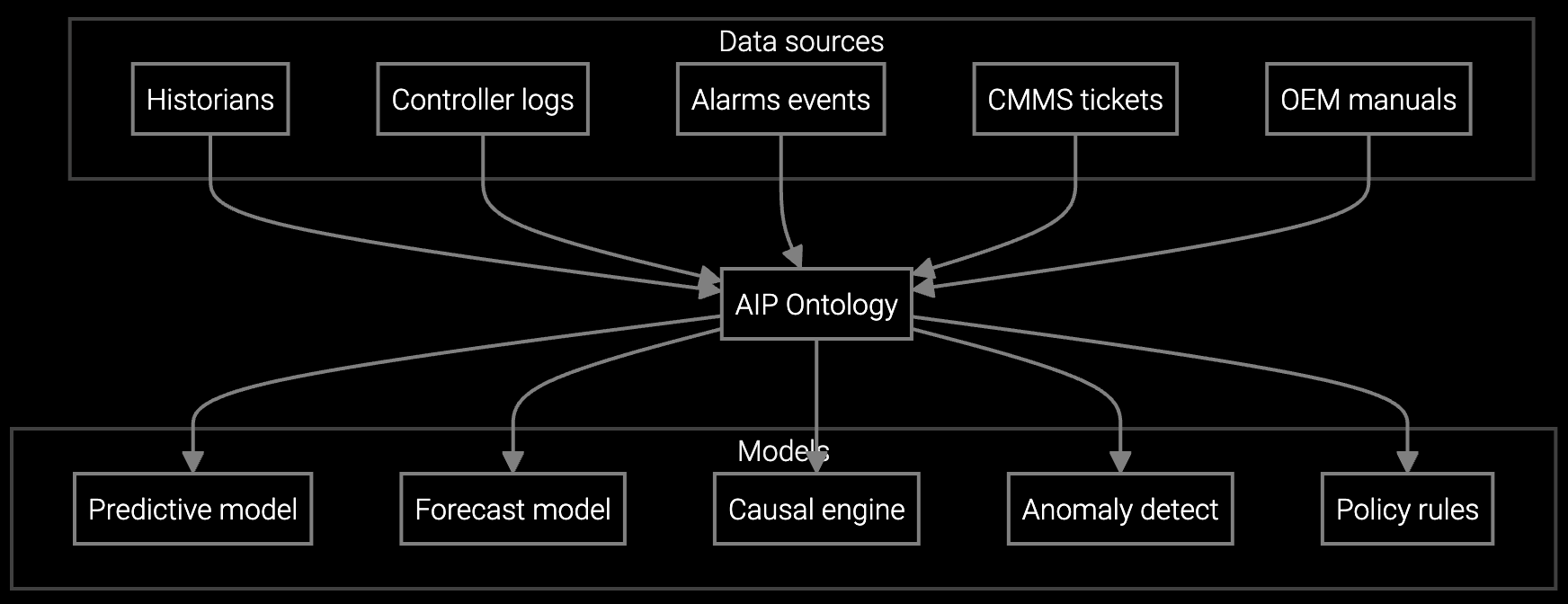

Bruviti orchestrates the entire installed base management workflow—from initial product registration through EOL tracking. The platform automatically enriches asset records by combining warranty registration data, IoT telemetry, service history, and firmware logs into a unified equipment profile. Configuration changes detected through connected appliance data trigger automatic record updates, eliminating manual reconciliation.

AI-driven lifecycle planning identifies contract renewal opportunities by analyzing equipment age, usage patterns, and failure probability. Automated EOL workflows flag products approaching end-of-support, generate customer notifications, and present upgrade paths tailored to each customer's installed base. This transforms installed base management from reactive record-keeping into strategic margin protection.

Monitor real-time appliance telemetry to detect anomalies before they trigger service calls, enabling proactive maintenance and reducing warranty claims.

Predict when refrigerator compressors or HVAC components will fail based on usage patterns, driving timely service contract renewals.

Automate maintenance scheduling for commercial kitchen equipment based on actual operating conditions rather than fixed time intervals.

Appliance manufacturers face unique installed base challenges: products with 10-20 year lifespans, high-volume consumer sales creating millions of asset records, and fragmented registration data from retail channels. Connected appliances generate IoT telemetry (temperature sensors, usage cycles, error codes) but legacy products remain visibility gaps.

Warranty cost control depends on accurate failure prediction across the installed base. When HVAC systems fail during summer peaks or refrigerators break during holidays, customers demand immediate resolution. Complete equipment history—purchase date, service records, firmware version, part replacements—enables faster diagnosis and right-part dispatch. Automated lifecycle tracking identifies service contract candidates before equipment reaches failure-prone age brackets, protecting margin through recurring revenue.

AI integrates warranty registration portals, IoT onboarding flows, and service event data to build asset records automatically. When customers register products online or connect appliances to WiFi, the platform captures serial numbers, model details, and purchase dates. Service calls and firmware updates enrich records over time, filling gaps without manual data entry.

Configuration updates from IoT telemetry, EOL status flagging based on product age, contract renewal candidate identification, and firmware version tracking run autonomously. The platform auto-updates asset records when connected appliances report software changes or part replacements. Human review focuses on renewal outreach strategy and upgrade recommendations, not data entry.

Complete asset visibility enables more accurate failure rate modeling. When the platform tracks actual equipment age, usage intensity, and configuration history across the installed base, finance can tighten warranty reserve estimates. Identifying high-risk product cohorts early allows targeted interventions—proactive part replacements or firmware updates—that reduce actual claims and improve reserve accuracy.

Yes. The AI maintains asset records across decades, flagging lifecycle milestones automatically. For non-connected products, service calls and warranty claims provide periodic data refresh points. The platform identifies when products enter high-failure age brackets, triggering proactive customer outreach even when years pass between service interactions.

Bruviti ingests existing asset databases and begins automated enrichment within weeks. Start with high-value product lines or connected appliances generating telemetry. The platform processes historical service records to backfill equipment history, then maintains records going forward. Full installed base coverage expands as additional product lines and data sources integrate over 3-6 months.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how AI-driven lifecycle automation improves contract attachment rates and reduces warranty exposure.

Schedule Demo