Missing serial numbers and configuration drift cost semiconductor OEMs millions in preventable downtime and missed service revenue.

Semiconductor OEMs solve incomplete asset data by unifying serial numbers, configuration states, and telemetry streams into a real-time digital twin registry that eliminates manual reconciliation and enables proactive lifecycle management at fab scale.

Lithography tools and etch systems operate with dozens of configuration parameters. When configuration drift goes undetected, fabs experience recipe failures that cascade through production lines.

Chamber kits, gas delivery modules, and metrology components lack consistent serial tracking. Service teams arrive on-site unable to confirm equipment history or warranty status.

Without visibility into equipment lifecycle status across installed base, service contracts expire unrenewed and upgrade opportunities go unidentified until customers call with failures.

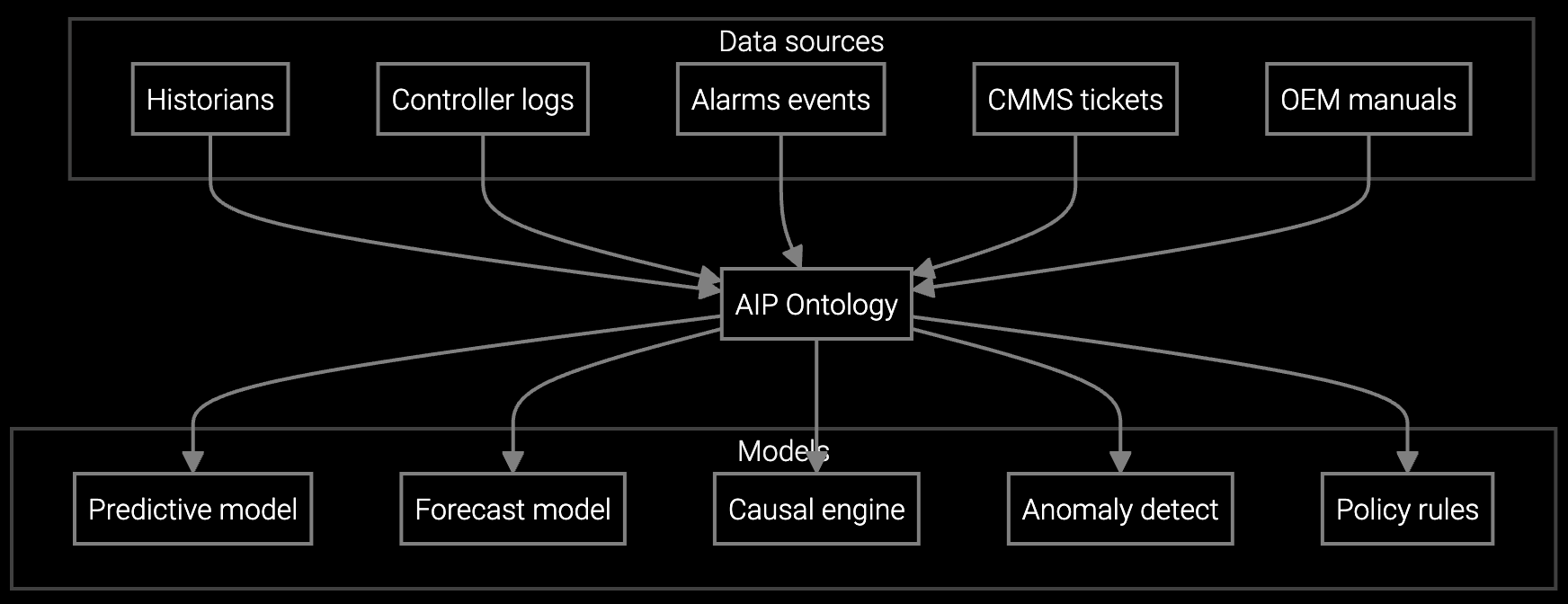

Bruviti ingests data from disparate sources—ERP systems, MES platforms, IoT telemetry, service records—and reconciles them into a single source of truth. Machine learning models identify equipment by matching partial serial numbers, configuration fingerprints, and sensor signatures even when legacy systems contain incomplete data.

The platform continuously monitors configuration drift by comparing actual equipment states against baseline records. When lithography recipe parameters deviate or chamber component usage exceeds thresholds, automated alerts trigger proactive maintenance before yield degradation occurs. Digital twins track remaining useful life for high-value consumables, enabling planned PM windows that minimize production impact.

Virtual models of lithography and etch tools track real-time performance against baseline parameters, enabling predictive maintenance before yield impact.

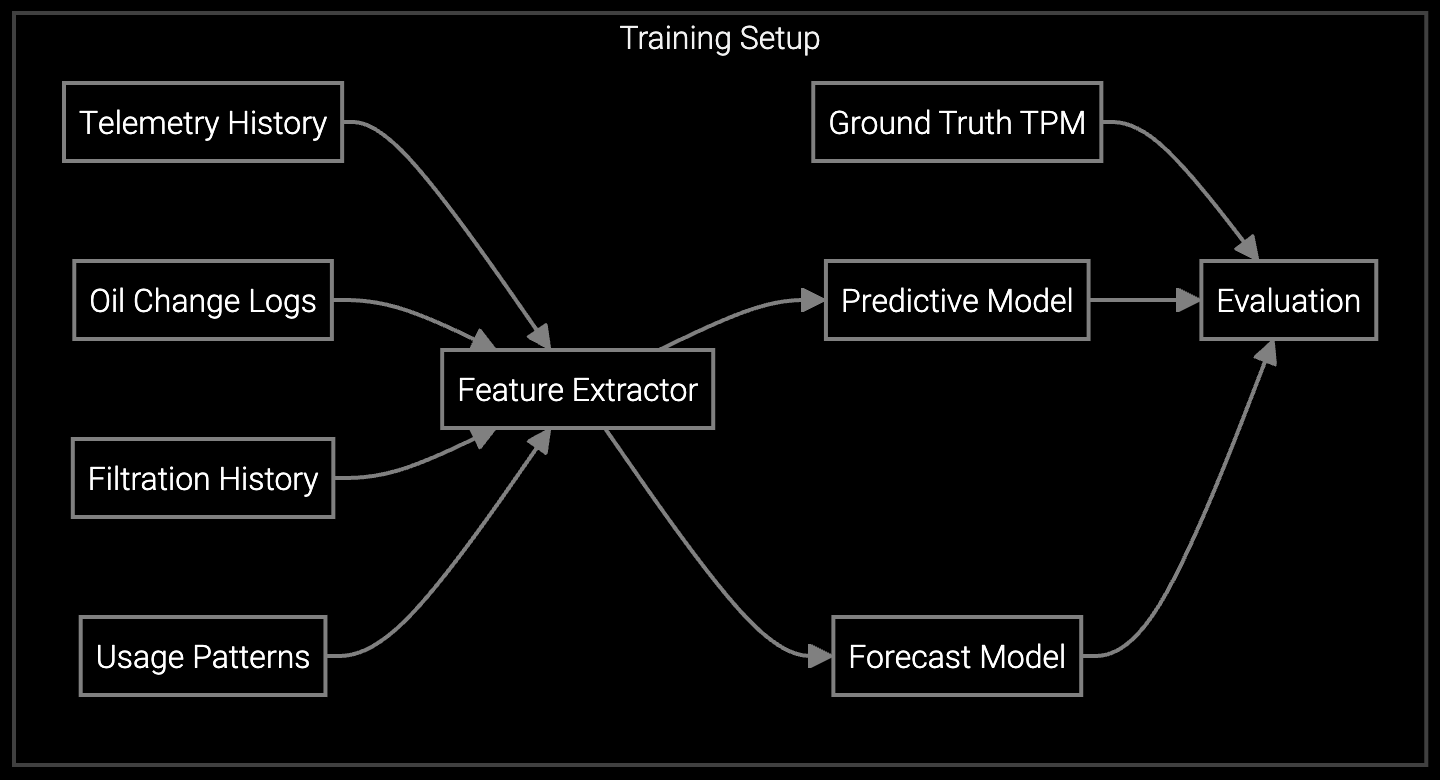

Analyzes telemetry streams from chamber sensors to identify pressure anomalies, temperature drift, and gas flow deviations before recipe failures occur.

Estimates chamber kit and consumable lifespan based on usage patterns, enabling planned maintenance windows that avoid costly emergency shutdowns.

Semiconductor equipment generates thousands of telemetry signals per tool. Bruviti's platform correlates process chamber sensor data with production metrology results to identify which configuration parameters drive yield variation. This enables service teams to optimize PM schedules based on actual equipment condition rather than fixed intervals.

For OEMs supporting multiple fabs globally, the platform aggregates asset data across sites to identify failure patterns by tool generation, process node, and operating environment. When a specific lithography scanner model shows accelerated lens degradation in high-humidity fabs, service leadership can proactively inspect sister tools before yield loss occurs.

Machine learning models match equipment using configuration fingerprints, sensor signatures, and partial identifiers. The system builds confidence scores by cross-referencing multiple data sources including service records, telemetry patterns, and installation dates. Human reviewers validate matches above 85% confidence; lower-confidence candidates surface for manual confirmation.

Most semiconductor OEMs reach 95% accuracy within 90 days for priority equipment classes. The platform ingests historical data in weeks, then continuously improves as it processes service events and telemetry. Lithography and etch tools typically achieve full accuracy first due to richer data streams; metrology equipment takes longer due to sparser records.

Digital twins track baseline configuration states for each tool. Real-time telemetry monitoring detects deviations in process parameters, chamber conditions, or consumable wear. When drift exceeds thresholds correlated with yield impact, automated alerts route to the appropriate service team with specific corrective actions before production runs fail.

Yes. The platform maps your installed base against product lifecycle databases to flag equipment nearing EOS dates. It prioritizes alerts based on business criticality—tools on critical process steps surface first. This enables proactive customer outreach for upgrade planning rather than reactive emergency replacements when parts become unavailable.

Bruviti connects to MES, FDC, ERP, and service management systems via standard APIs. For equipment telemetry, the platform ingests SECS/GEM streams or connects to existing IoT gateways. Most integrations complete in 4-6 weeks with no disruption to production operations. The platform operates as a read-mostly layer without modifying source systems.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how semiconductor OEMs achieve 95% asset accuracy and protect millions in service margin.

Schedule Demo