When fab managers call about tool failures, conflicting guidance from different agents turns hours into days of lost production.

Inconsistent agent responses create repeat contacts that delay fab recovery. AI-assisted knowledge retrieval gives every agent instant access to verified tool diagnostics, eliminating response variance and cutting escalations by 40%.

Fab managers call back because different agents gave conflicting guidance on the same lithography error code. Each repeat contact delays resolution while the tool sits idle.

Agents search through equipment manuals, past tickets, and internal wikis to answer process questions. The fab waits while agents hunt for answers across fragmented systems.

Junior agents escalate to senior engineers because they lack confidence in tool diagnostics. Engineering time gets consumed on issues agents could resolve with better knowledge access.

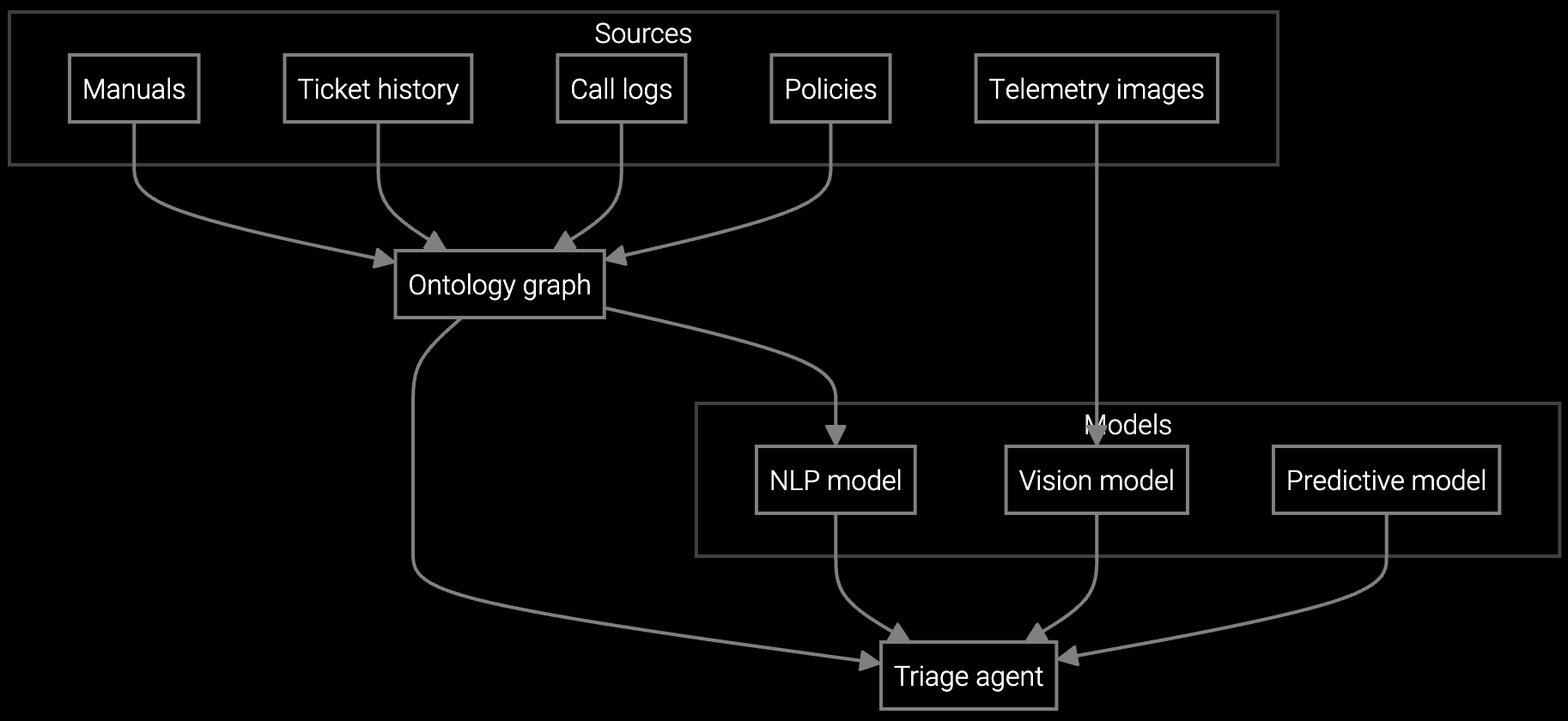

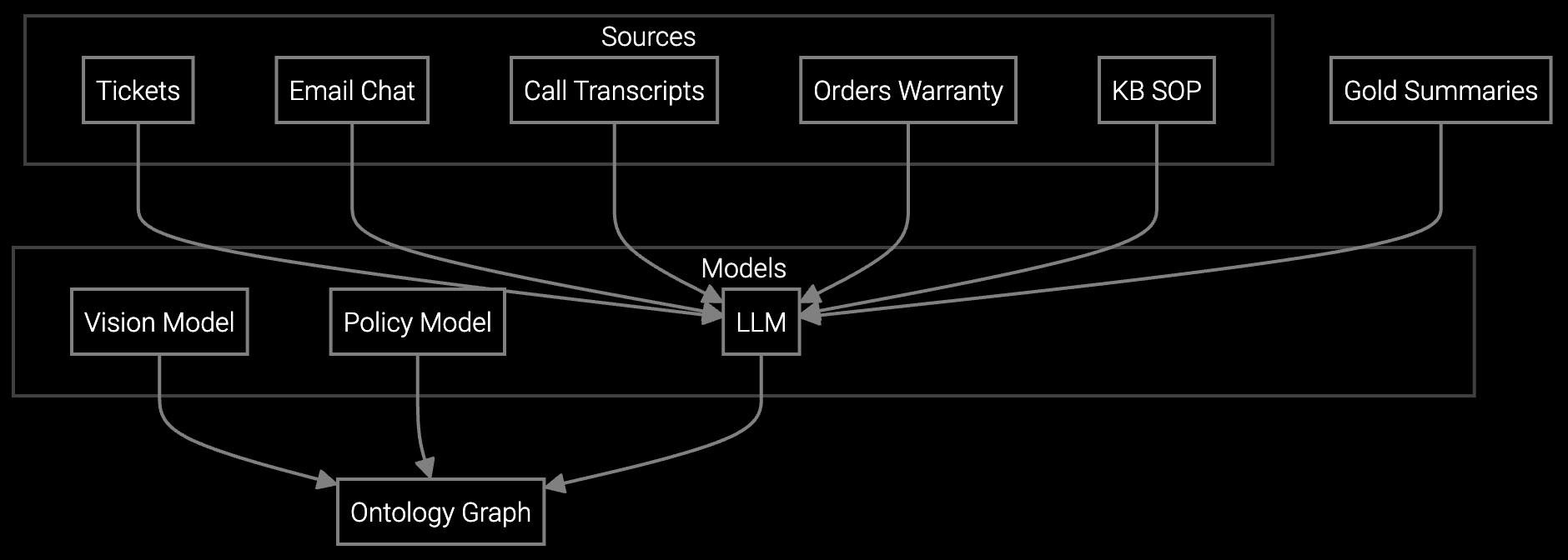

The platform ingests equipment manuals, historical case resolutions, and process engineer notes to build a unified knowledge base indexed by symptom, error code, and tool model. When a fab manager calls about chamber pressure drift, every agent sees the same verified diagnostic path ranked by success rate across your install base.

Real-time context retrieval surfaces the three most relevant resolutions based on tool configuration, process recipe, and failure signature. Agents deliver consistent guidance without searching multiple systems. The result: fab managers get reliable answers on the first call, agents resolve cases faster without escalating to engineering, and your cost per contact drops as handle time and repeat contacts decline.

Autonomous case classification analyzes tool symptoms, correlates chamber telemetry, and routes lithography issues to the right specialist with diagnostic context.

Instantly generates case summaries from fab manager emails, chat logs, and call transcripts so agents understand tool failure history without reading everything.

AI automatically reads fab manager emails about equipment issues, classifies by tool and severity, and drafts responses using verified resolution steps from your knowledge base.

Semiconductor fabs operate 24/7 with sub-5nm precision requirements where a single tool failure cascades through the production line. When a lithography system throws an error code, the fab manager needs immediate, reliable guidance. Conflicting responses from different agents on different shifts delay recovery and amplify downtime costs.

Equipment complexity makes knowledge retrieval challenging. Agents must correlate error codes with process recipes, chamber configurations, and maintenance history across multiple tool models. Without unified access to verified diagnostics, agents give inconsistent answers, fab managers call back, and engineering time gets consumed on issues that should be resolved at Tier 1.

Equipment complexity and knowledge fragmentation create response variance. Agents search through manuals, past tickets, and wikis to answer process questions, but different agents find different answers or interpret the same information differently. Without unified access to verified diagnostics, agents give conflicting guidance on the same tool failure, causing fab managers to call back and delaying resolution.

The platform indexes equipment manuals, historical case resolutions, and process engineer notes into a unified knowledge base searchable by symptom, error code, and tool model. When an agent receives a call, the system surfaces the three most relevant resolutions ranked by success rate. Every agent sees the same verified diagnostic path, eliminating response variance and reducing repeat contacts by 40%.

Premature escalations consume senior engineering time on routine issues agents could resolve with better knowledge access. When 38% of cases escalate unnecessarily, engineering capacity gets diverted from complex failures and yield improvements to answering basic tool questions. AI-assisted retrieval reduces escalations by 40%, freeing engineering for high-value work while lowering cost per contact.

Measurable impact appears within 60 days of deployment. Track three metrics: escalation rate should drop 30-40%, average handle time should decrease 2-3 minutes per call, and first contact resolution should improve 25-30%. These translate directly to cost per contact reduction and fab recovery time improvements visible in quarterly reporting.

The system ingests equipment manuals, historical case tickets, and process engineer documentation to build the knowledge base. Enriching with chamber telemetry, error logs, and maintenance records improves diagnostic accuracy. Integration with your CRM and ticketing system ensures agents access verified resolutions within their existing workflow without switching applications.

Transforming appliance support with AI-powered resolution.

Understanding and optimizing the issue resolution curve.

Vision AI solutions for EV charging support.

See how AI-assisted knowledge retrieval delivers consistent agent responses and reduces escalations by 40%.

Schedule Executive Briefing