NFF returns drain warranty reserves and erode customer trust—yet 40-60% stem from configuration issues, not hardware defects.

High NFF rates in network equipment returns stem from configuration issues misdiagnosed as hardware failures. AI analyzes device logs, configuration state, and failure patterns to separate true hardware faults from firmware bugs or misconfiguration before authorizing RMA, reducing unnecessary returns by 40-60%.

Manual warranty lookups against fragmented serial number databases and contract records delay RMA authorization. Network OEMs managing thousands of SKUs across multiple firmware branches face 2-4 day verification cycles per claim.

Customer-reported "failures" often mask configuration drift, incompatible firmware combinations, or known CVE-related bugs. Without automated log analysis, RMAs are authorized for devices where remote remediation would resolve the issue.

Every NFF unit consumes return shipping, receiving inspection, test bench time, and restocking labor. For carrier-grade equipment with 6-8 week lead times, unnecessary returns create phantom stockouts that trigger emergency procurement.

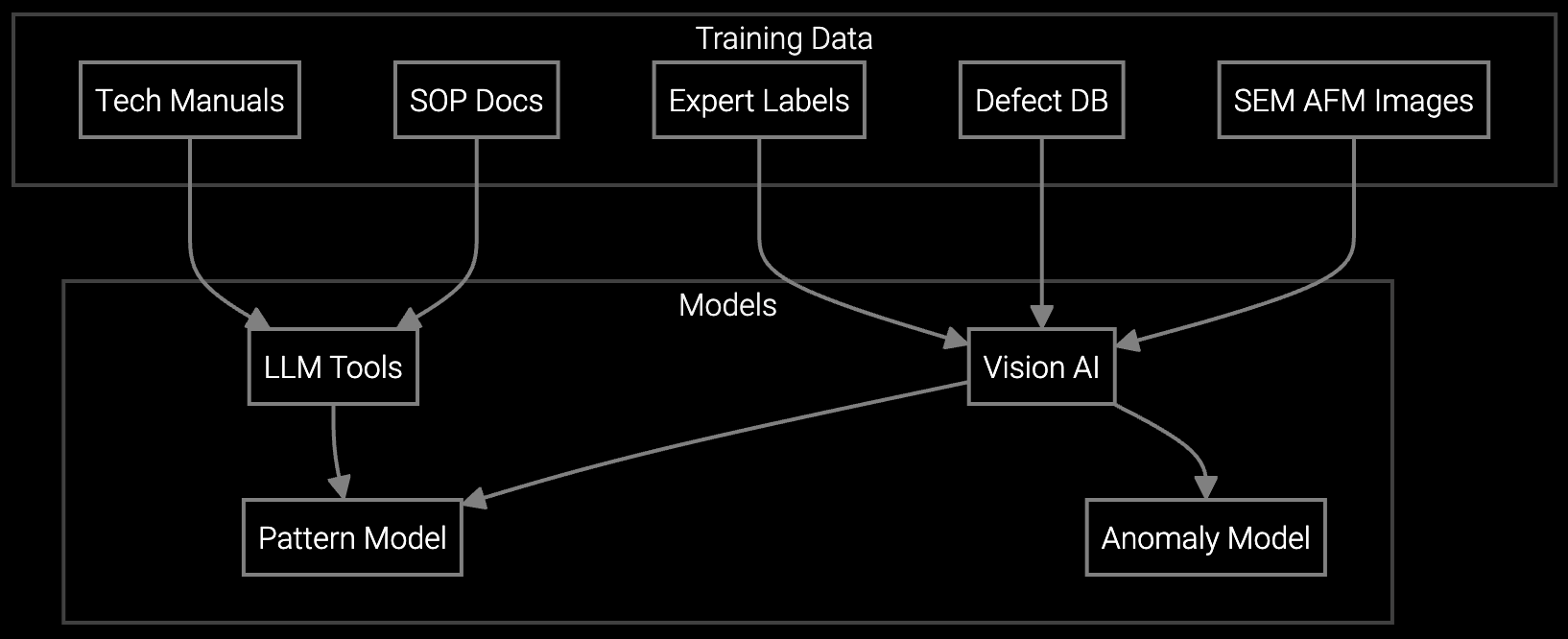

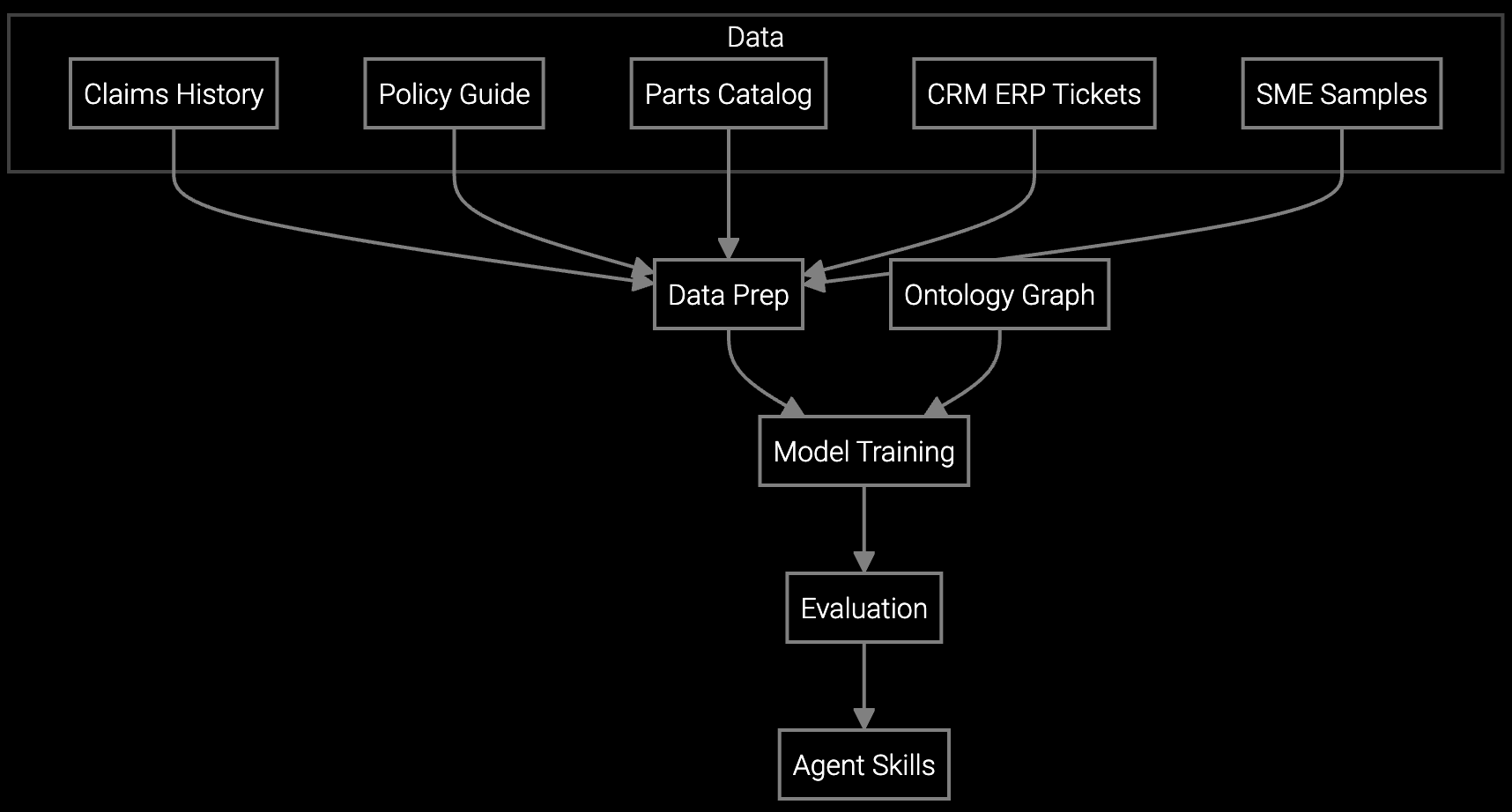

Bruviti's API-first platform ingests syslog streams, SNMP trap data, and device configuration snapshots via standard protocols. The system parses multi-vendor log formats (Cisco IOS, Juniper JunOS, Arista EOS) and correlates error sequences against known failure signatures. Before authorizing an RMA, the fraud detection model checks for configuration anomalies, firmware version mismatches, and patterns consistent with user error rather than hardware defects.

For builders, the Python SDK exposes entitlement lookup, claims validation rules, and NFF prediction endpoints. Custom models can be trained on your historical RMA data to detect fraud patterns unique to your customer base. The platform integrates with SAP for warranty entitlement and Oracle for return logistics—no vendor lock-in, just headless APIs that plug into your existing stack.

For network ASICs and optical transceivers, AI analyzes microscopic failure images to validate hardware defects vs. electrical overstress or ESD damage, reducing invalid warranty claims.

Automatically classifies network equipment claims by failure mode (power supply, fan module, firmware corruption) and assigns warranty codes, eliminating manual review delays.

Network infrastructure operates under 99.999% uptime SLAs where every minute of downtime costs customers thousands in lost transactions. When a router or switch is RMA'd unnecessarily, the customer experiences a false alarm that erodes trust in the equipment's reliability. Meanwhile, the OEM pays for reverse logistics, refurbishment labor, and replacement shipments—all for a device that was never defective.

For carrier-grade equipment with 12-18 month lead times, NFF returns also create artificial inventory shortages. A firewall returned for "packet loss" but later found to have a BGP misconfiguration ties up critical stock that could serve a real hardware failure. This drives warranty reserve bloat and emergency procurement costs that destroy margin on long-tail SKUs.

Most NFF returns stem from configuration drift, incompatible firmware versions, or known bugs misidentified as hardware failures. A router flagged for "packet loss" may have BGP route flapping due to a neighbor misconfiguration. Without automated log analysis, these software issues trigger unnecessary RMAs that waste warranty reserves and tie up inventory.

The platform parses syslog and SNMP trap data to identify error sequences consistent with hardware failure (e.g., thermal shutdown events, fan RPM anomalies) versus configuration problems (e.g., VLAN mismatches, authentication failures). It cross-references device firmware version against known CVE databases and correlates reported symptoms against historical RMA outcomes to predict whether remote remediation will resolve the issue.

Yes. The Python SDK exposes model training endpoints where you can upload historical claims data with ground-truth labels (NFF vs. valid defect). The platform supports transfer learning from Bruviti's pre-trained network equipment models, so you get accuracy with less training data. Models are stored in your infrastructure—no data leaves your environment unless you explicitly push updates to the hosted API.

Core dependencies include ERP integration for serial number and warranty entitlement lookup (SAP, Oracle) and syslog/SNMP feed access from your NOC monitoring stack. Optional enhancements include linking to your knowledge base (Confluence, ServiceNow) for firmware bug references and connecting to return logistics systems (RMA portals, 3PL APIs) for automated disposition routing.

Pilot deployments typically show measurable NFF reduction within 30-60 days. The system needs 2-4 weeks to ingest historical claim data and calibrate prediction thresholds, followed by 4-6 weeks of live RMA decisions to validate accuracy. Full-scale rollout across all product lines takes 3-6 months depending on the number of SKUs and firmware branches you support.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how Bruviti's API-first platform integrates with your warranty systems to cut unnecessary returns and protect margin.

Talk to a Solutions Architect