Warranty reserves now threaten margins as hyperscale deployment cycles shorten and NFF returns spike from thermal complexity.

Data center OEMs reduce warranty reserves through AI-driven claims validation, NFF detection, and fraud prevention—deployed as modular APIs integrated with existing systems or managed services requiring minimal technical lift.

Data center OEMs face unpredictable warranty costs as complex thermal interactions and firmware issues create spikes in claims. CFOs struggle to forecast reserves accurately when failure patterns shift with each hardware generation.

Server and storage OEMs absorb the full cost of processing, testing, and restocking components that show no defects upon inspection. Each NFF return costs the full replacement value plus logistics and labor without identifying root cause.

Manual claims review misses patterns indicating invalid returns—equipment swaps, false failure reporting, and out-of-entitlement submissions. Each undetected fraudulent claim costs the replacement value plus processing overhead.

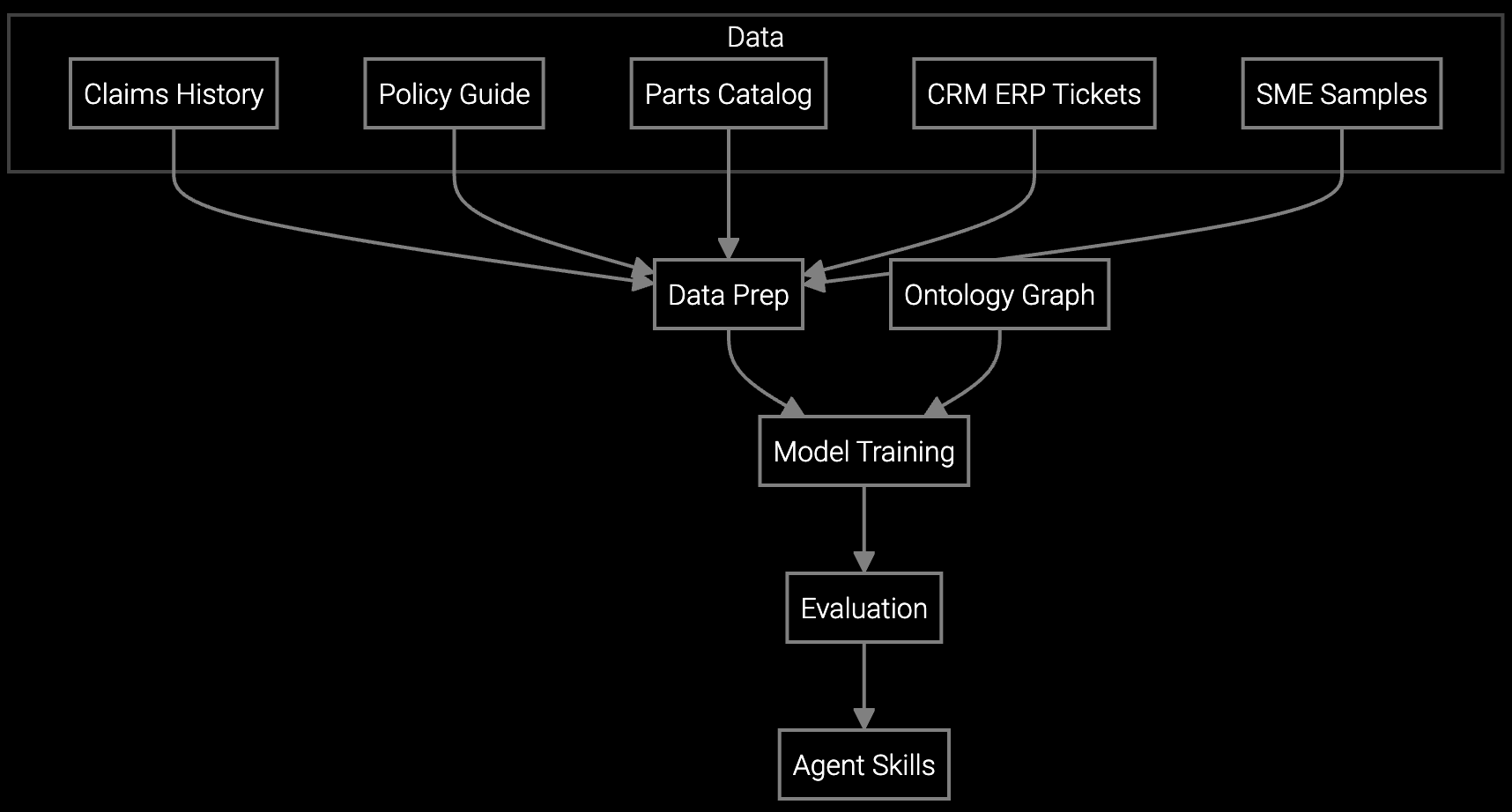

Data center equipment manufacturers face a strategic choice: build proprietary AI models for warranty intelligence, purchase closed vendor platforms, or deploy modular AI integrated with existing ERP and RMA systems. The decision hinges on speed to margin impact, technical control, and avoiding platform dependencies that constrain future flexibility.

Bruviti provides pre-trained models for claims validation, NFF prediction, and fraud detection accessible via REST APIs—preserving existing warranty workflows while adding intelligence layers. The platform learns from BMC telemetry, firmware logs, and historical claims patterns without requiring data migration or system replacement. Integration teams retain control over entitlement rules, approval workflows, and business logic while leveraging domain-trained AI that recognizes data center failure modes.

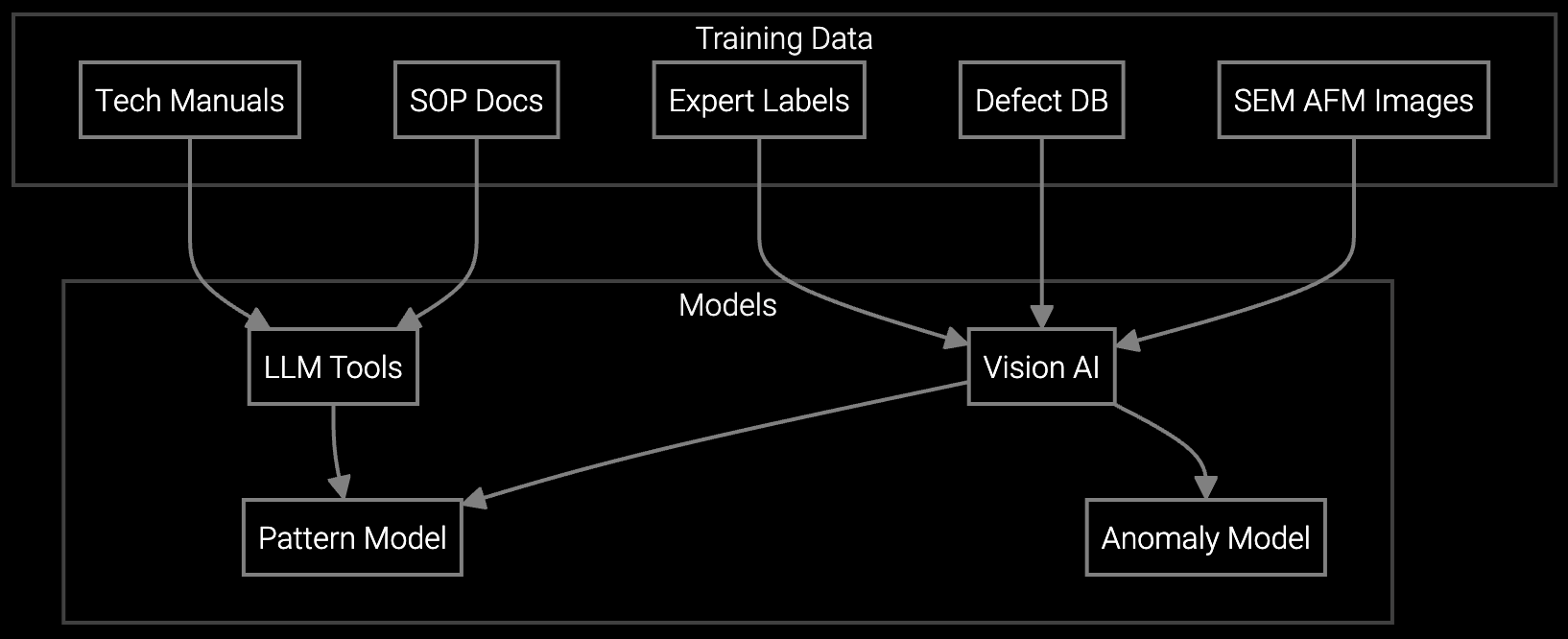

Analyze microscopic images of returned server components to identify thermal stress patterns, validate failure claims, and reduce NFF rates for high-value memory and storage returns.

Automatically classify warranty claims by failure mode and route to appropriate review teams, reducing manual triage time for high-volume server and cooling equipment returns.

Data center OEMs manage warranty operations across server generations, storage platforms, cooling systems, and power infrastructure—each with distinct failure modes and thermal sensitivities. AI learns from BMC telemetry, IPMI logs, and environmental sensors to predict which returned components will test as NFF based on operating history before the claim was filed.

Claims validation integrates with entitlement databases to verify warranty status, match serial numbers against deployment records, and flag inconsistencies indicating equipment swaps or false reporting. The platform recognizes data center-specific failure patterns—hot aisle thermal stress, power supply degradation, drive wear from high I/O workloads—reducing the rate of valid components rejected and invalid claims approved.

Data center OEMs typically see measurable NFF reduction within 60-90 days after integrating telemetry-based claims scoring. The AI analyzes BMC logs, thermal data, and operating history to predict which returns will test as valid defects versus configuration issues or customer-induced failures before shipping replacement components.

BMC telemetry, IPMI event logs, firmware crash dumps, and deployment configuration data provide the strongest signals for claims validation. Server OEMs that integrate these data sources with historical RMA outcomes achieve 82-89% accuracy in predicting NFF returns before authorizing replacements.

Integration preserves existing warranty workflows while adding intelligence layers. API-based platforms connect to ERP, RMA, and entitlement systems without requiring data migration or process redesign. This approach delivers faster deployment and avoids the risk of disrupting established claims operations.

Track warranty cost as percentage of revenue, NFF rate by product line, claims processing cycle time, and fraud detection rate. Data center OEMs typically target 20-30% reduction in warranty reserves and 40-60% improvement in claims processing speed as primary ROI metrics within the first year.

API-first architecture with standard REST interfaces ensures models integrate with any RMA or ERP system. Data remains in the OEM's control, model training uses the manufacturer's historical claims data, and business logic for approvals and entitlement verification stays within existing systems rather than migrating to vendor platforms.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how Bruviti reduces NFF rates and fraud losses for data center equipment manufacturers.

Schedule Strategy Session