Manual processing costs industrial OEMs 3-5% of revenue annually while equipment lifecycles stretch decades.

AI orchestrates warranty claims end-to-end: automated entitlement verification, fraud detection, NFF analysis, and RMA generation. Reduces manual processing by 70% while cutting warranty reserves through systematic validation.

Industrial equipment with 10-30 year lifecycles creates unpredictable warranty exposure. Without systematic fraud detection and NFF reduction, reserves balloon while margins shrink.

Operators return heavy machinery for warranty replacement without proper diagnostics. OEMs shoulder reverse logistics costs, refurbishment labor, and parts waste when equipment tests fine.

Manual entitlement verification and RMA generation delays customer replacements. Each claim requires lookups across warranty databases, parts systems, and service histories spanning decades.

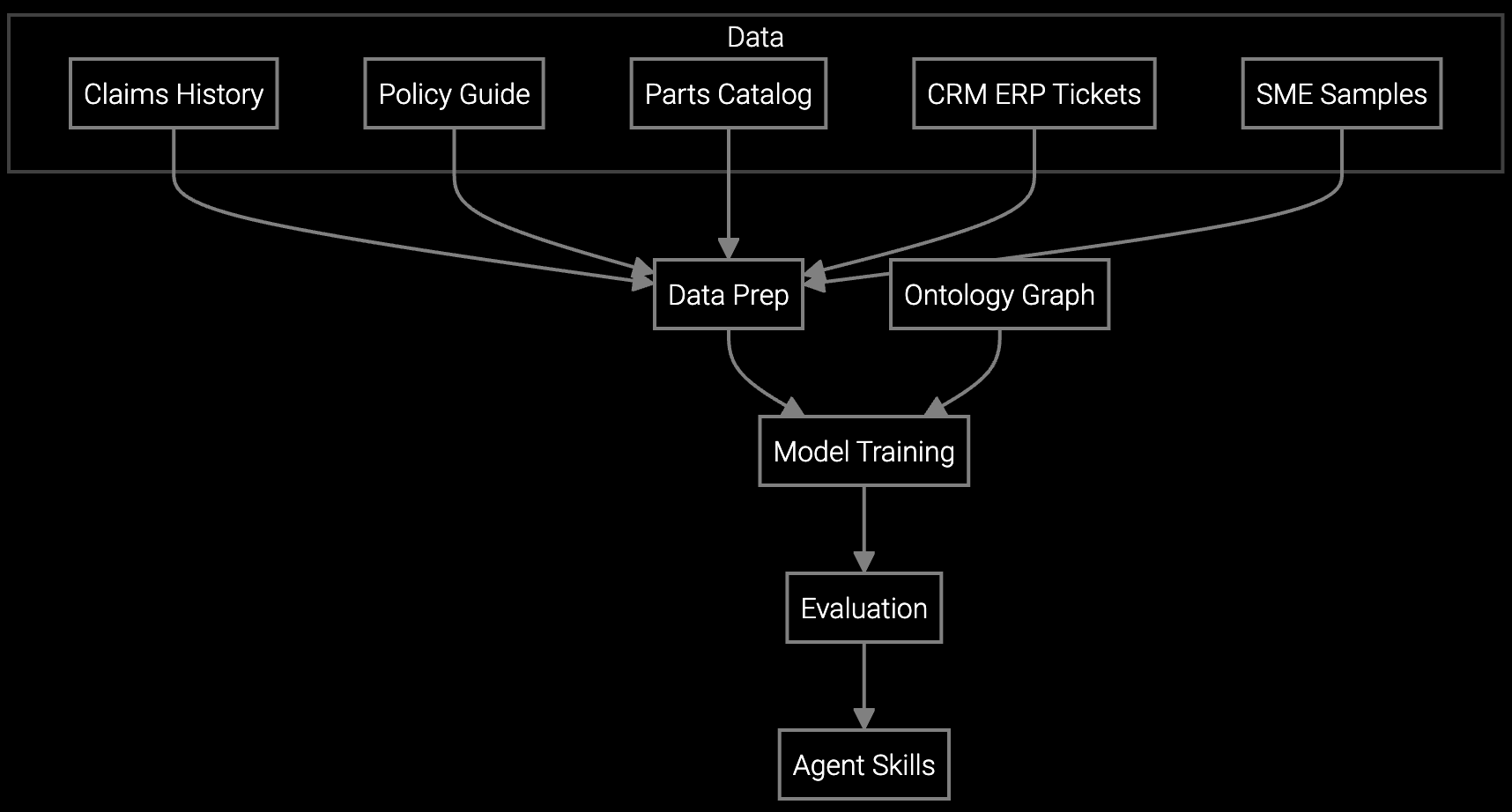

Bruviti orchestrates the entire warranty claims lifecycle autonomously. When a claim arrives, the platform instantly verifies entitlement against decades of equipment registration data, flags fraud patterns based on historical returns, analyzes sensor logs to diagnose No Fault Found conditions, and auto-generates RMAs with appropriate disposition codes. The AI executes what previously required five handoffs across warranty, engineering, and logistics teams.

The platform ingests decades of claims history, refurbishment outcomes, and sensor telemetry to identify valid versus invalid returns before they enter reverse logistics. For industrial machinery with 10-30 year lifecycles, this historical learning prevents warranty reserve erosion while accelerating legitimate replacements. Division leaders protect margins without adding headcount to adjudicate thousands of monthly claims.

Automatically classifies industrial equipment claims by failure mode, assigns disposition codes, and routes to appropriate refurbishment workflows based on decades of historical outcomes.

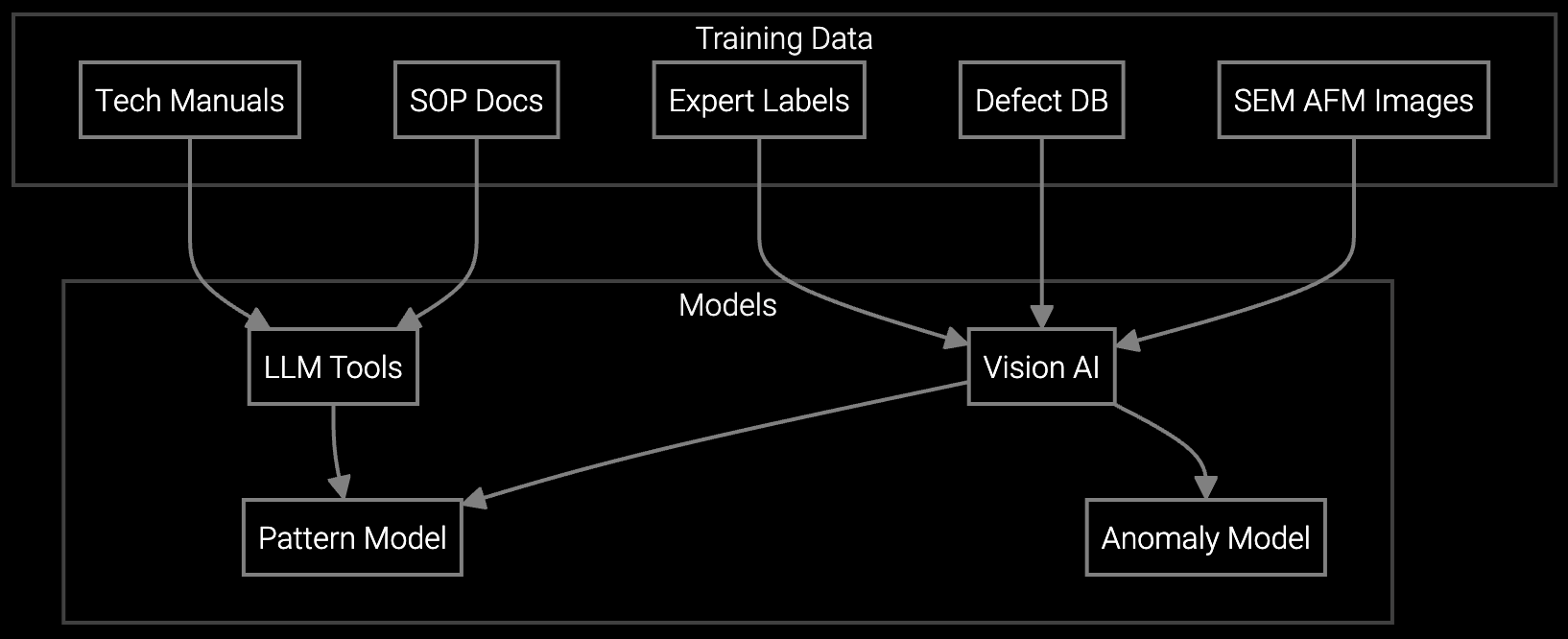

AI analyzes component imagery to validate warranty claims for heavy machinery, identifying legitimate material defects versus operator misuse or normal wear patterns.

Industrial OEMs support CNC machines, turbines, pumps, and automation systems deployed globally for 10-30 years. Equipment configurations evolve through retrofits and upgrades, making entitlement verification and parts eligibility complex. Operators run machinery in harsh conditions with varying maintenance quality, creating legitimate warranty claims alongside preventable failures and outright fraud.

The platform ingests warranty registration data, service histories, parts replacement records, and sensor telemetry spanning decades. When a claim arrives for a 15-year-old compressor, the AI instantly verifies entitlement, cross-references previous failures, analyzes vibration and temperature logs to validate the claimed failure mode, and determines whether the issue stems from defect versus deferred maintenance. This prevents invalid returns while accelerating legitimate replacements.

The platform analyzes sensor data, service histories, and claims patterns to identify returns likely to test fine upon receipt. By flagging probable NFF cases before reverse logistics, OEMs can request additional diagnostics or guide operators through troubleshooting, preventing unnecessary shipments of heavy machinery and refurbishment costs.

AI identifies claims from serial offenders, mismatches between claimed failure modes and sensor evidence, parts returned outside warranty windows with altered serial numbers, and returns from operators with poor maintenance compliance. These fraud signals trigger manual review before approving RMAs, protecting warranty reserves.

Industrial OEMs typically achieve 70% reduction in processing time within 90 days of deployment. Simple claims with clear entitlement and valid failure evidence process in minutes versus days, while complex cases receive prioritized routing to analysts with full context already assembled by AI.

Yes. The platform ingests warranty records, parts databases, and service histories regardless of age or format. For 20-year-old turbines or CNC machines, the AI synthesizes fragmented records across multiple systems to verify entitlement and assess claim validity, eliminating manual archeology through legacy databases.

Track warranty cost as percentage of revenue, NFF rate, claims processing cycle time, and warranty reserve accuracy. Division leaders quantify margin protection by showing reserve reduction from fraud prevention and NFF elimination, while demonstrating headcount efficiency through autonomous adjudication of routine claims.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how Bruviti reduces claims processing costs while cutting warranty reserves through systematic validation.

Schedule Executive Briefing