When every lithography tool costs $150M and downtime runs $1M per hour, incomplete asset data isn't just inefficient—it's existential.

Deploy AI asset tracking by connecting your ERP and MES systems via REST APIs, enabling automatic serial number capture from FOUP handlers and lithography tools, then configure anomaly alerts for configuration drift detection across your fab's installed base.

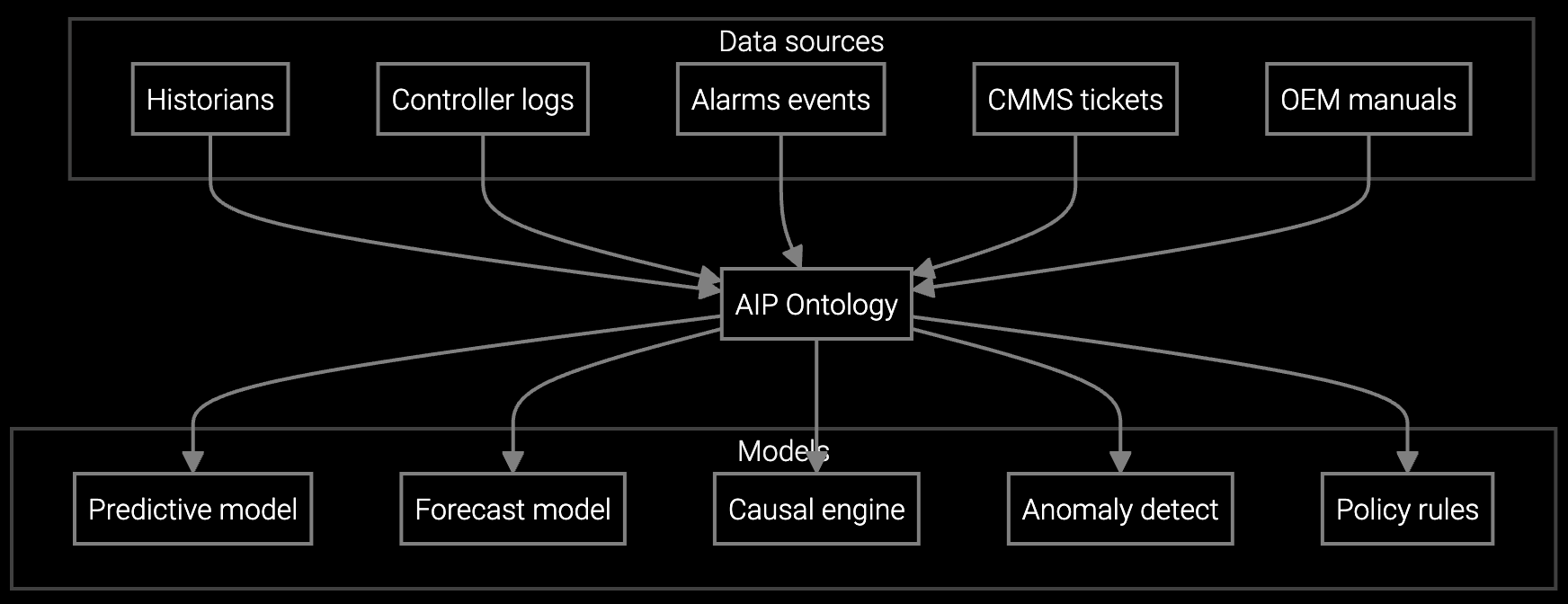

Asset records scatter across ERP, MES, CMMS, and legacy fab automation systems. No single view of what's installed, where, or in what configuration.

Process engineers update chamber recipes and software versions, but those changes don't flow back to asset records. Configuration drift goes undetected until it causes yield loss.

When a tool underperforms, you can't see its full service history, past configuration changes, or parts replacement timeline. Every investigation starts from scratch.

Start with API integration to your existing systems. Bruviti connects to ERP, MES, and CMMS via REST endpoints, pulling serial numbers, installation dates, and current configurations into a unified asset registry. The platform normalizes data across different schemas, so lithography tools from ASML, etch systems from Lam, and metrology equipment from KLA all appear in consistent format.

Configure automatic capture rules for equipment telemetry. The platform monitors SECS/GEM streams from fab tools, detecting configuration changes in real time. When a process engineer updates a chamber recipe or installs a firmware patch, the asset record updates automatically. Set anomaly thresholds to flag unexpected drift—like a tool running a different recipe than its assigned process—before it affects yield.

Monitors telemetry from lithography, etch, and deposition tools to identify anomalies before they cascade into yield loss.

Predicts when chamber kits, RF generators, and pumps will fail based on usage patterns and sensor trends.

Schedules PM windows during planned downtime, avoiding unplanned tool outages that halt wafer production.

Semiconductor fabs run on SECS/GEM protocols, EDA tool integration, and strict clean room access controls. The platform deploys as an edge appliance inside your fab network, eliminating cloud data transfer concerns. It speaks native SECS/GEM to tools, REST to ERP systems, and provides a single web interface for equipment tracking.

Start with a single bay of critical tools—lithography or etch—where configuration drift has the highest yield impact. Capture baseline configurations, then monitor for unauthorized changes. Once validated, expand to the full fab floor, tracking 200+ tools across multiple process steps without adding IT overhead.

Bruviti connects to ERP systems like SAP and Oracle, MES platforms like Applied's AutoMod and Promis, CMMS tools like Maximo, and directly to fab equipment via SECS/GEM interfaces. Pre-built connectors support Applied Materials, ASML, Tokyo Electron, Lam Research, and KLA tools.

Pilot deployment for a single process bay takes 2-3 weeks, including API configuration, equipment connection, and baseline data capture. Full fab rollout across 200+ tools typically completes in 6-8 weeks, depending on system integration complexity and clean room access schedules.

Yes. The platform monitors SECS/GEM telemetry and MES recipe updates in real time, automatically logging configuration changes to the asset record. You can set approval workflows requiring change tickets before recipe modifications take effect, preventing unauthorized drift.

The platform deploys as an on-premise edge appliance inside your fab network, with no cloud data transfer required. All processing happens locally, meeting semiconductor industry security and IP protection requirements. Optional cloud sync is available for multi-site visibility.

Most users require 1-2 hours of training to navigate the web interface and run standard queries. The platform surfaces asset data through a single search bar—no complex queries or system switching. Process engineers receive additional training on configuration approval workflows and anomaly alerting.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how Bruviti integrates with your existing systems in a 30-minute technical walkthrough.

Schedule Demo