When fab downtime costs $1M per hour, your contact center can't afford slow triage or inconsistent responses.

Deploy AI for semiconductor customer service by integrating case routing with equipment telemetry, training models on process-specific troubleshooting scenarios, and connecting to fab workflow systems to automate triage while maintaining production context.

Equipment telemetry lives in one system, case history in another, knowledge bases in a third. Agents manually correlate across platforms while customers wait. Recipe-specific troubleshooting requires context that legacy CRM systems can't surface.

Lithography issues require different troubleshooting than etch or deposition problems. Generic AI training can't distinguish between recipe drift and chamber contamination. Your contact center needs models trained on your equipment's failure modes.

Existing ticketing systems weren't built for real-time equipment data. Connecting AI routing to fab workflow tools requires custom integration. IT teams face months-long deployment timelines that delay ROI and increase executive risk.

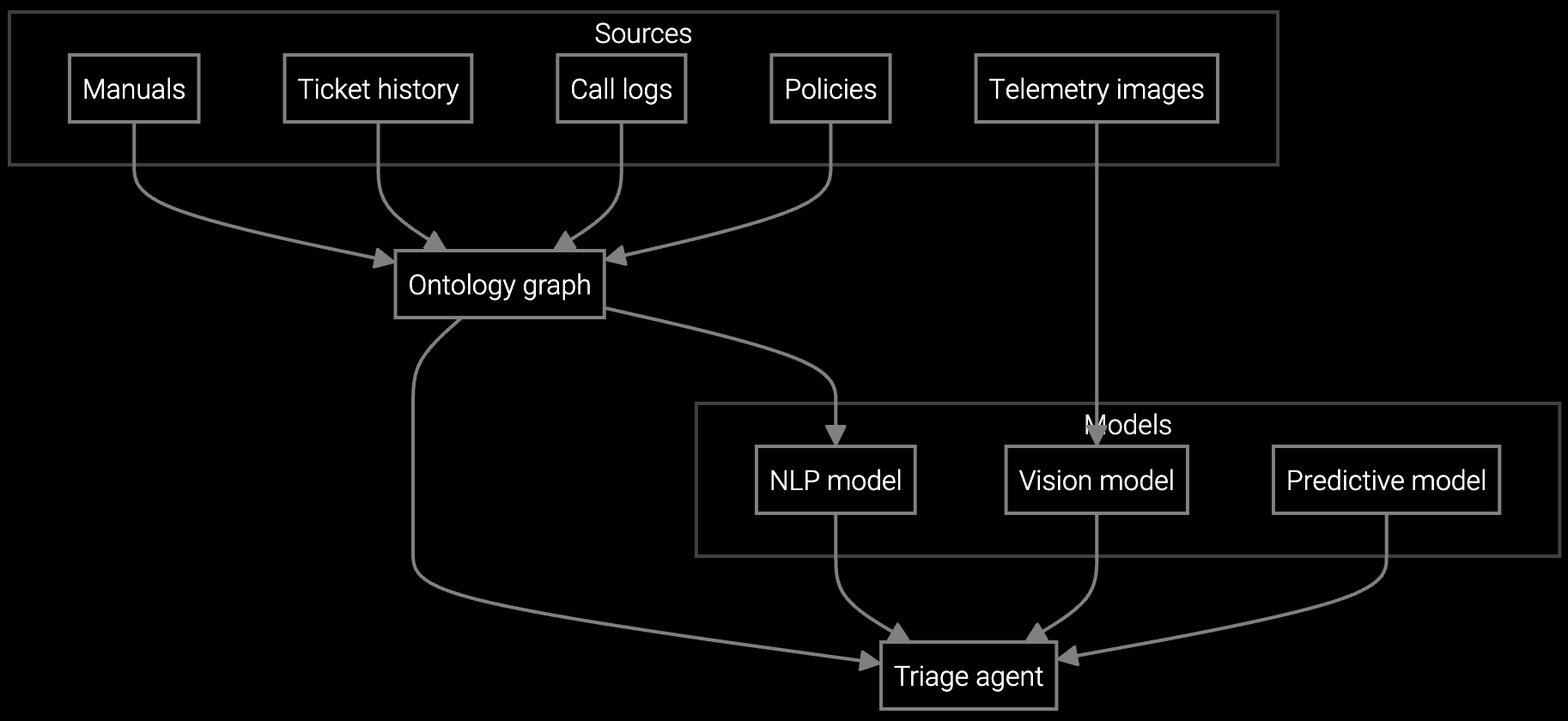

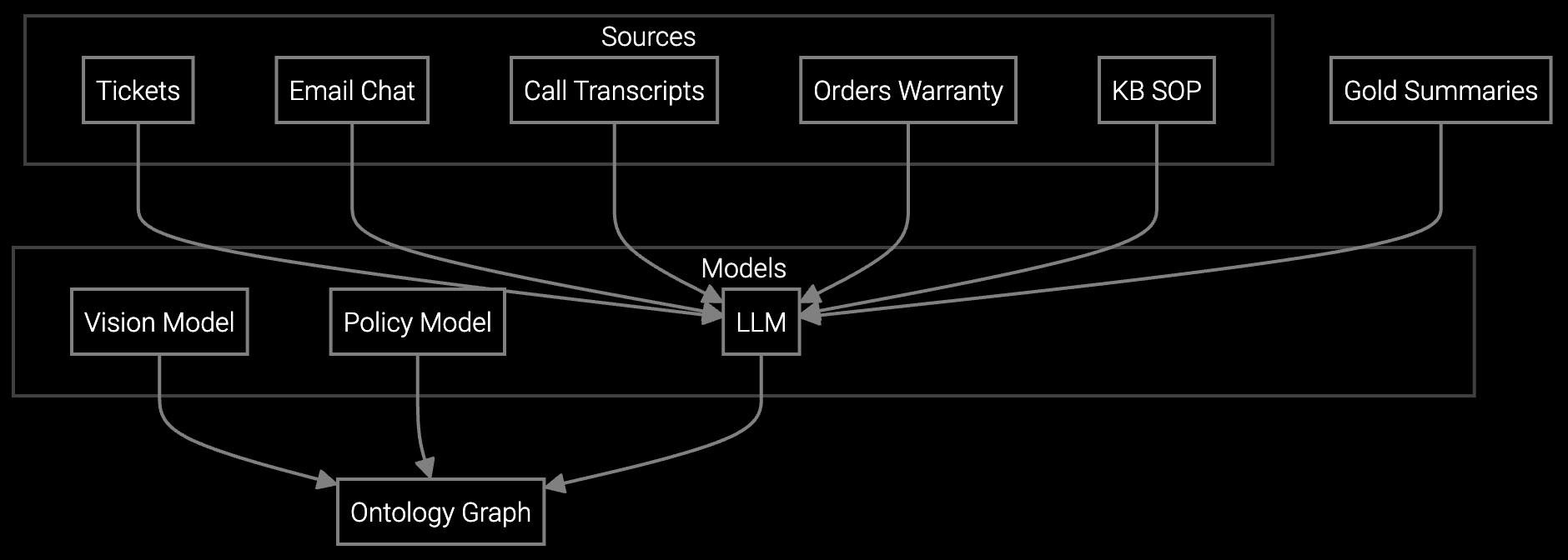

Bruviti's platform connects directly to your existing CRM and ticketing infrastructure through API-first integration. The system ingests historical case data, equipment telemetry feeds, and process documentation to train models specific to your product line. This means lithography support cases automatically surface chamber performance data, while etch tool issues pull relevant recipe parameters.

The architecture prioritizes operational continuity. Deploy incrementally by function—start with email triage, expand to chat routing, then add voice integration. Your agents work within existing tools while AI handles classification, context retrieval, and response drafting. When a fab engineer opens a case, the system has already correlated symptom patterns with similar historical failures and prepared diagnostic steps.

Autonomous classification correlates fab equipment symptoms with historical failure modes to route lithography, etch, and metrology issues to specialized teams with diagnostic context.

Instantly generates case histories from equipment logs, engineer emails, and chat transcripts so agents understand chamber performance trends without reading through weeks of documentation.

AI reads incoming fab engineer emails, classifies by equipment type and symptom category, and drafts responses using process-specific troubleshooting knowledge bases.

Semiconductor equipment OEMs serve fab customers where every minute of unplanned downtime represents massive revenue loss. Your contact center handles cases ranging from routine PM scheduling to emergency lithography system failures affecting entire production lines. The urgency spectrum is extreme—a metrology tool calibration question has days of tolerance, while a CVD chamber temperature deviation demands resolution within the hour.

Your agents need instant access to recipe parameters, process telemetry, and equipment configuration data that lives in disparate systems. The AI deployment must connect to equipment monitoring platforms, pull historical performance baselines, and surface this context without requiring agents to leave their ticketing interface. This integration complexity is the primary deployment barrier for semiconductor OEMs evaluating contact center AI.

Initial pilot deployment takes 6-8 weeks including CRM integration, historical data ingestion, and model training on your equipment-specific cases. Production rollout across all case types typically completes within 4-5 months. This timeline assumes standard ticketing systems and existing equipment telemetry infrastructure.

The platform needs historical case data, equipment telemetry feeds from process tools, technical documentation including service manuals and troubleshooting guides, and knowledge base articles. For lithography and metrology equipment, recipe parameter data significantly improves triage accuracy. Most OEMs already collect this data—the deployment challenge is integration, not data availability.

The system analyzes case content for urgency signals like equipment status codes, production impact keywords, and SLA tier. High-severity fab downtime cases trigger immediate routing to senior specialists with relevant chamber expertise, bypass standard queue logic, and automatically assemble diagnostic context including recent telemetry anomalies and similar historical failures.

Yes. The platform connects to standard semiconductor equipment interfaces including SECS/GEM for tool communication and EDA systems for process data. This allows real-time correlation between equipment state and incoming support cases. Custom integration handles proprietary OEM telemetry formats through API connectors.

Agent headcount typically remains stable while workload composition shifts. Frontline agents handle more complex cases as AI resolves routine inquiries. Deployment requires a dedicated integration lead for 2-3 months, ongoing model training oversight, and periodic review of AI routing decisions. Most OEMs reassign rather than eliminate positions, moving staff to higher-value troubleshooting roles.

Transforming appliance support with AI-powered resolution.

Understanding and optimizing the issue resolution curve.

Vision AI solutions for EV charging support.

See how Bruviti integrates with your existing systems to reduce handle time and protect fab uptime.

Schedule Implementation Consultation