Global support teams need unified AI capabilities without disrupting existing service workflows across distributed equipment populations.

Deploy AI-powered contact center capabilities by integrating with existing CRM systems, training models on historical case data, and automating agent workflows. Industrial OEMs reduce average handle time while maintaining technical accuracy across global support teams serving distributed equipment installations.

Existing CRM and ticketing platforms contain decades of case history and agent knowledge. Legacy systems lack modern APIs, creating integration delays and data synchronization challenges that extend deployment timelines.

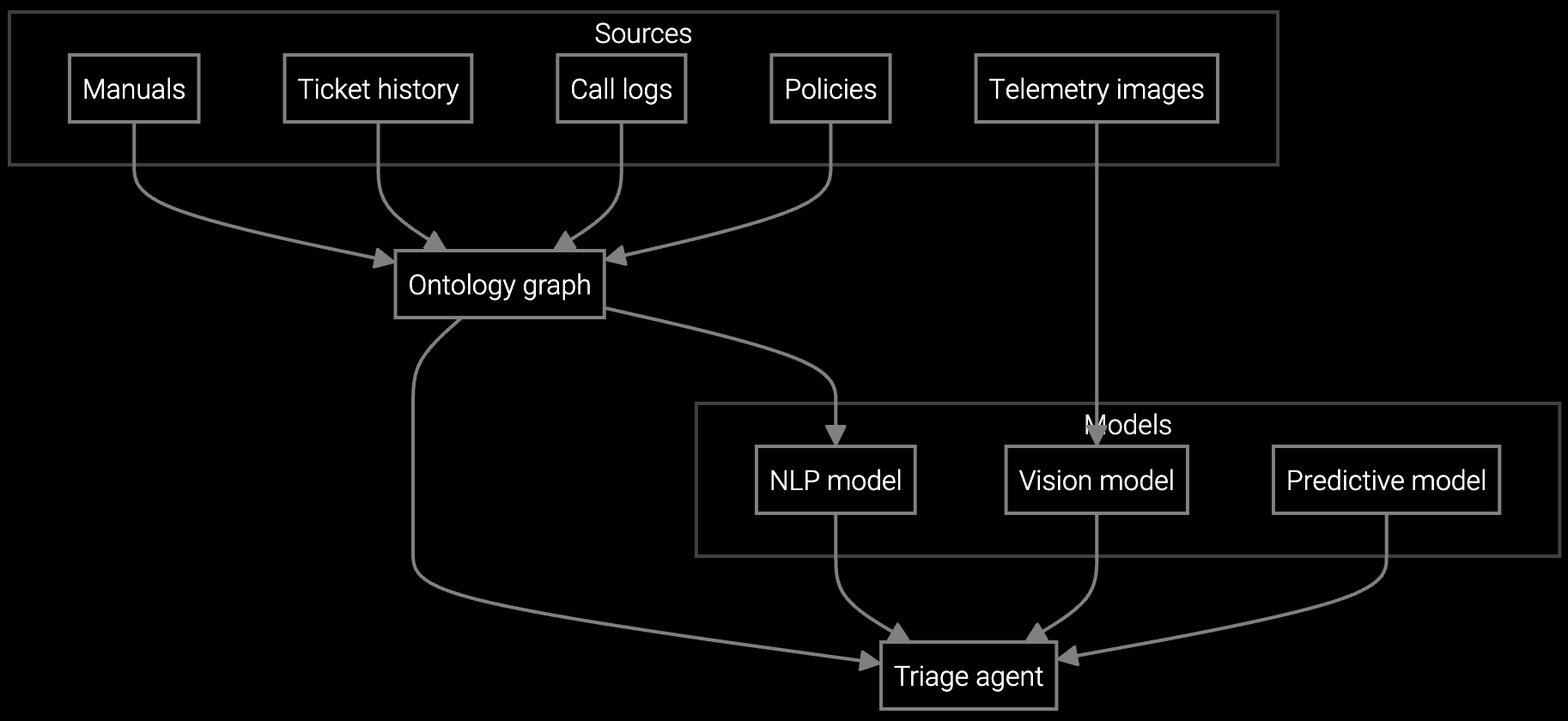

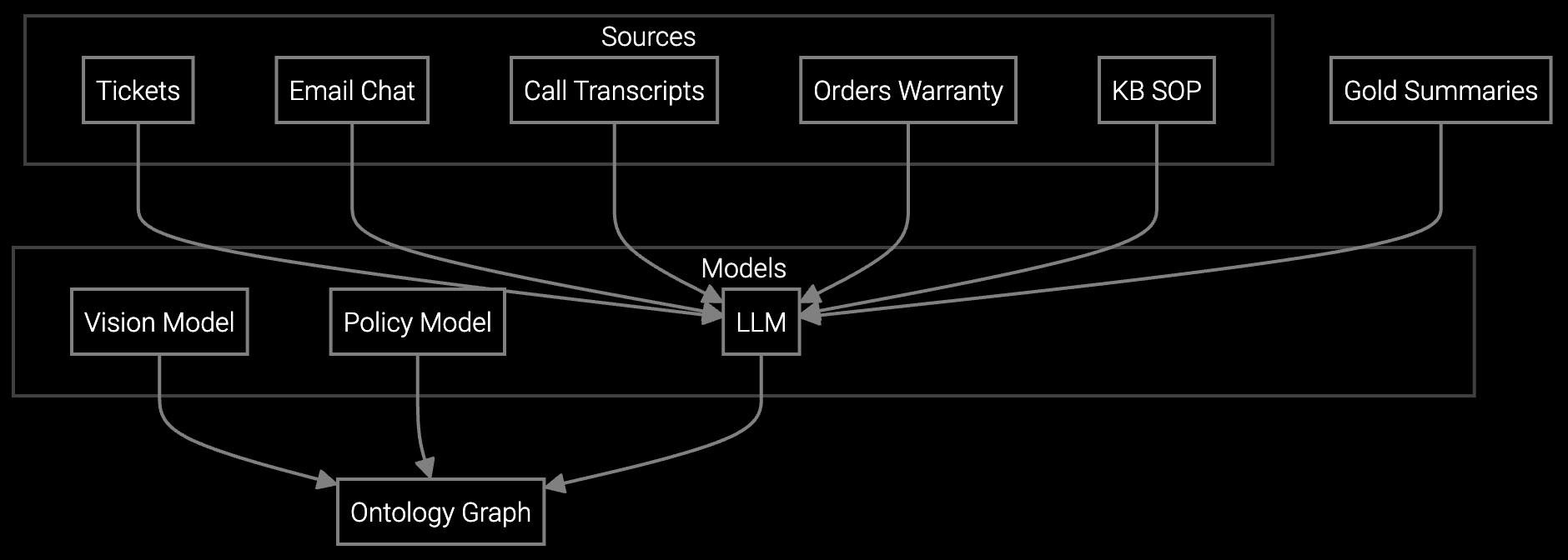

Generic AI models lack understanding of industrial equipment terminology, failure modes, and resolution procedures. Training models on historical case data requires data cleansing and technical expertise most contact centers lack in-house.

Agents resist tools that add complexity to existing workflows or fail to provide immediately useful guidance. AI implementations that require switching between multiple systems create productivity losses that undermine ROI projections.

Bruviti provides API-first integration with major CRM and ticketing systems, eliminating custom development work. Pre-built connectors for Salesforce, ServiceNow, and Zendesk enable data synchronization within weeks rather than months. The platform ingests historical case data, agent notes, and resolution outcomes to train models that understand your specific equipment terminology and service procedures.

Model training operates on your existing data without requiring manual cleansing or restructuring. The platform identifies patterns in successful case resolutions, extracting knowledge that agents can immediately access through embedded copilot interfaces. Agents receive contextual recommendations within their existing workflow, avoiding system-switching friction that typically undermines adoption rates.

Autonomous case classification analyzes equipment symptoms and operating conditions to route cases to agents with relevant machinery expertise, reducing misrouted cases and escalation rates.

Instant case summaries extract key details from multi-year equipment service histories, giving agents complete context for machinery with decades-long lifecycles without reading through hundreds of prior cases.

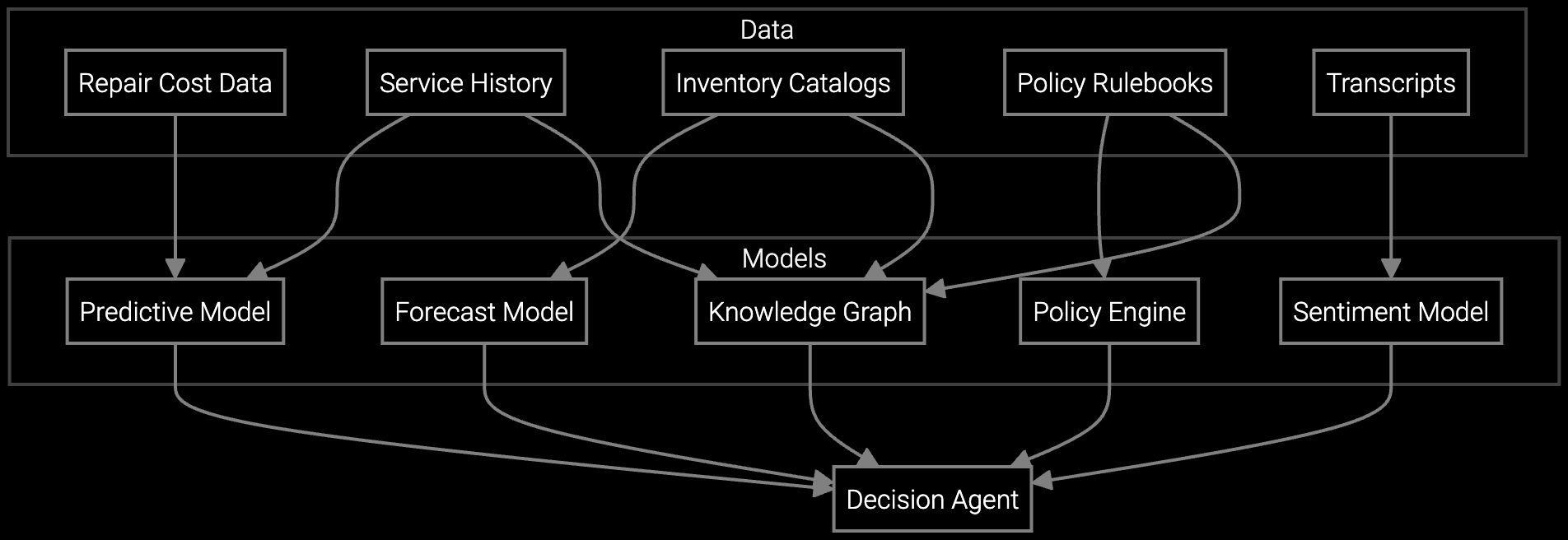

AI analyzes failure modes, part availability, and equipment age to recommend cost-effective resolution paths for aging industrial equipment, protecting margin on warranty cases and customer satisfaction decisions.

Industrial OEMs support equipment populations with 10-30 year lifecycles across global installations. Contact centers manage case volume spanning multiple machinery generations, each with distinct control systems and service procedures. Implementation must preserve institutional knowledge about legacy equipment while improving agent efficiency on current product lines.

Begin with highest-volume equipment families where agent handle time directly impacts cost per contact. Integrate CRM data for machinery with complete service histories, training models on resolution patterns that reflect actual field conditions. Deploy copilot capabilities to regional support centers first, validating technical accuracy before global rollout across distributed agent populations.

Typical deployment spans 3-4 months from contract signature to agent production use. The first 4-6 weeks cover CRM integration and historical data ingestion. Model training requires 6-8 weeks on your case history. Agent onboarding and pilot validation consume the final 4-6 weeks before full deployment across all support regions.

Pre-built connectors for Salesforce, ServiceNow, and Zendesk enable API-based integration without custom development. The platform synchronizes case data, agent notes, and resolution outcomes bidirectionally. IT teams configure authentication and data access permissions but avoid months of custom integration coding typical in enterprise AI deployments.

Track average handle time reduction across case types, first-contact resolution rate improvement, and cost per contact decrease. Industrial OEMs typically see 18-25% AHT reduction within 90 days on cases where agents use the copilot interface. Multiply saved agent hours by fully loaded labor cost to calculate margin protection from improved contact center efficiency.

Agents shift from searching for information to applying technical judgment on complex equipment issues. The platform handles routine knowledge lookup and case classification, freeing agents to focus on cases requiring equipment expertise and customer relationship management. Contact centers maintain headcount while handling increased case volume or reduce cost per contact by improving agent productivity.

Models train on decades of historical case data, learning resolution patterns for legacy machinery still in field operation. The platform validates recommendations against successful outcomes from experienced agents, ensuring technical accuracy across equipment generations. Agents can flag incorrect guidance, creating a feedback loop that continuously improves model accuracy for aging equipment populations.

Transforming appliance support with AI-powered resolution.

Understanding and optimizing the issue resolution curve.

Vision AI solutions for EV charging support.

Discuss integration timelines, model training requirements, and ROI projections for your global support operations.

Schedule Implementation Review