Seasonal HVAC surges and decades of SKU history demand flexible architecture—pure custom builds miss market windows.

Hybrid approaches deliver fastest time-to-value: use pre-trained models for standard workflows like symptom diagnosis and warranty triage, extend via Python SDKs for custom parts logic and legacy ERP integration, avoiding both slow internal builds and vendor lock-in.

Internal teams building from foundation models face 12-18 month development cycles. For appliance contact centers handling seasonal demand spikes, this timeline means missing peak-season readiness windows and absorbing avoidable support costs during critical periods.

Closed platforms trap custom logic inside proprietary workflow engines. When appliance manufacturers need to integrate decades of parts catalogs, model-specific troubleshooting trees, or legacy warranty systems, black-box solutions force expensive workarounds or data migration costs.

Appliance service AI must connect to SAP warranty systems, Oracle parts databases, and custom CRM platforms simultaneously. Pure-build approaches underestimate this integration burden, while closed platforms offer limited connector support for niche appliance manufacturer systems.

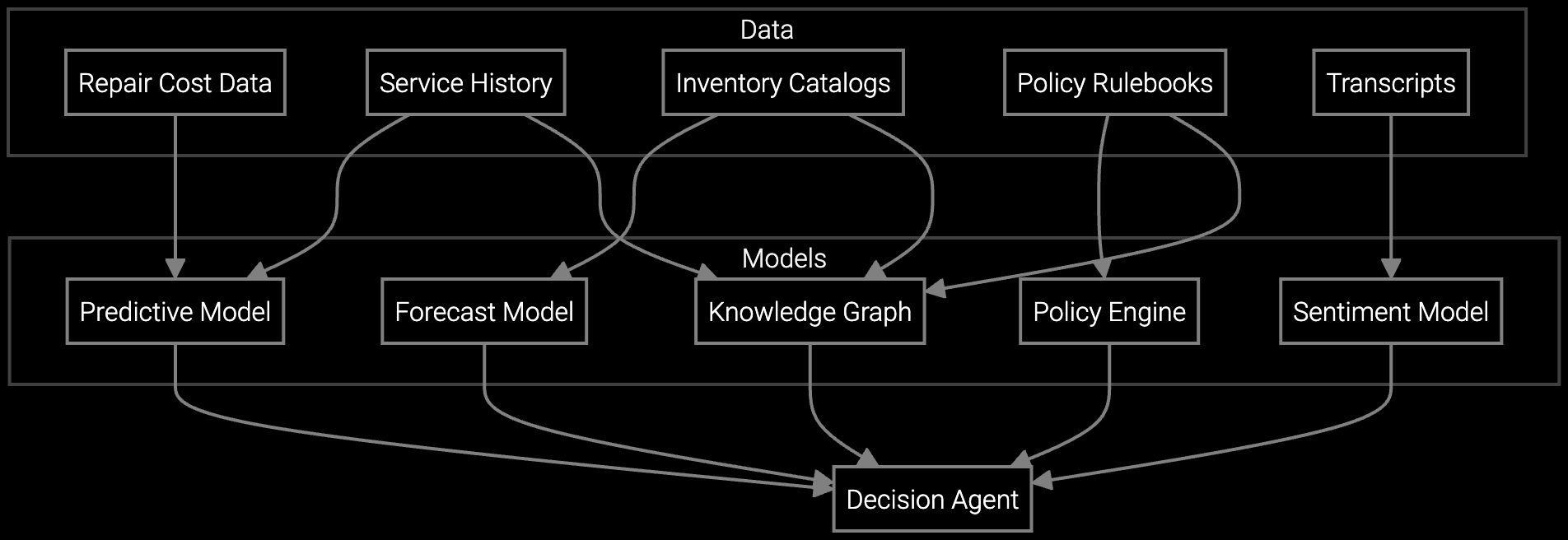

API-first platforms provide pre-trained models for universal contact center workflows—case classification, knowledge retrieval, response generation—while exposing Python and TypeScript SDKs for appliance-specific customization. This architecture means symptom-to-solution matching works immediately for common refrigerator or HVAC failures, while custom code handles model-year-specific parts compatibility or warranty entitlement rules unique to your product lines.

The platform handles the foundation model training, inference infrastructure, and security compliance, freeing internal teams to focus on differentiated logic: integrating decades of service bulletins, encoding brand-specific troubleshooting protocols, or building custom escalation rules for connected appliance telemetry. Developers write in standard languages against REST APIs, eliminating proprietary scripting languages and making the integration maintainable by existing engineering teams without specialized vendor training.

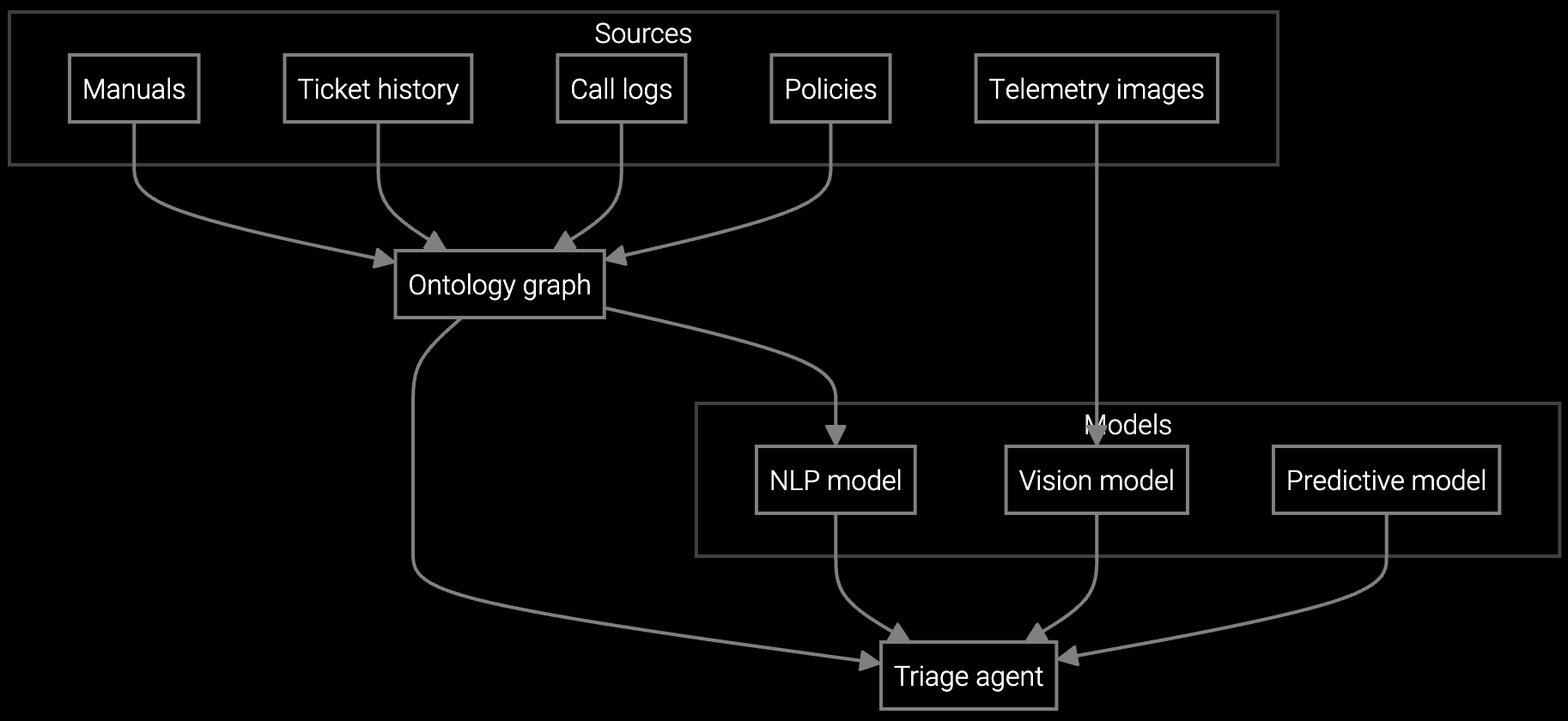

Pre-trained classification for appliance symptoms routes HVAC compressor failures, refrigerator ice maker issues, and washer error codes to specialized agent queues with diagnostic context already attached.

Automated email intake for warranty claims and service requests extends via SDKs to validate entitlement against your Oracle warranty system and attach model-specific troubleshooting guides before agent handoff.

Cost-benefit analysis integrates your parts pricing APIs and equipment age data to recommend repair or replacement paths, customizable for brand-specific customer satisfaction policies and warranty reserve strategies.

Appliance manufacturers manage contact centers supporting 30-40 year product lifecycles with parts catalogs spanning thousands of SKUs across refrigerators, washers, dryers, HVAC systems, and water heaters. Pre-built symptom analysis handles universal appliance failure modes—compressor noise, ice maker leaks, error code interpretation—while Python SDKs let your team encode model-year-specific parts supersession logic and integrate with legacy SAP warranty systems that closed platforms cannot access.

Seasonal demand creates architectural requirements closed systems miss: HVAC surges in summer require elastic scaling that API-first platforms support natively, while your custom code routes high-priority air conditioner failures during heat waves. Connected appliance telemetry integration happens via REST endpoints, feeding IoT sensor data into case context without vendor-specific connector delays or missing support for your proprietary appliance communication protocols.

Hybrid platforms deploy core contact center AI in 2-4 weeks using pre-trained models, with custom extensions added incrementally over 8-12 weeks. Pure builds require 12-18 months to train foundation models and build infrastructure. For appliance manufacturers, this timeline difference means capturing seasonal demand peaks versus missing entire HVAC cooling seasons.

SDKs expose case routing logic, knowledge retrieval ranking, and response generation hooks. Appliance teams use these to inject parts supersession rules, model-year compatibility checks, warranty entitlement validation, and brand-specific troubleshooting protocols. You write standard Python against REST APIs, not proprietary scripting languages, maintaining full code ownership.

API-first architecture means your custom logic lives in your codebase calling platform endpoints, not trapped inside vendor workflow engines. Data exports via standard REST APIs, and integration code uses open-source SDKs. Migration paths exist because you own the integration layer and can redirect API calls to alternative inference providers without rewriting business logic.

Core integrations include SAP or Oracle warranty systems for entitlement validation, parts databases for inventory availability, CRM platforms for customer history, and ticketing systems for case routing. Connected appliance deployments add IoT telemetry feeds. Hybrid platforms handle authentication and data transformation, while SDKs let you encode appliance-specific validation rules these systems require.

Pure builds justify investment when service AI becomes competitive differentiation requiring proprietary algorithms, or when regulatory constraints prohibit external inference APIs. For most appliance manufacturers, contact center AI is operational efficiency, not product differentiation—making time-to-value and integration flexibility more strategic than model ownership.

Transforming appliance support with AI-powered resolution.

Understanding and optimizing the issue resolution curve.

Vision AI solutions for EV charging support.

Review Bruviti's API documentation and SDK examples to assess integration complexity for your appliance service systems.

Request Technical Demo