Manual case routing and parts lookup consume agent time while equipment downtime costs your customers thousands per hour.

AI orchestrates end-to-end case workflows from intake through resolution, automating triage, parts lookup, and SLA tracking while preserving human oversight on complex decisions—reducing handle time and cost per contact across contact centers supporting global installed bases.

Agents spend minutes per case manually tagging equipment type, failure mode, and urgency level before work even begins. Inconsistent categorization causes misrouting and delays response to critical downtime events.

Agents toggle between CRM, parts database, maintenance manuals, and warranty systems to assemble context. Every screen switch adds seconds that compound into hours of lost productivity across the contact center.

Different agents interpret escalation criteria differently, creating uneven workload distribution and delays for time-sensitive cases. No systematic handoff process means context gets lost and work gets repeated.

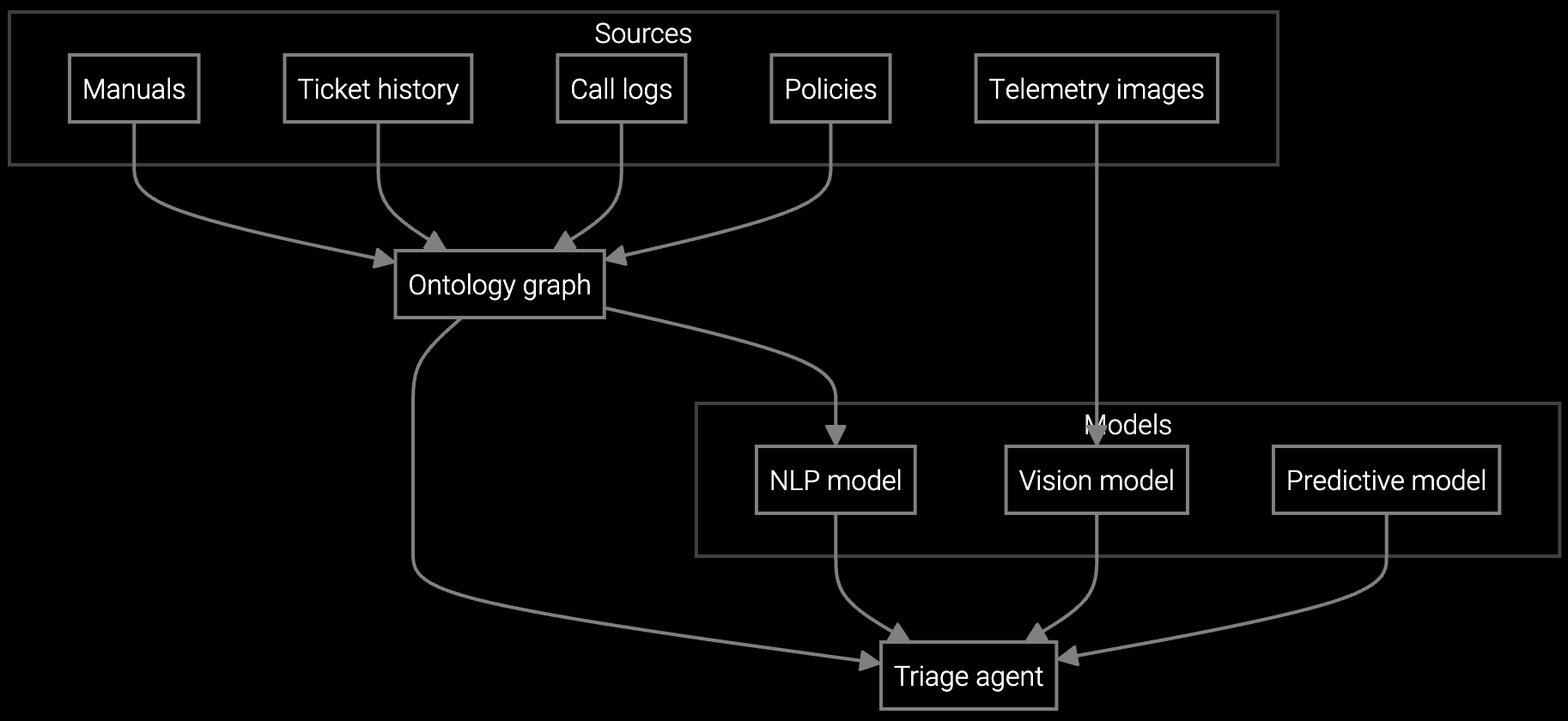

Bruviti automates the entire case lifecycle from intake through resolution. The platform ingests customer emails, phone transcripts, and equipment telemetry, instantly classifying case type and urgency while pulling relevant maintenance history, parts availability, and warranty status into a unified workspace. Agents receive pre-populated case notes and recommended actions rather than navigating multiple systems.

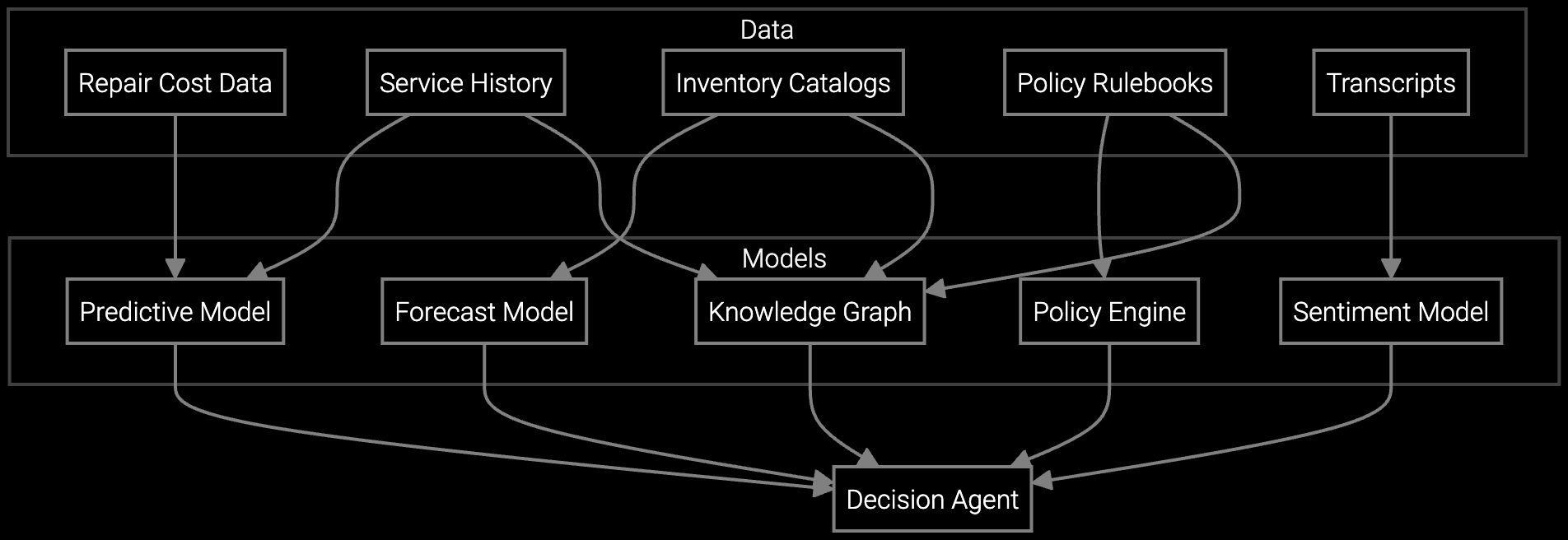

For routine requests like parts ordering or return authorization, AI executes the entire workflow autonomously—verifying entitlement, checking inventory, generating documentation, and updating case status. Complex cases receive the same automated context assembly but route to specialized teams with full diagnostic support. This orchestration reduces average handle time while improving first contact resolution rates and maintaining compliance audit trails.

Automatically processes inbound equipment failure reports from plant managers, extracting machine serial numbers, error codes, and operating conditions to create fully classified cases with pre-populated diagnostic context.

Routes high-pressure pump failures to hydraulics specialists and CNC spindle issues to precision mechanics based on equipment type, failure symptoms, and customer production schedule impact.

Analyzes equipment age, run hours, failure mode, and replacement part availability to recommend the most cost-effective resolution path while equipment sits idle in the customer's production line.

Industrial OEMs support thousands of machines deployed across global facilities, each with unique operating conditions, maintenance histories, and production priorities. A CNC machine failure at an automotive supplier carries different urgency than the same failure at a job shop. Contact center agents must interpret customer context, assess equipment criticality, and coordinate responses across time zones while customers face mounting downtime costs.

Equipment lifecycles spanning decades mean agents field questions about legacy machinery with limited documentation. Parts availability varies by region and supplier relationships. Warranty coverage depends on maintenance compliance and operating conditions. Every case requires synthesizing information from multiple systems while the customer waits and their production line sits idle.

The platform eliminates manual tasks like case classification, knowledge base searches, and system navigation that consume agent time without adding value. By auto-populating case context and executing routine workflows end-to-end, agents handle more cases per shift while reducing handle time. Lower handle time directly reduces labor cost per contact while maintaining or improving first contact resolution rates.

Routine transactional workflows like parts ordering, return authorizations, warranty lookups, and status updates execute autonomously when criteria are clear and risk is low. Complex diagnostics, escalation decisions, and customer negotiations receive AI-prepared context but require human judgment. The platform learns which cases it can resolve independently based on historical outcomes and confidence thresholds.

The platform logs every automated decision, data access, and action taken with timestamps and justification. Warranty determinations, parts replacements, and return authorizations document the data sources and logic used. This creates complete audit trails for financial reporting, warranty reserve analysis, and regulatory compliance without manual documentation overhead.

The platform connects to Salesforce, ServiceNow, SAP, and other enterprise systems via APIs to access customer history, equipment records, and case data. It orchestrates workflows across these systems without replacing them, creating a unified agent experience while preserving existing data structures and business processes. Integration happens in weeks, not months.

Track average handle time reduction, first contact resolution improvement, and cases per agent per day before and after deployment. Calculate labor cost savings by multiplying handle time reduction by hourly agent cost and annual case volume. Add margin protection from improved SLA compliance and reduced customer downtime. Most industrial OEMs see positive ROI within six months.

Transforming appliance support with AI-powered resolution.

Understanding and optimizing the issue resolution curve.

Vision AI solutions for EV charging support.

See how workflow automation reduces cost per contact while protecting margins through faster case resolution.

Schedule Demo