Fab downtime costs $1M+ per hour—every minute agents spend searching manuals instead of resolving cases delays production recovery.

Automate case triage and knowledge retrieval to reduce handle time. AI analyzes equipment symptoms, surfaces exact fixes from technical docs, and auto-populates case notes—turning agents into validators rather than researchers.

Agents toggle between PDFs, wikis, and CRM systems hunting for chamber PM procedures or recipe parameter fixes. Each search adds minutes to already-long handle times.

Equipment history, prior alarms, and telemetry data live in separate systems. Agents piece together the full story from fragments, delaying diagnosis.

Every closed case requires copying symptom descriptions, resolution steps, and parts ordered into structured notes. This admin work consumes time better spent on the next case.

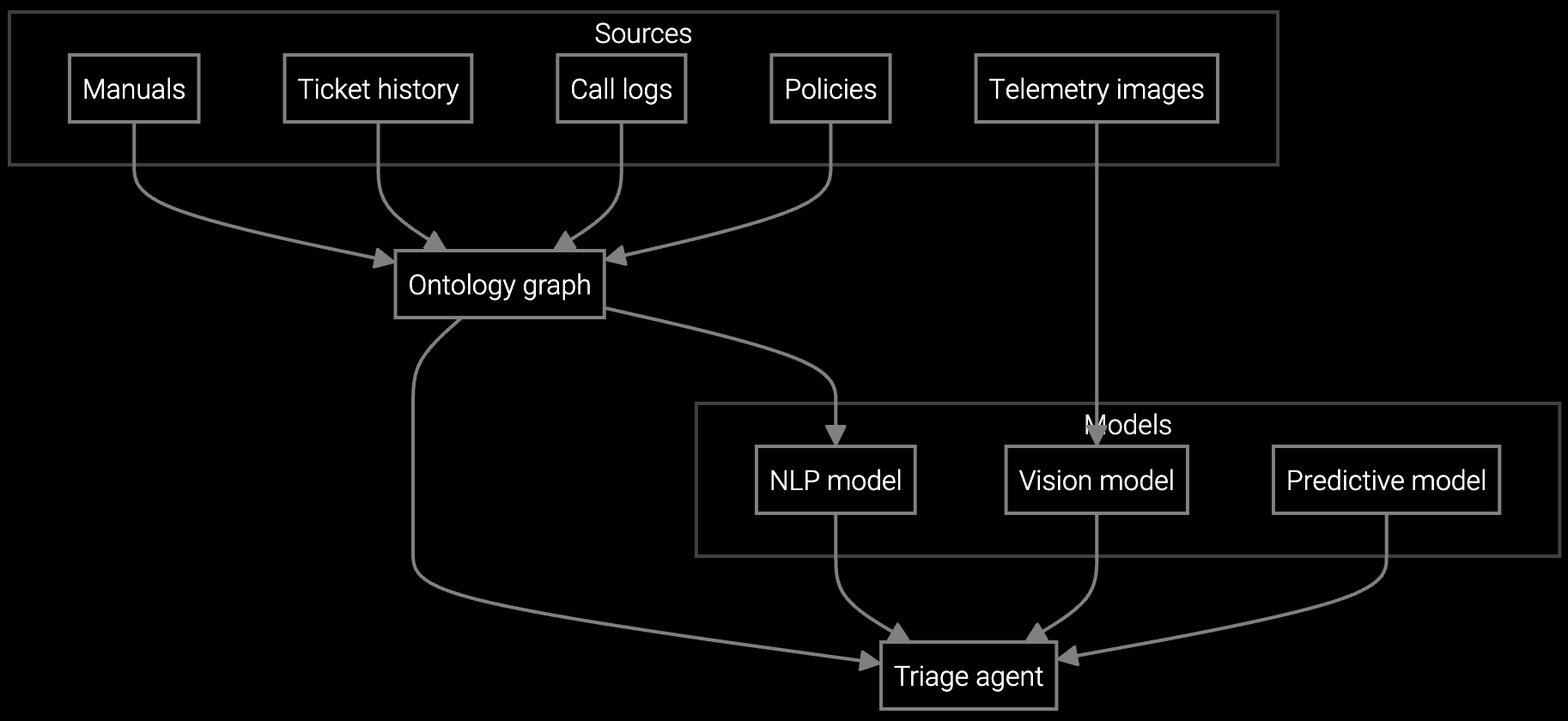

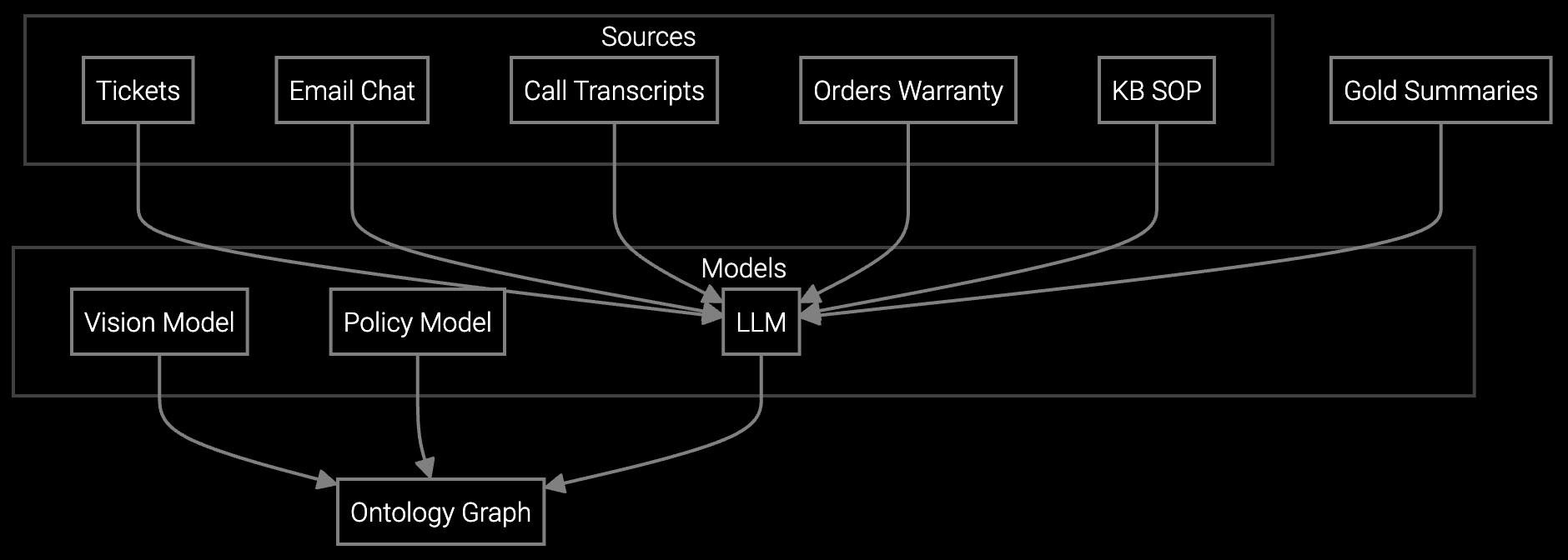

The platform analyzes incoming case descriptions, correlates them with equipment telemetry and alarm codes, and retrieves the most relevant troubleshooting steps from technical documentation. Agents see a unified resolution panel with chamber-specific procedures, historical fix patterns, and recommended parts—no manual searching required.

As agents work through the case, the platform automatically drafts structured case notes capturing symptoms, actions taken, and resolution outcome. Agents review and click submit rather than typing from scratch. The system learns from closed cases, improving suggestion accuracy over time and reducing reliance on tribal knowledge.

Autonomous classification analyzes fab equipment symptoms, correlates chamber telemetry, and routes cases to the right specialist team with diagnostic context already attached.

Instantly generates case summaries from email chains, chat logs, and prior ticket history so agents understand full equipment context without reading every message.

AI reads incoming support emails, classifies by urgency and equipment type, and drafts responses using historical resolution data and technical documentation—agents review and send.

Semiconductor OEM support teams handle cases where every minute of downtime costs fab customers six figures. Agents field questions about chamber recipes, process drift, contamination sources, and PM schedules across dozens of tool models. Technical documentation runs hundreds of pages per tool, and resolution accuracy matters as much as speed—sending the wrong chamber kit or misdiagnosing a contamination event compounds fab downtime.

The platform ingests process telemetry, alarm logs, and PM histories alongside structured technical docs. When a case arrives about yield degradation on an etch tool, agents see correlated alarm patterns, recent recipe changes, and the exact PM procedure for that chamber model—without opening five different systems or asking a senior engineer.

The platform retrieves model-specific troubleshooting guides and surfaces similar historical cases for that tool family, giving agents instant expertise regardless of their personal experience. They validate AI-suggested resolutions rather than starting from zero.

When symptoms indicate on-site intervention is needed, the platform auto-generates a complete handoff package including telemetry snapshots, attempted remote fixes, and recommended parts for the dispatch. This eliminates back-and-forth clarification between teams.

Yes. Agents review suggestions and can modify or reject them. When an agent applies a different fix, the platform learns from that decision and improves future recommendations. The system augments agent judgment rather than replacing it.

The platform processes cases from all channels. Email and chat inputs are analyzed directly; phone transcripts convert to text for symptom extraction. Agents see the same unified resolution panel regardless of how the case arrived.

The system surfaces the closest analogs from historical cases and highlights gaps in available documentation. Agents can flag novel issues for expert review, and those resolutions feed back into the knowledge base for future cases.

Transforming appliance support with AI-powered resolution.

Understanding and optimizing the issue resolution curve.

Vision AI solutions for EV charging support.

See how semiconductor OEMs automate knowledge retrieval and case documentation for their support teams.

Schedule Demo