Fab customers demand sub-hour response times. Your agents need AI that integrates with legacy systems without forcing a platform rip-and-replace.

Hybrid approach wins: API-first platforms provide pre-trained models for speed while avoiding vendor lock-in through open integration. Start with case triage, extend with custom Python logic, measure by FCR improvement within 90 days.

Training foundation models from scratch requires annotated case data at scale. Most semiconductor OEMs lack the 100K+ labeled cases needed for production-grade accuracy, pushing initial deployment 18+ months out.

Closed platforms like Salesforce Service Cloud trap your data in proprietary schemas. Migrating case history, custom workflows, and integrations off-platform costs 3-5x the original implementation spend.

Semiconductor service data lives in SAP PM, Oracle EBS, custom MES systems, and equipment telemetry feeds. Point-to-point integrations multiply maintenance burden as systems evolve.

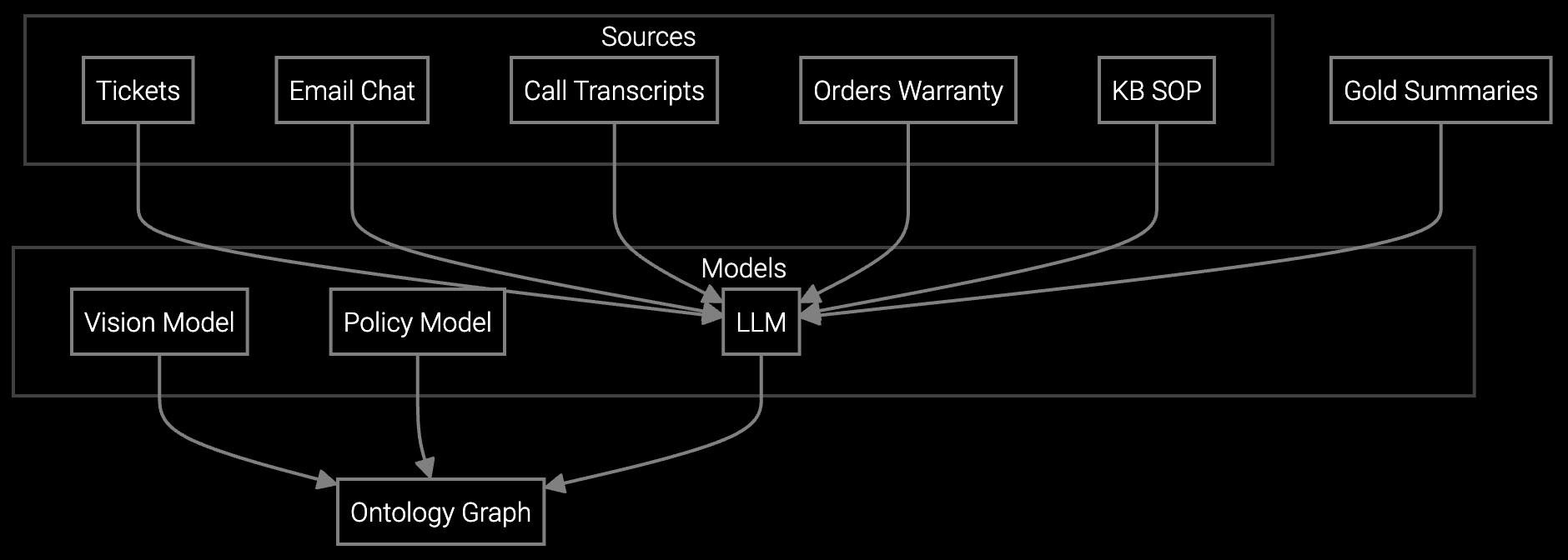

API-first platforms deliver pre-trained models fine-tuned on aftermarket service data while exposing Python and TypeScript SDKs for custom extension. This eliminates the 18-month training cycle without sacrificing technical control. You integrate via REST APIs and GraphQL endpoints, not proprietary connectors that lock you in.

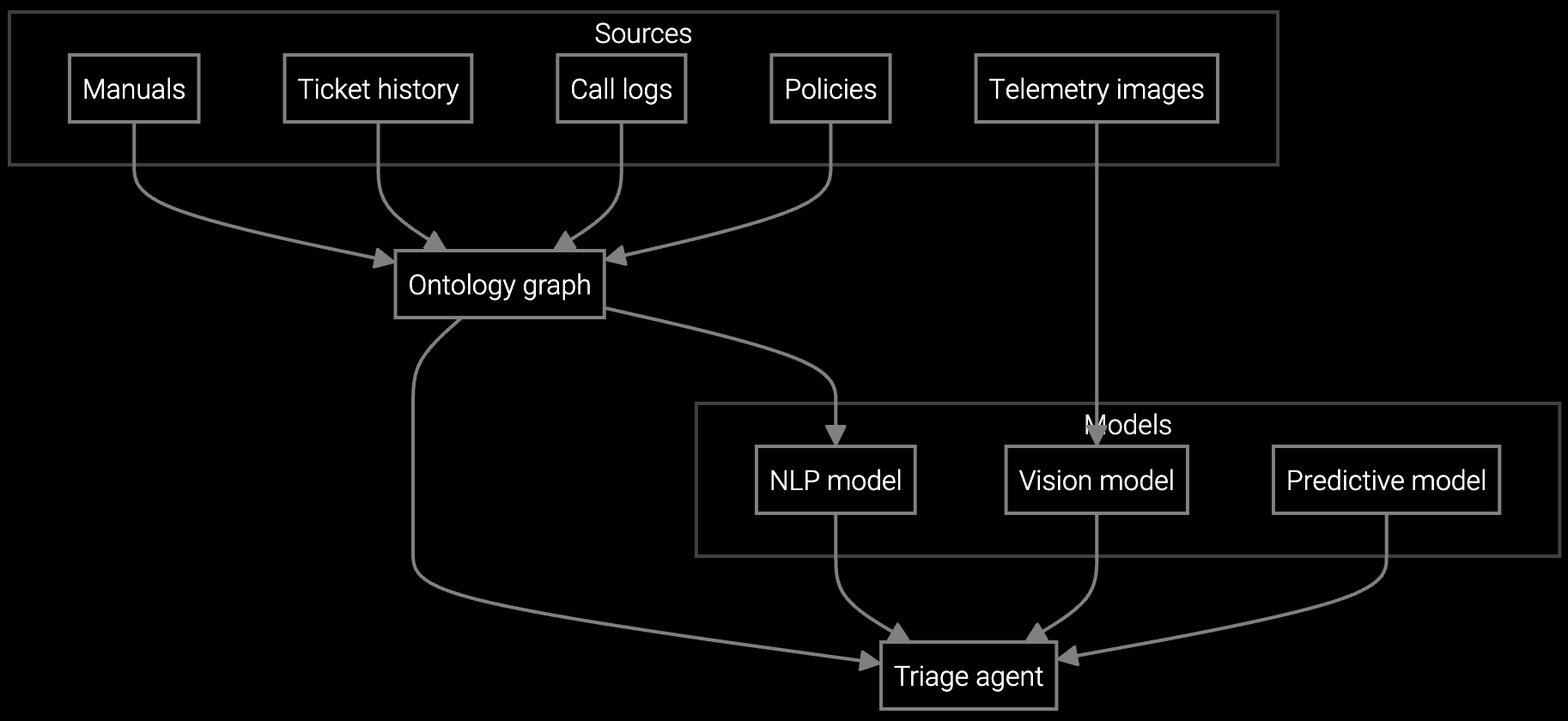

Bruviti's platform connects to SAP, Oracle, and custom data lakes through standard protocols. Case routing logic runs in your Python scripts, calling our classification models as services. Your agents see results in their existing CRM, not a new UI they must learn. When you need to tweak the model for semiconductor-specific failure modes, you retrain using our SDK and your annotated data, then deploy the custom version without vendor approval cycles.

Autonomous case classification for semiconductor tool issues, routing chamber PM alerts to process engineers and contamination reports to cleanroom specialists based on symptom patterns and telemetry correlation.

Instant summaries of multi-week escalations involving recipe drift, equipment logs, and FAE email threads, giving new agents full context without reading 40+ messages and attachments.

AI reads fab customer emails describing yield drops, correlates with equipment performance data, and drafts responses with diagnostic steps and recommended process adjustments based on historical case outcomes.

Semiconductor OEMs face unique AI strategy challenges. Your customers run 24/7 fabs where every minute of lithography tool downtime costs $50K+. They demand instant access to process engineers who understand their specific recipe and chamber configuration, not generic contact center agents reading scripts.

This creates pressure to build custom AI that understands etch rates, deposition uniformity, and metrology data. But training models on this specialized data requires annotation by scarce process engineers, the same people already overloaded with escalations. A hybrid strategy resolves this: start with pre-trained case routing, then fine-tune on your labeled data as your team annotates high-value examples over time.

Choose platforms with full data export capabilities and open SDKs. API-first architectures let you build custom routing logic that calls AI models as services, so your code stays independent of the vendor. Test the export process during proof-of-concept: can you download training data, model weights, and integration configs without vendor approval? If not, you're locked in.

Foundation model training requires 100K+ annotated cases minimum for production accuracy. Most semiconductor OEMs have the raw data but lack annotations, requiring 6-12 months of manual labeling by engineers. Add 6 months for model architecture design, training infrastructure setup, and iteration. Total time to production: 18-24 months before first agent sees value.

Yes, if the platform exposes SDKs for fine-tuning and custom classification layers. Bruviti's Python SDK lets you load your annotated examples, retrain the model on semiconductor failure modes, and deploy custom versions alongside the base model. You control which cases route to which model version based on equipment type or failure category.

Use platforms with REST APIs and standard authentication protocols like OAuth2. You build lightweight middleware that fetches case data from SAP PM via SAP's REST APIs, passes it to the AI classification endpoint, then writes routing decisions back to your CRM. Avoid platforms requiring custom connectors that break when SAP versions change.

Start with high-volume, low-complexity cases where AI accuracy is easy to validate. Chamber preventive maintenance triage works well: symptoms map clearly to maintenance schedules, success is binary (right team or wrong team), and you can measure impact via FCR improvement within 90 days. Avoid starting with rare escalations or complex yield issues where model errors are expensive.

Transforming appliance support with AI-powered resolution.

Understanding and optimizing the issue resolution curve.

Vision AI solutions for EV charging support.

Run a 30-day proof-of-concept on your actual case data. Export everything at the end—no risk, no lock-in.

Schedule Technical Demo